Cast paint spraying machine

A casting coating and spraying machine technology, applied in casting molding equipment, coatings, manufacturing tools, etc., can solve the problems of unable to maintain the dimensional accuracy of castings, unable to ensure spray quality, unable to quantitatively control the spray amount, etc., to facilitate cleaning and maintenance, The effect of civilized production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

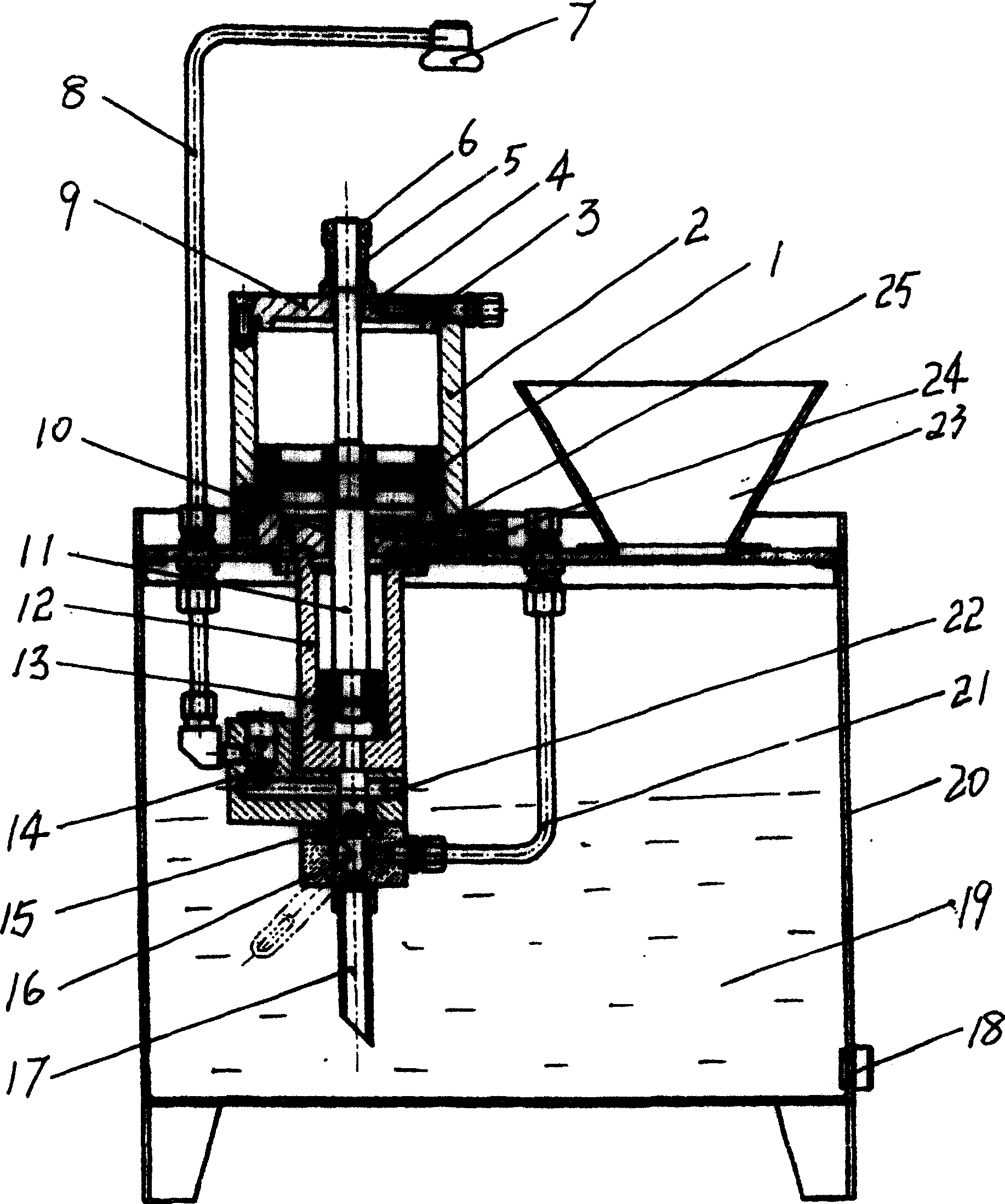

[0018] see Figure 1 ~ Figure 3 , its working process is: connect the cylinder body 2 with the air pressure (or hydraulic pressure) and the control system, the pressure fluid inlet and outlet 25 intake air, the power piston 1 moves upward, the suction and injection piston 13 moves upward, and the one-way valve 15 opens , the suction pipe 17 sucks the paint into the suction and spray cylinder 12, and the air outlet 24 exhausts the air. When the power piston 1 travels to the top dead center, the liquid suction action is completed; the inlet and outlet 3 of the pressure fluid are sucked into the air, and the power piston 1 moves toward The downward movement, the suction and spray piston 13 moves downward, and the nozzle 7 is placed in the proper position of the mold. The suction and spray piston 13 presses the paint into the nozzle 8 and the nozzle 7, and the paint is evenly sprayed in a 180° plane shape. When the 1 line reaches the bottom dead center, the spraying action is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com