Steam combustion-supporting type torch burner

A torch combustion and steam technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of unsatisfactory smoke elimination effect, inability to take noise reduction measures, huge noise, limited ability to eject air, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

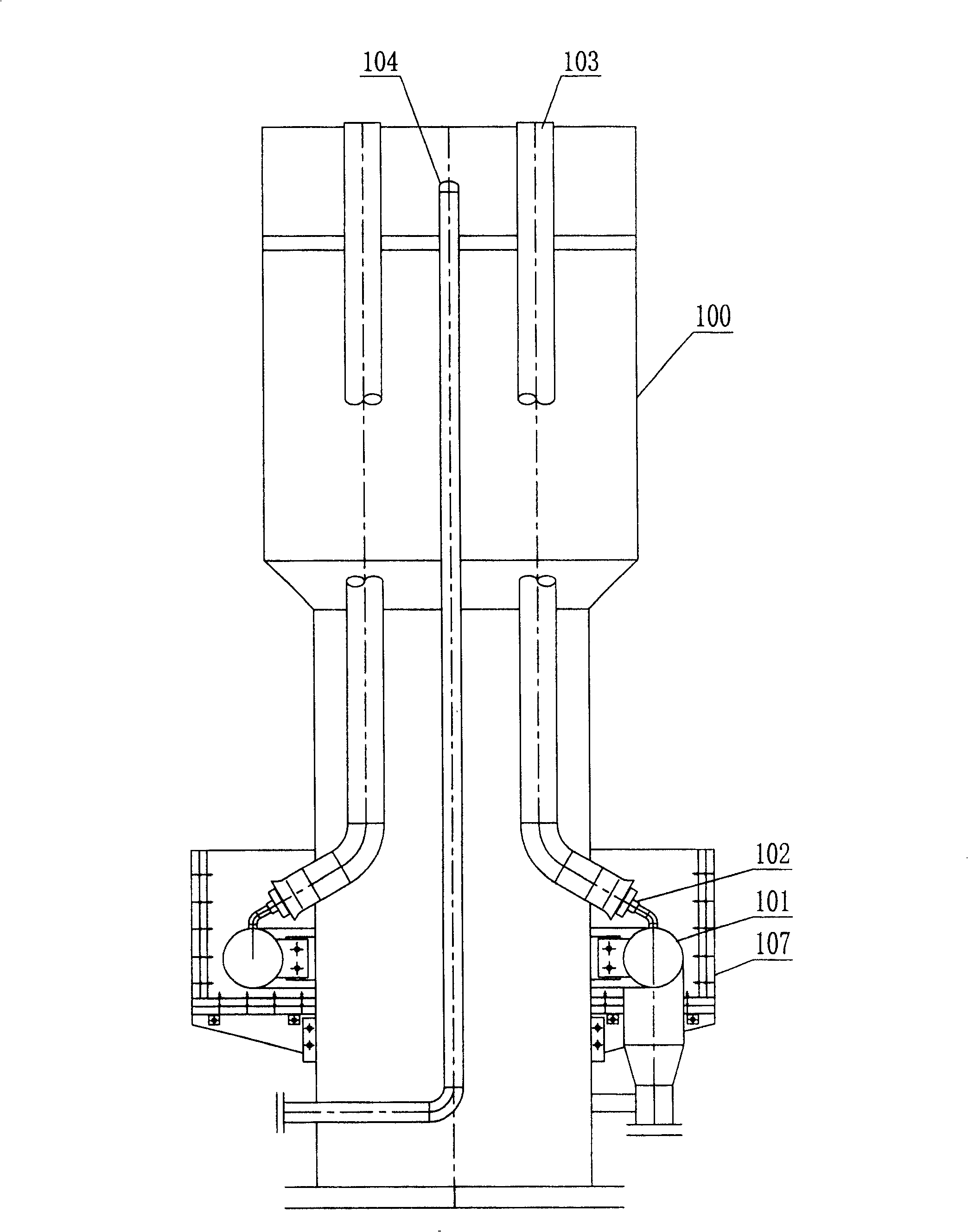

[0024] Such as figure 1 As shown, the first embodiment of the steam-assisted torch burner of the present invention mainly includes a cylinder body 100, a water vapor ring pipe 101 surrounding the cylinder body 100, a plurality of nozzles 102 fitted with the water vapor ring pipe 101, and steam air The injection pipe 103 and the nozzle 102 are respectively adjacent to and aligned with the entrance of the steam air injection pipe 103. The nozzle 102 can be a plum blossom nozzle, and the water vapor ring pipe 101 is away from the top of the burner, for example, it can surround the cylinder at the bottom of the burner set up. The water vapor enters the water vapor ring pipe 101, and then is sprayed out through the nozzle 102, and a large amount of air is entrained into the steam air injection pipe 103, and the high-speed ejected water vapor and the entrained air are uniformly mixed through the steam air injection pipe 103 and then sent To the top of the flare burner, to participa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com