Thread fixing structure of thermal-state magnesium alloy component

A fixed structure, magnesium alloy technology, applied in the direction of threaded fasteners, nuts, connecting components, etc., can solve the problems of bolt looseness, thread wear, fracture, etc., and achieve the effect of avoiding loose connection, ensuring firm connection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

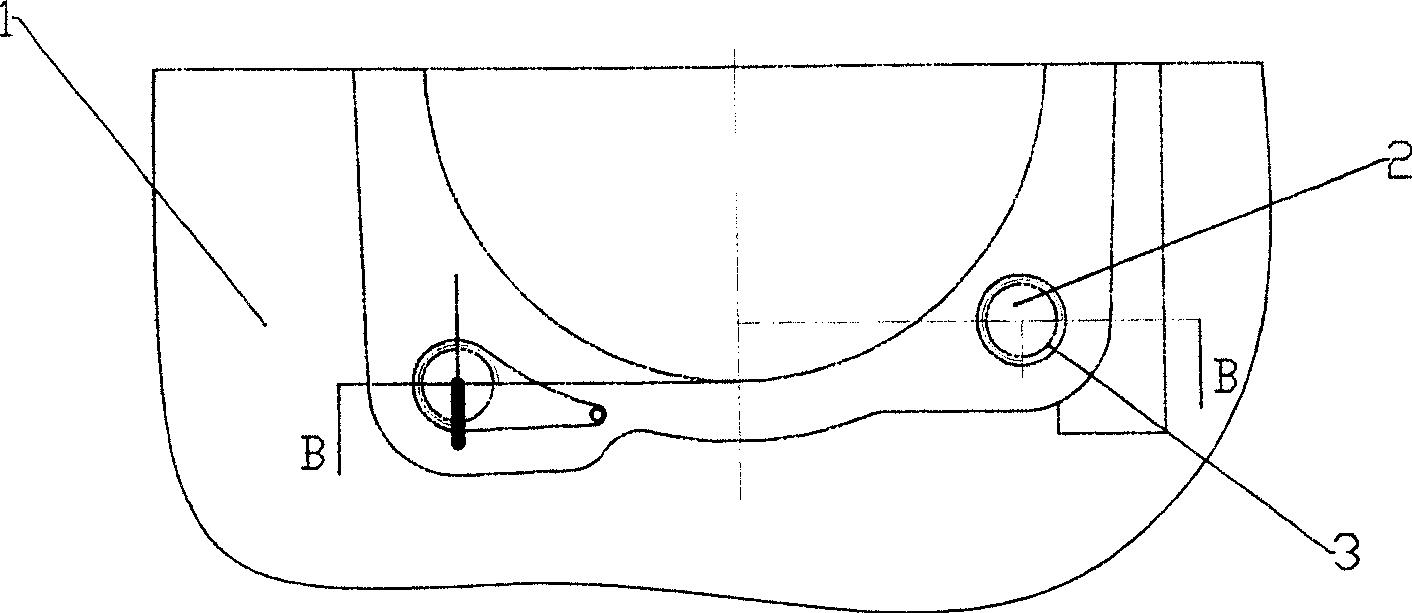

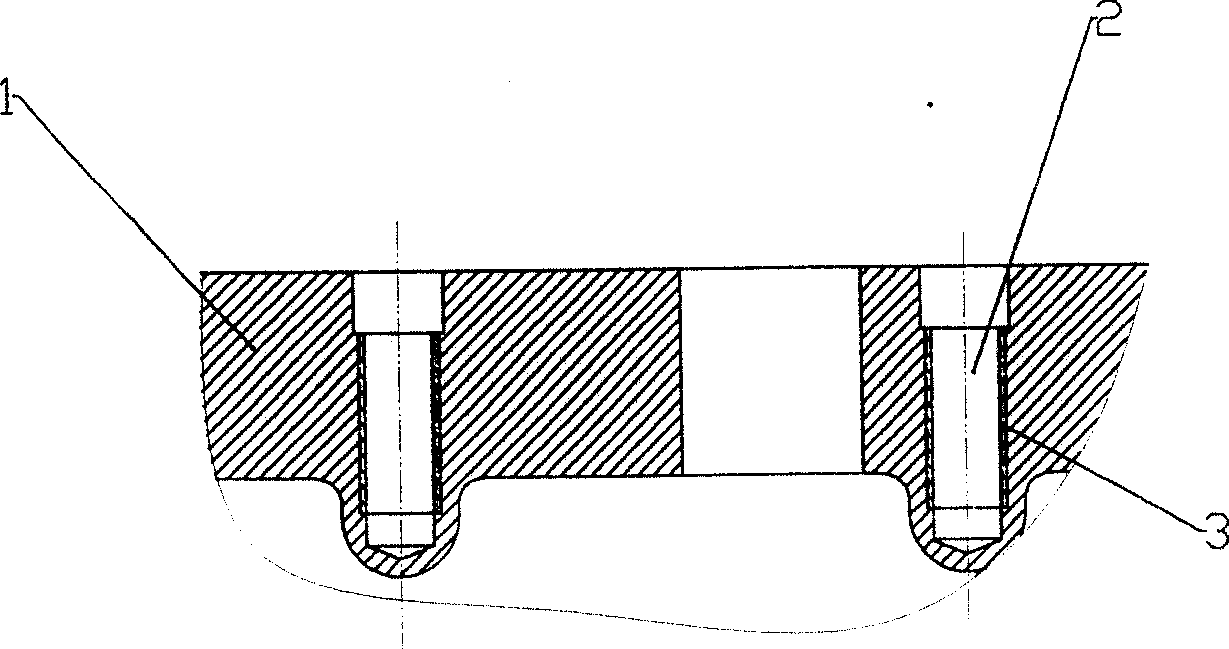

[0021] Such as figure 1 with figure 2 Shown is a right crankcase body 1, which is formed by die-casting of magnesium alloy material. At the joint surface of the cylinder mouth of the crankcase body, the parts for setting screw holes are respectively embedded with the joint surface perpendicular to the joint surface and facing into the box body. The extended hard insert 3 is machined into the hard insert 3 with a screw hole 2 perpendicular to the joint surface. The hard insert 3 is a steel sleeve, the outer wall of which is processed with external threads, and is embedded in the magnesium alloy right crankcase 1 through the external threads. This structure allows the insert 3 to be inserted into the magnesium alloy right crankcase 1 Loaded after the die-casting process is completed. More ideally, the thread of the external thread of the hard insert 3 is thicker than the thread of the internal thread of the screw hole 2, so as to enhance the strength of the thread on the magn...

Embodiment 2

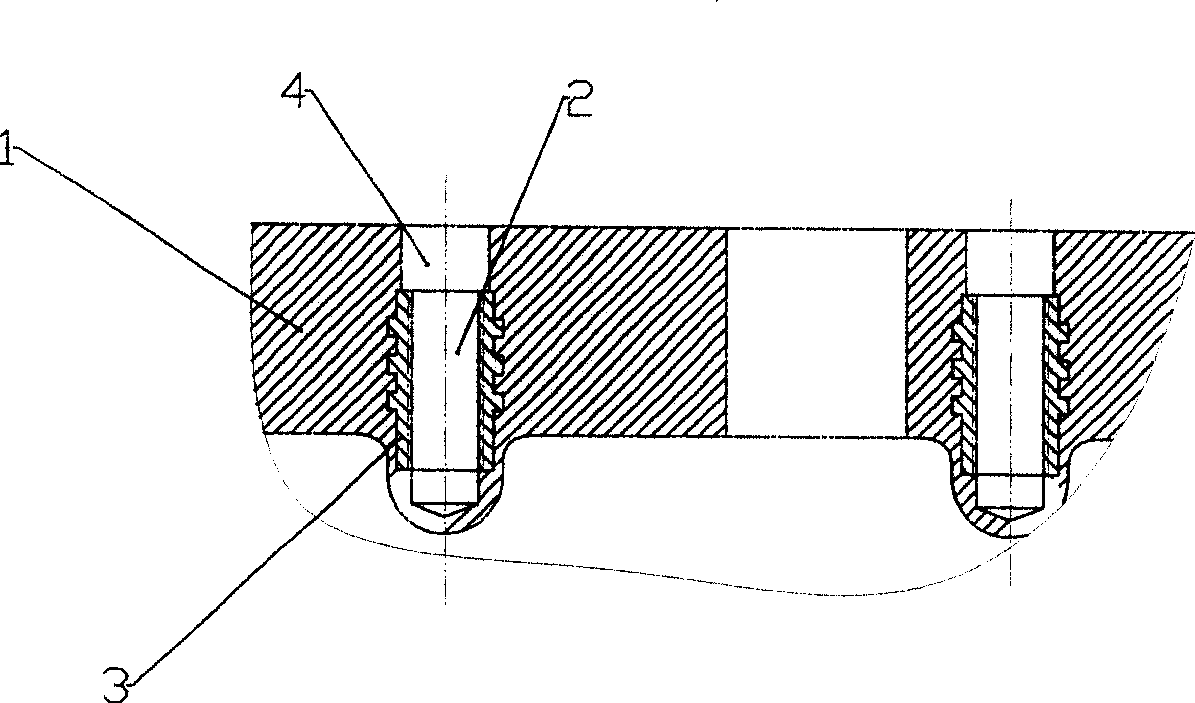

