Engine throttle position sensing method and sensor

A technology of throttle position and sensing method, which is applied in the field of position sensing to achieve the effect of eliminating the influence of factors such as the environment, improving accuracy and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

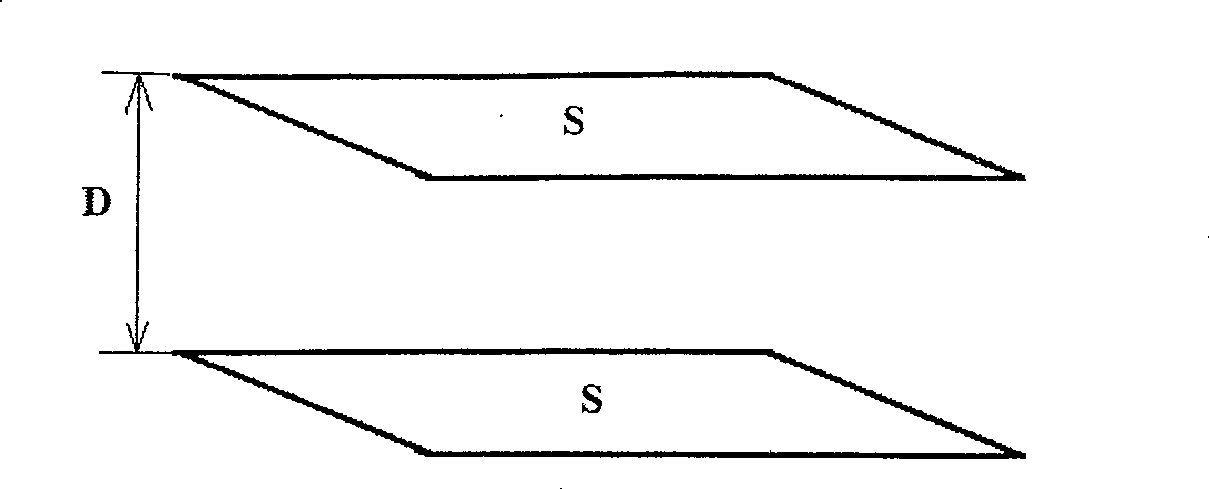

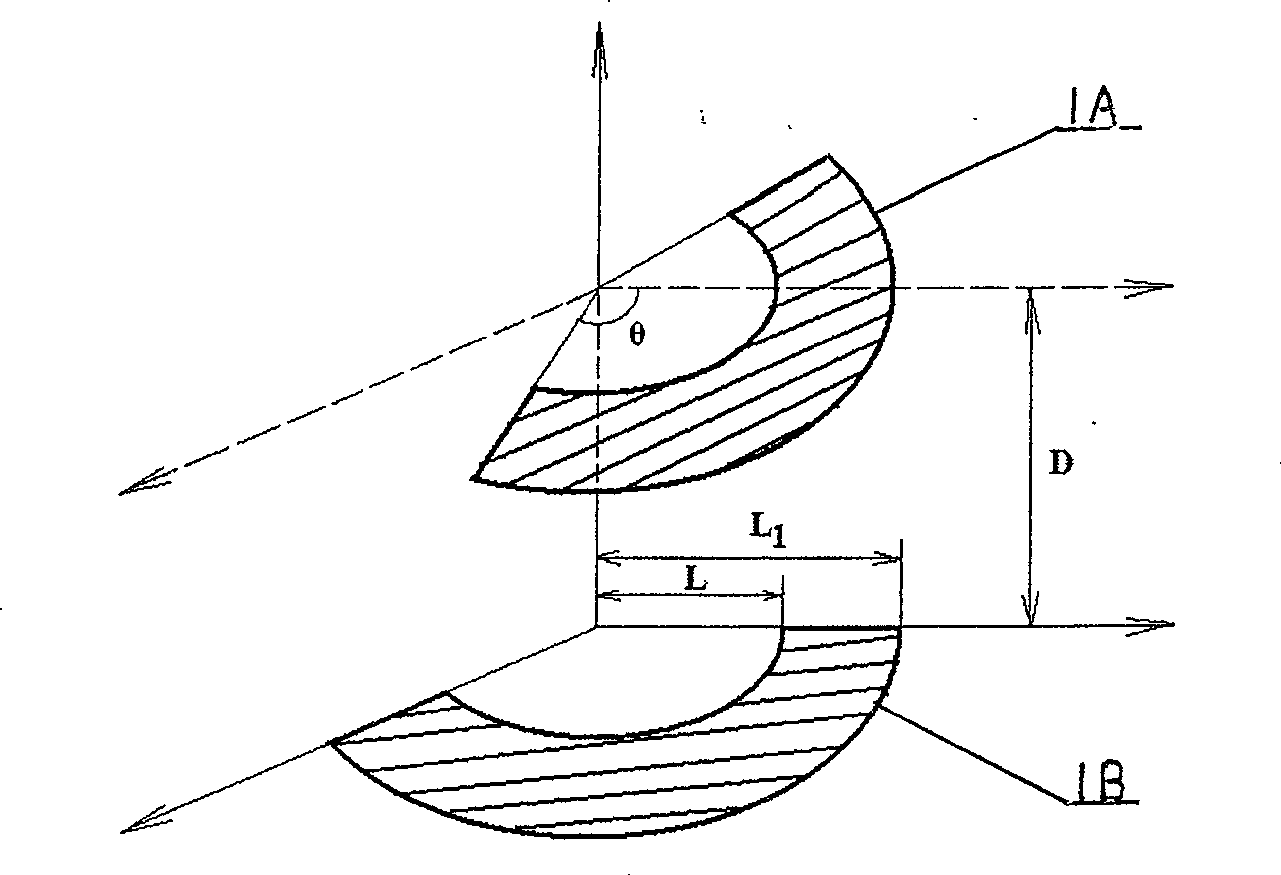

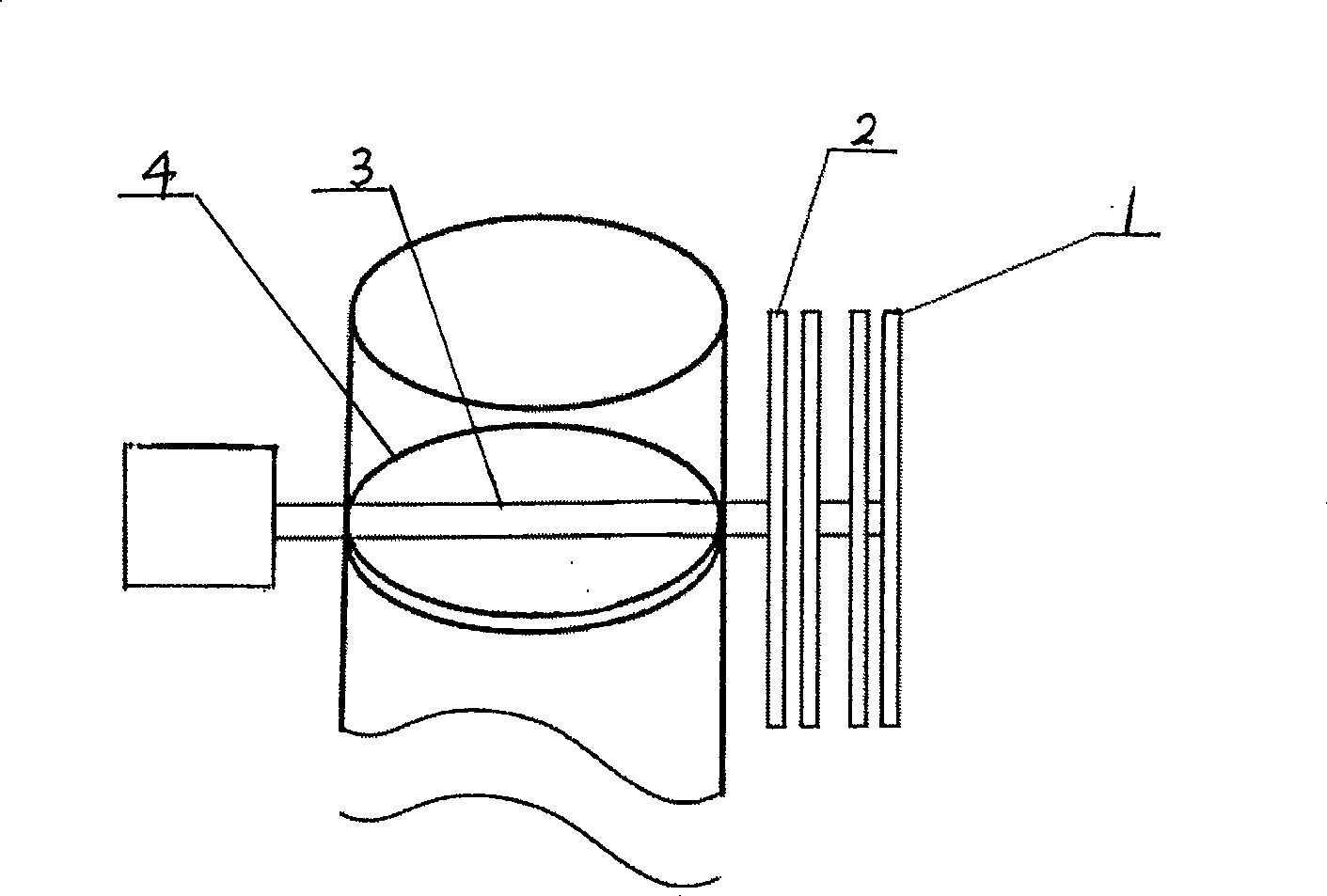

[0047] see image 3 and Figure 4 , The automobile engine throttle position sensor is composed of a measuring capacitor, a reference compensation capacitor and a processing circuit. Measuring capacitor 1 is an adjustable parallel plate capacitor. In order to facilitate circuit processing, a fan-shaped plate dielectric can be used, such as figure 2 As shown, the inner and outer ring radii of the two fan-shaped plate dielectrics are the same. One pole plate 1A of the measurement capacitor 1 is fixedly connected with the throttle shaft 3 and rotates coaxially with the throttle valve 4, and the other pole plate 1B is fixedly installed in the capacitor housing base 5 fixed on the throttle body 6, two pieces The pole plates are installed coaxially and keep the axial distance constant. The reference compensation capacitor 2 is a parallel plate capacitor whose capacitance value is constant during normal operation, and its capacitance value is equal to or has a certain proportional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com