Process for preparing high silicon stalloy by pack siliconizing process

An electrical steel sheet, embedding and infiltration technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of reducing elongation, restricting the production and processing of high-silicon steel, and achieving the solution to technological difficulties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

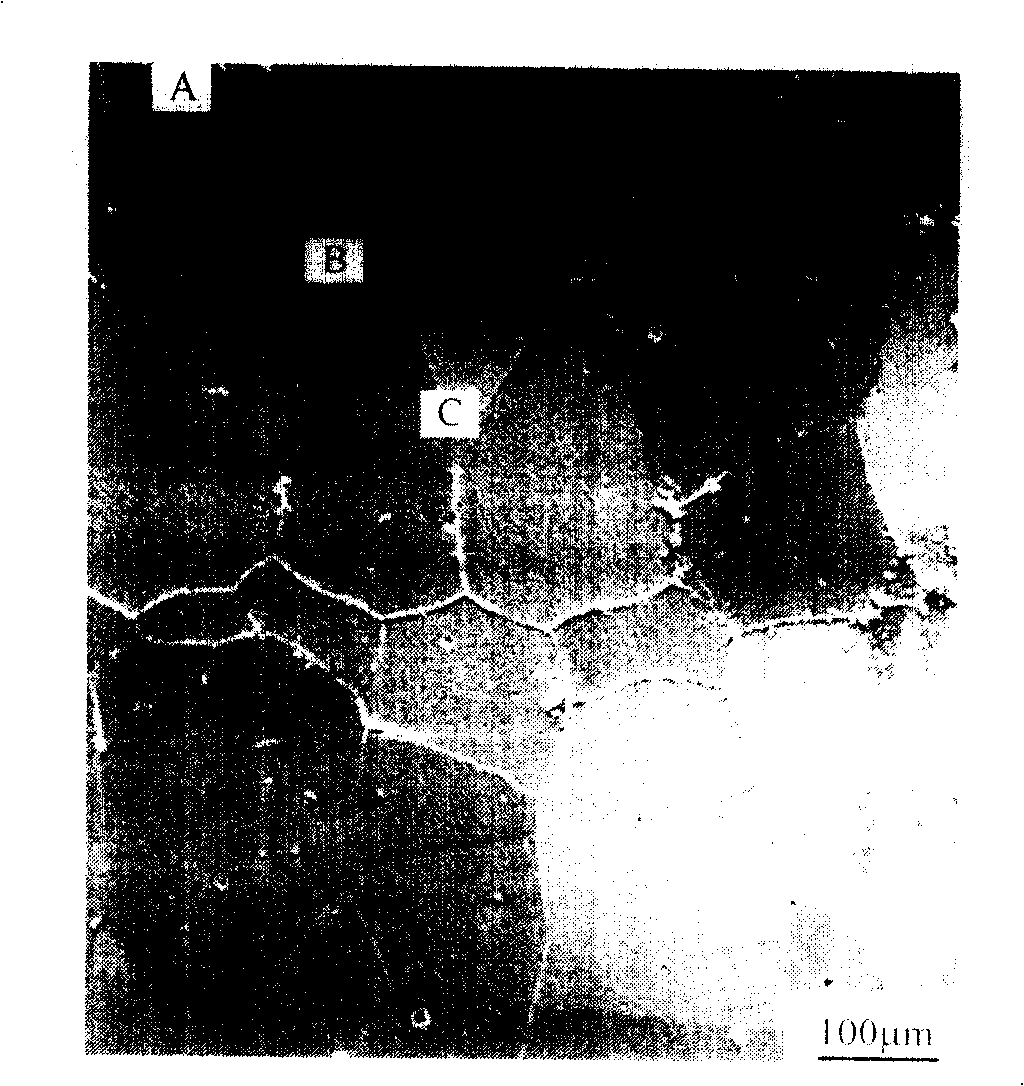

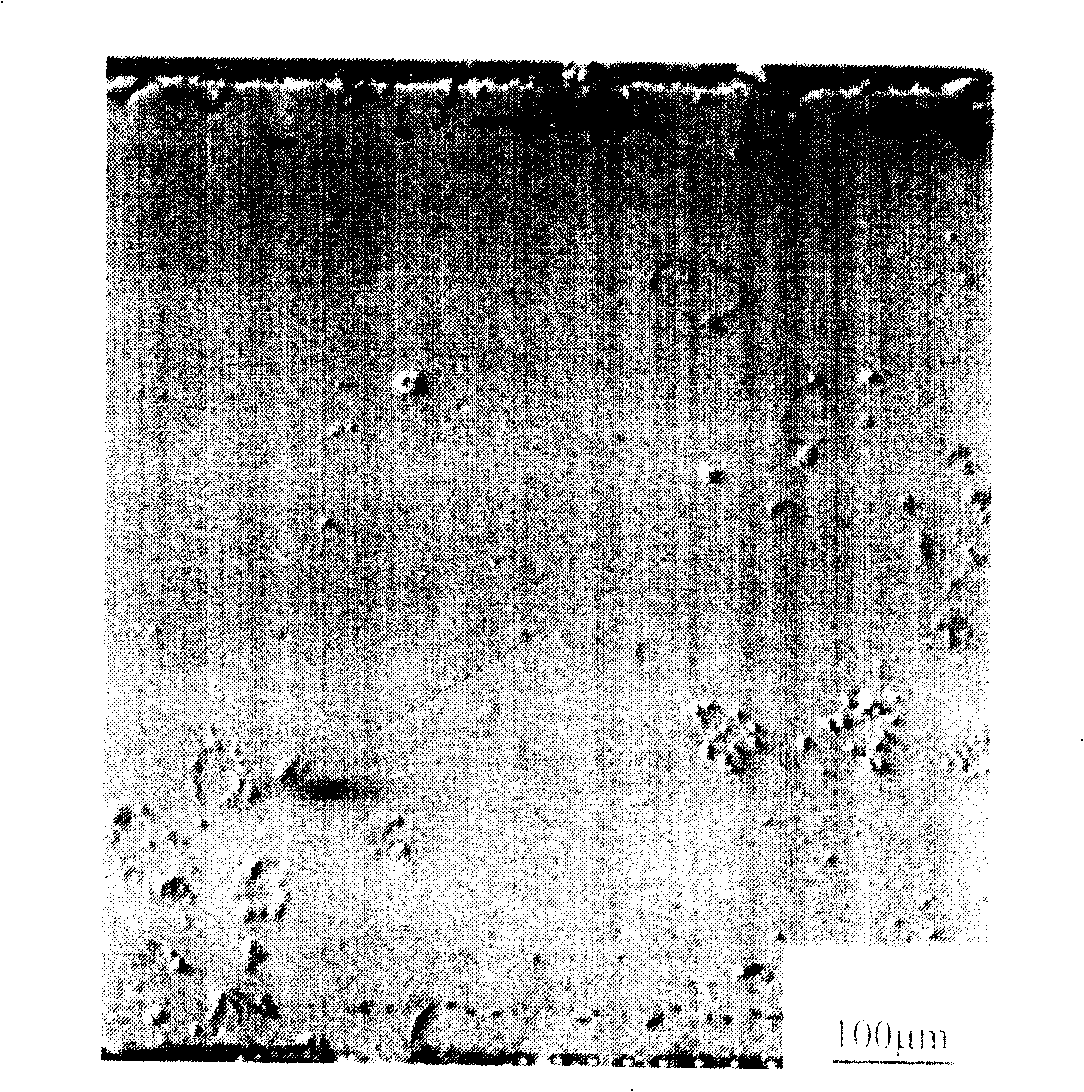

Image

Examples

Embodiment 1

[0034] 80g siliconizing agent consists of 3g of sodium fluoride NaF, 9g of silicon Si powder (Si powder particle size 200 mesh) and 68g of aluminum oxide Al 2 o 3 composition, and put the prepared siliconizing agent into an oven at 100°C for 1 hour, to be used;

[0035] Select two non-oriented "EI" type 0.5mm thick low-silicon steel sheets with a silicon content of 0.5%, and polish them, put them in alcohol, store them for 1 hour, take them out, dry them with cold wind, and set them aside;

[0036] Put 10g of siliconizing agent into the bottom of the crucible, then put a piece of low-silicon steel sheet, and sprinkle 10g of siliconizing agent evenly around and above it; then put another piece of low-silicon steel sheet, and fill it evenly around and above The rest of the siliconizing agent is put into the heat treatment furnace after covering and strengthening the crucible lid;

[0037] Infuse protective gas - argon for 10 minutes;

[0038] Adjust the heating rate of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com