Composite method for casting and rolling composite plate of steel, cupper, and graphite

A composite plate and graphite technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of composite forming and inability to coil, and achieve the effect of composite forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

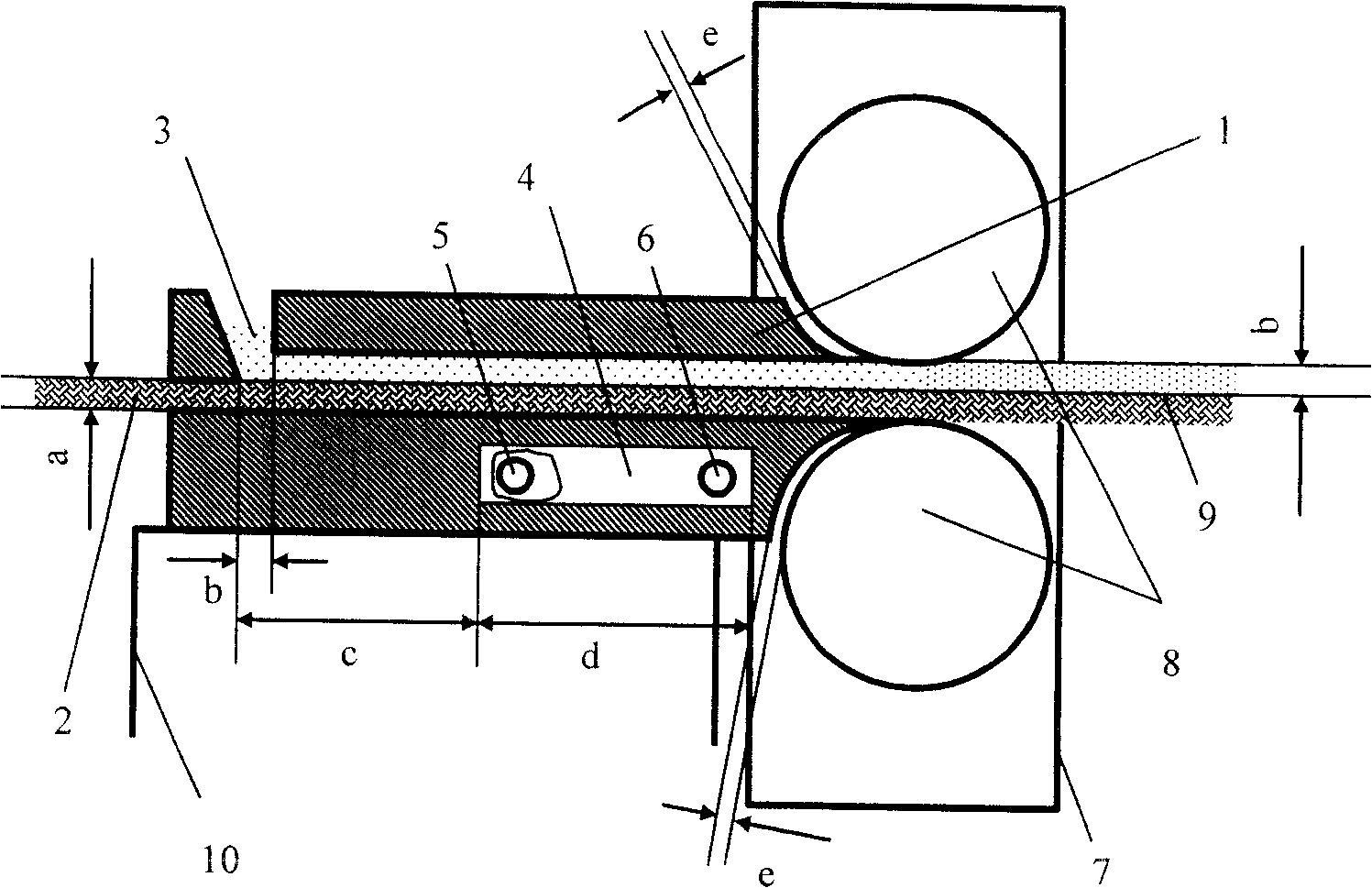

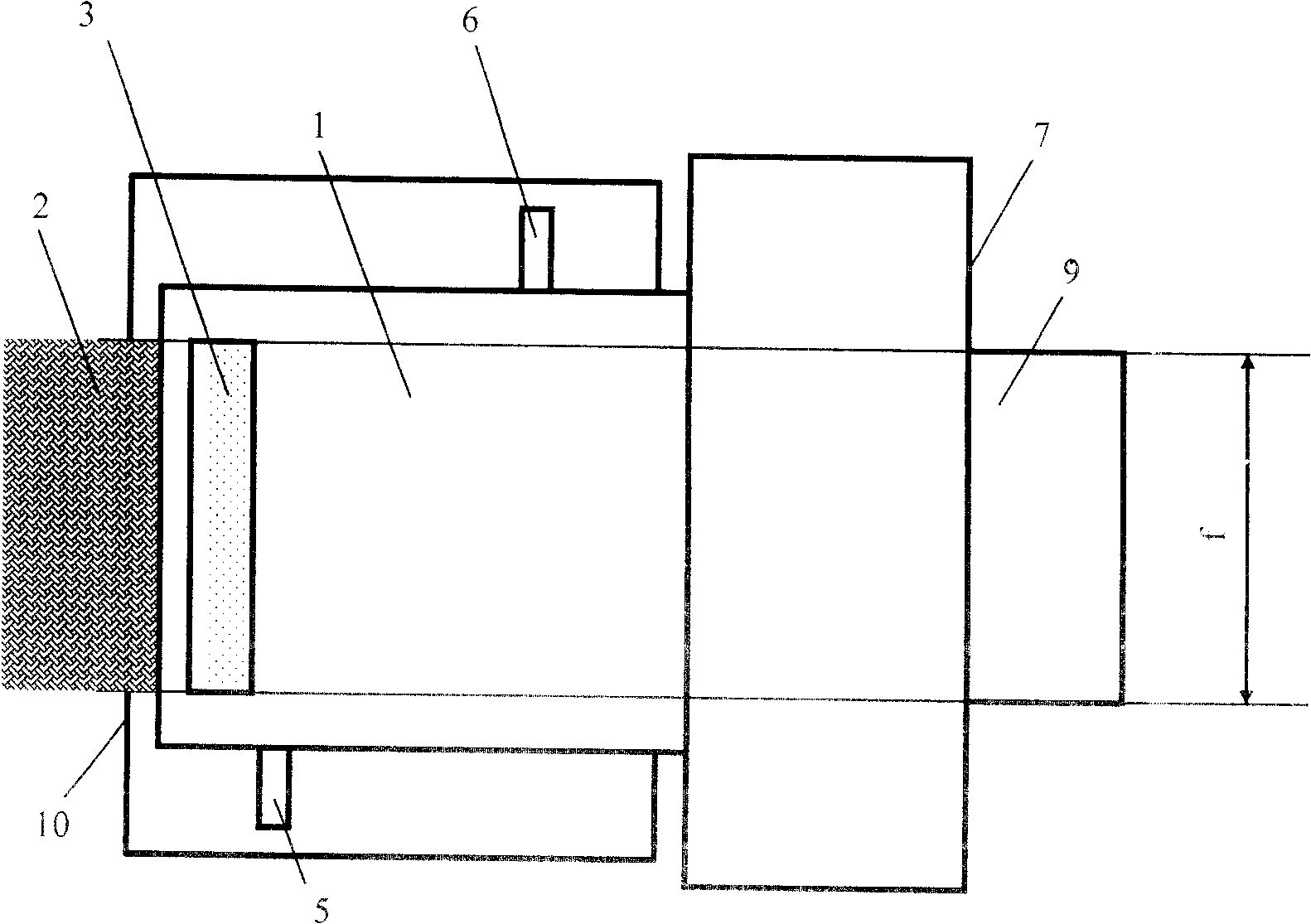

Embodiment approach 1

[0024] Step 1, preheat the steel plate whose surface has been degreased, derusted, roughened, and dip-coated to 550°C, and the thickness of the steel plate is 1.2mm;

[0025] Step 2, connect the composite gate and the water cooling system of the rolling mill roll, the cooling rate of the cooling chamber is 400°C / min, the cooling rate of the rolling mill roll is 300°C / min, and the diameter of the rolling mill roll is 320mm;

[0026] Step 3, start the rolling mill, adjust the rolling speed to and keep it at the speed of realizing "running rolling";

[0027] Step 4, pouring titanium bronze 3.5-3.5 graphite semi-solid slurry with a solid phase rate of 40%, performing "running and rolling", the thickness b of the copper-graphite semi-solid slurry flow channel is 1.3mm;

