Integral refuse compressor

A garbage compressor, integrated technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of reducing the service life of equipment, reducing equipment use efficiency, long construction period, etc., to achieve stable up and down operation of the box, simplify the production level, The effect of reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

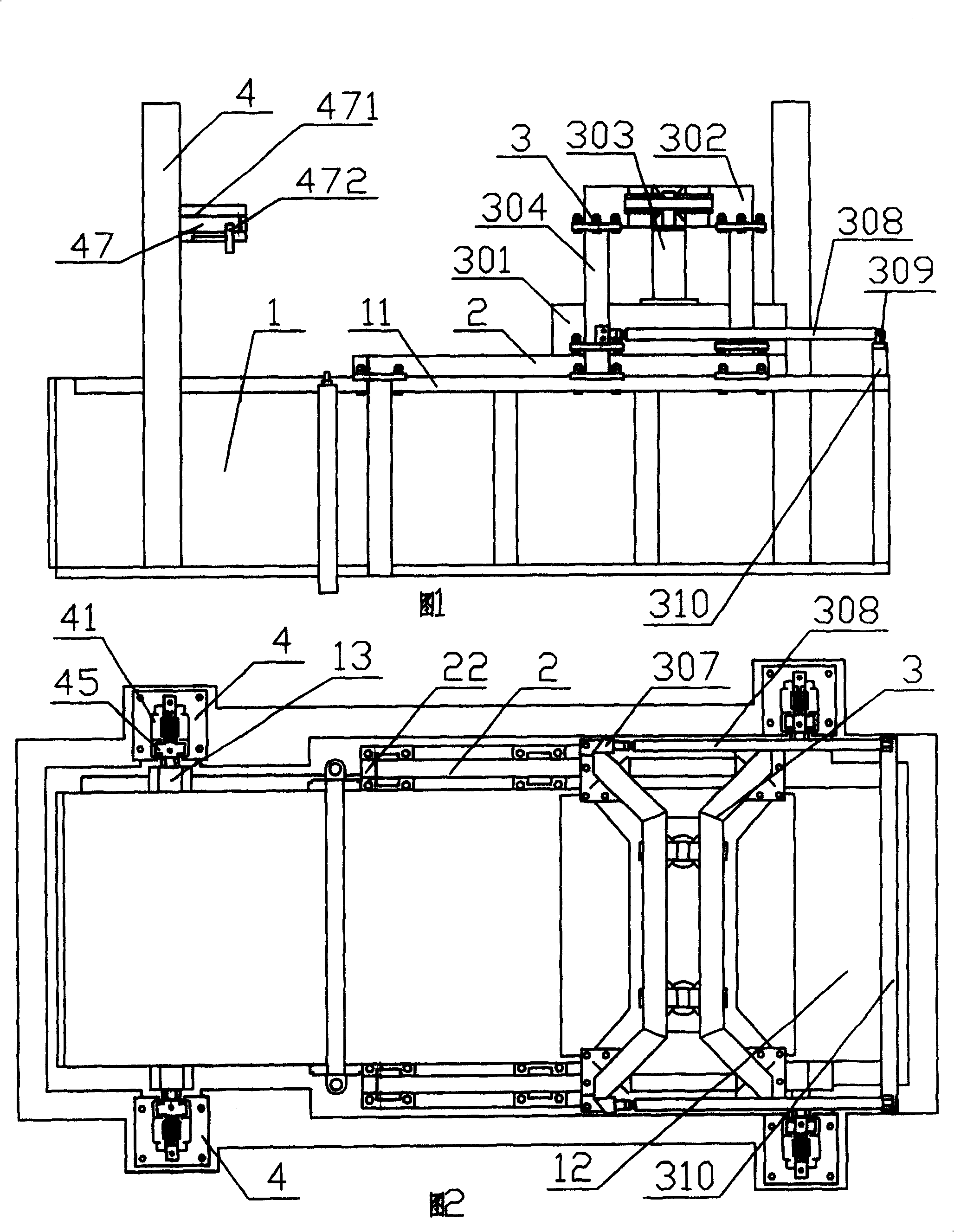

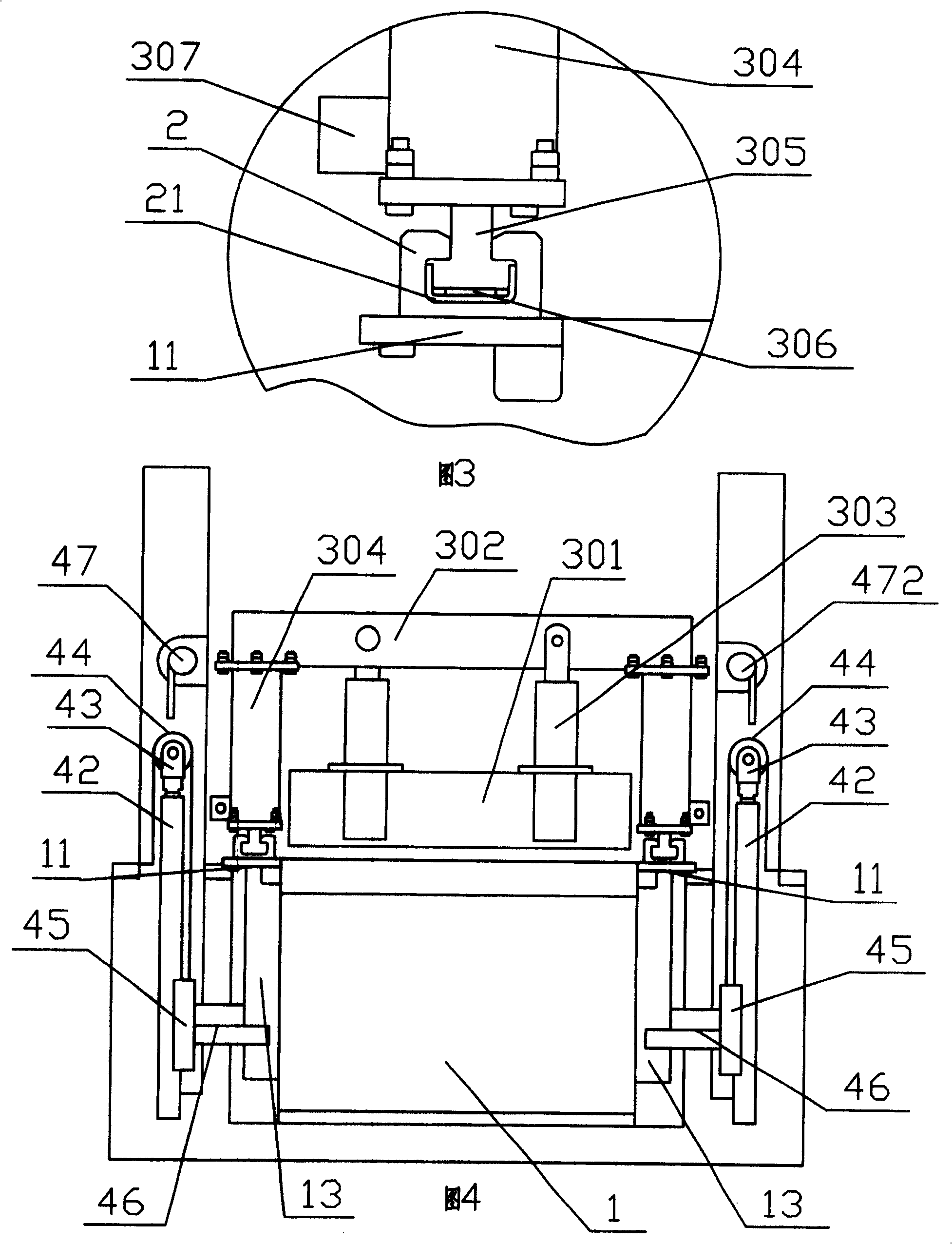

[0020] The structure of the present invention is shown in Fig. 1 to Fig. 4 . Description of icon numbers: dustbin 1, upper edge 11, upper cover plate 12, pressing rod 13, compression device 3, pressing table 301, girder 302, oil cylinder 303, column 304, slider 305, wear-resistant plate 306, sliding seat 307, sliding oil cylinder 308, rear seat 309, guardrail 310, guide rail 2, track 21, limit block 22, lifting mechanism 4, concave column 41, lifting oil cylinder 42, wheel base 43, sprocket wheel 44, guide body 45, Crosspiece 46, safety mechanism 47, support seat 471, safety bar 472.

[0021] The integrated garbage compressor includes a garbage bin 1 and a lifting mechanism 4 matched with it for lifting. These two mechanisms are placed in a preset pit to make the ground of the entire garbage transfer station clean and convenient for dumping a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com