Technique for strengthening boundary face of functional gradient material of shield duct piece by using FRP rib

A technology of functionally graded materials and shield segments, applied to structural elements, building components, manufacturing tools, etc., to achieve the effects of ensuring stability, prolonging service life, and saving processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

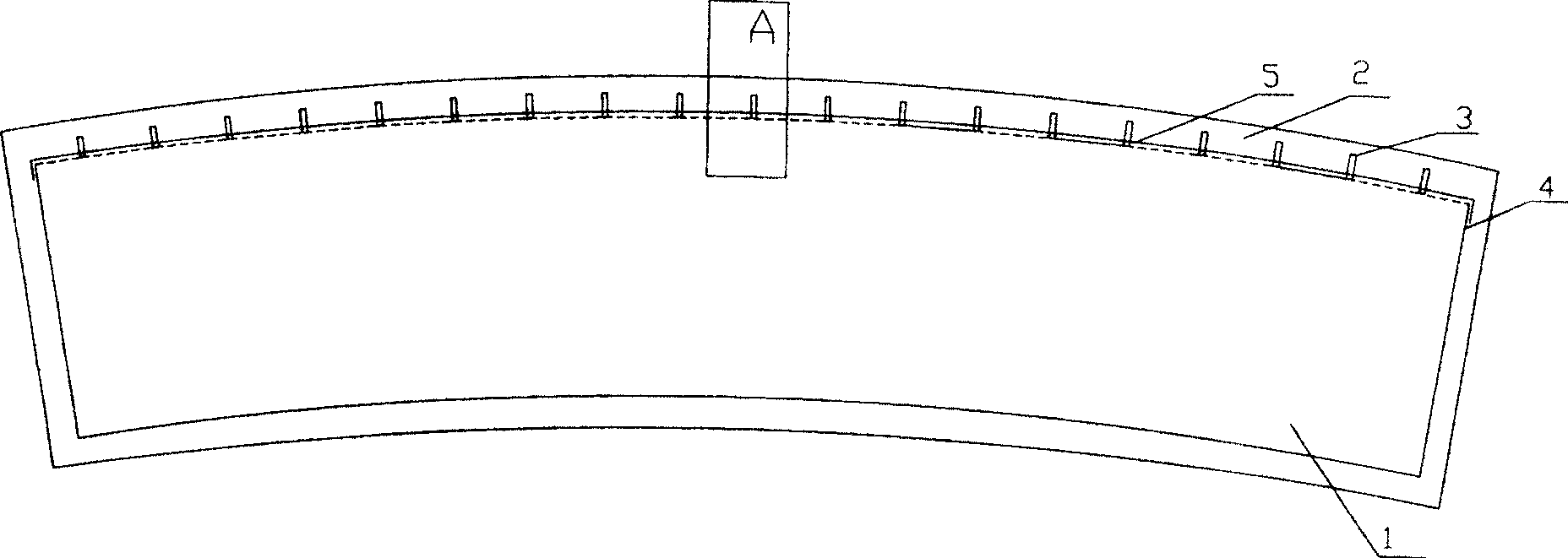

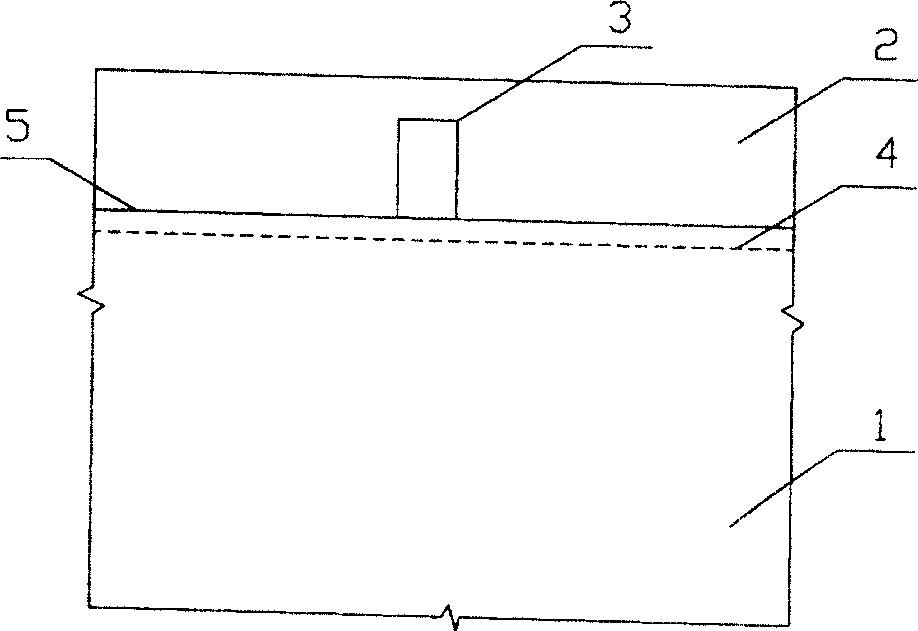

[0023] like figure 1 , figure 2 , image 3 As shown, a process of using FRP bars to strengthen the functionally graded material interface of the shield segment. The interface between the reinforced concrete structure layer 1 and the high impermeability protection layer 2 of the shield tunnel concrete segment is a functionally graded material interface. Including the following steps:

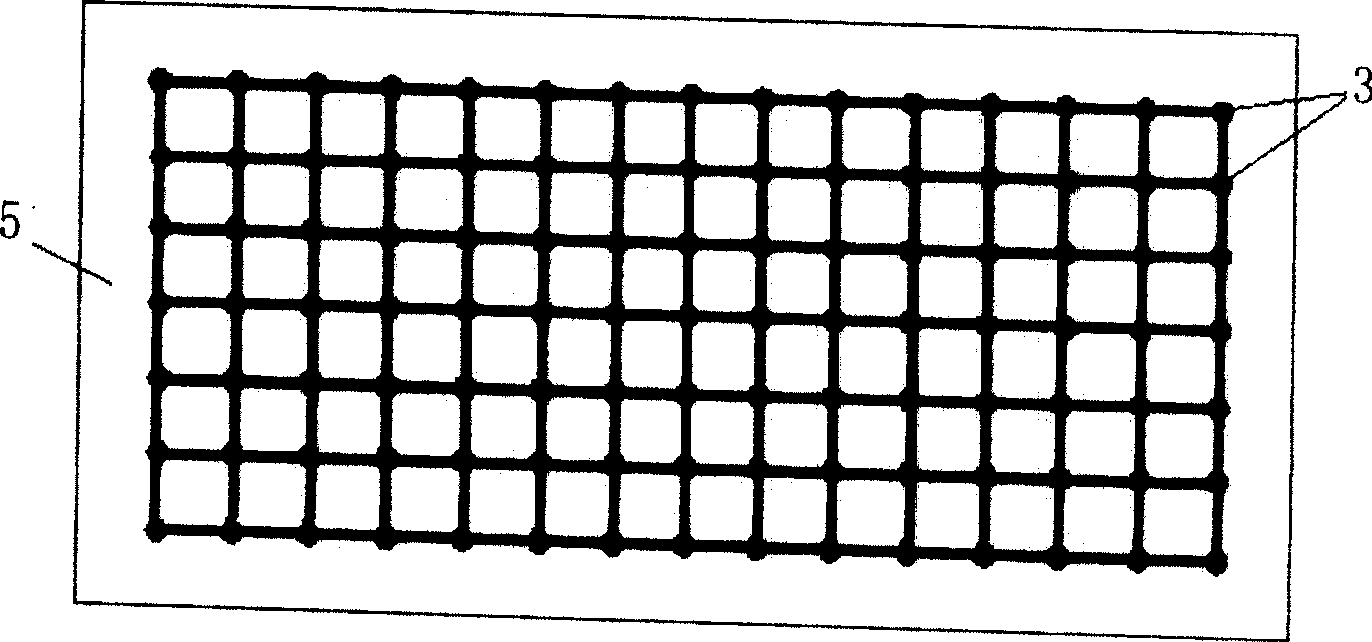

[0024] 1) Establish the FRP tendon anchoring and strengthening transition zone: FRP tendons 3 and flexible FRP mesh cloth 5 are combined to form the FRP tendon interface anchoring reinforcement material, and the preparation process of FRP tendons 3 and flexible FRP mesh cloth 5 is prefabricated in the factory and mass-produced , can be used directly in the preparation process of the shield segment, so as not to affect the construction progress; the outer surface of the FRP reinforcement is a threaded structure, with a diameter of 20mm and a length of 30mm. The spacing between adjacent FRP rib...

Embodiment 2

[0038] Such as figure 1 , figure 2 , image 3 Shown, a kind of technology that utilizes FRP rib to strengthen the functionally graded material interface of shield segment, it comprises the following steps:

[0039] 1) Establish the anchoring and strengthening transition zone of FRP tendons: the outer surface of FRP tendons is a threaded structure with a diameter of 10mm and a length of 20mm. The distribution of FRP tendons on the grid cloth is distributed in a lattice, and the distance between two adjacent FRP tendons is: 50mm.

[0040] Before the concrete is poured, the flexible FRP grid cloth 5 is laid and pasted on the steel cage surface 4 in the reinforced concrete segment steel mold, and the FRP bars 3 are distributed on the flexible FRP mesh cloth 5 in a lattice shape to form the FRP bar anchoring strengthening transition Area, in which FRP tendons 3 and FRP mesh cloth 5 are bonded together to form an integral structure, which is completed through factory prefabricat...

Embodiment 3

[0044] Such as figure 1 , figure 2 , image 3 Shown, a kind of technology that utilizes FRP rib to strengthen the functionally graded material interface of shield segment, it comprises the following steps:

[0045] 1) Establish the anchoring and strengthening transition zone of FRP tendons: the outer surface of FRP tendons is a threaded structure with a diameter of 30 mm and a length of 40 mm. The distribution of FRP tendons on the grid cloth is distributed in a lattice, and the distance between two adjacent FRP tendons is: 90mm.

[0046] Before the concrete is poured, the flexible FRP grid cloth 5 is laid and pasted on the steel cage surface 4 in the reinforced concrete segment steel mold, and the FRP bars 3 are distributed on the flexible FRP mesh cloth 5 in a lattice shape to form the FRP bar anchoring strengthening transition Area, in which FRP tendons 3 and FRP mesh cloth 5 are bonded to form an integral structure, which is completed through factory prefabrication; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com