[0028] Step 5, after "running and rolling" for 1 minute, reduce the rolling speed so that the steel plate and the titanium bronze 3.5-3.5 graphite coating can be diffused for 40 seconds, then cooled in the cooling ...

Embodiment approach 2

[0030] The difference from Embodiment 1 is: the preheating temperature of the steel plate is 600°C, the solid phase ratio of the titanium bronze 3.5-4 graphite semi-solid slurry is 45%, and the diffusion time between the steel plate and the titanium bronze 3.5-4 graphite coating is 35s , The cooling rate of the cooling chamber is 450°C / min, the cooling time is 35s, the cooling rate of the rolling mill roll is 350°C / min, the interface shear strength of the obtained steel titanium bronze 3.5-4 graphite composite plate is 128MPa.

Embodiment approach 3

[0032] The difference from Embodiment 1 is: the preheating temperature of the steel plate is 650°C, the solid phase ratio of the titanium bronze 3.5-5 graphite semi-solid slurry is 50%, and the diffusion time between the steel plate and the titanium bronze 3.5-5 graphite coating is 30s , The cooling rate of the cooling chamber is 500°C / min, the cooling time is 30s, the cooling rate of the rolling mill roll is 400°C / min, the interface shear strength of the obtained steel titanium bronze 3.5-5 graphite composite plate is 126MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com