[0023] image 3 It is another embodiment of the screw fixing structure of the hot magnesium alloy parts of the present invention. The hard insert 3 made of hard materials such as cast iron or aluminum alloy, which is processed with internal threads, is die-cast on the magnesium alloy crankcase body 1. When forming, it is pre-embedded in the box body and molded integrally with the box body 1, so that the firmness of the combination of the hard insert 3 and the magnesium alloy crankcase body 1 is guaranteed.

[0024] In order to improve the solidity of the combination of the hard insert 3 and the hot magnesium alloy crankcase 1, the combination Figure 4 with Figure 5 As shown, a groove or a protrusion 31 structure can be set on the outer surface of the hard insert 3, and the groove or protrusion structure can be continuous in the circumferential direction of the hard insert 3, or can be as Figure 5 Interrupted grooves or protrusions 31, shown here, also prevent rotation of ...

Embodiment 3

[0027] The hard insert 3 is directly assembled with the magnesium alloy crankcase 1 through interference fit, and the hard insert 3 and the magnesium alloy parts are combined more firmly due to thermal expansion under hot working conditions.

[0028] Although the examples in this embodiment all take the crankcase of a motorcycle engine as an example, those skilled in the art can understand that the present invention is applicable to the screw fixing structure of magnesium alloy parts in various hot working states.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com