Method for repairing plasma display screen wire break electrode

A technology of a plasma display screen and a repair method, which is applied in the field of flat panel display, can solve the problems of difficult maintenance and cleaning of a feeding system, high fineness and high cost, and achieves the effects of simple and easy operation, uniform thickness and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

[0016] refer to figure 1 , first check the electrode through the inspection machine, find out the open circuit electrode that needs to be repaired, and record the X and Y coordinates of the open circuit 1.

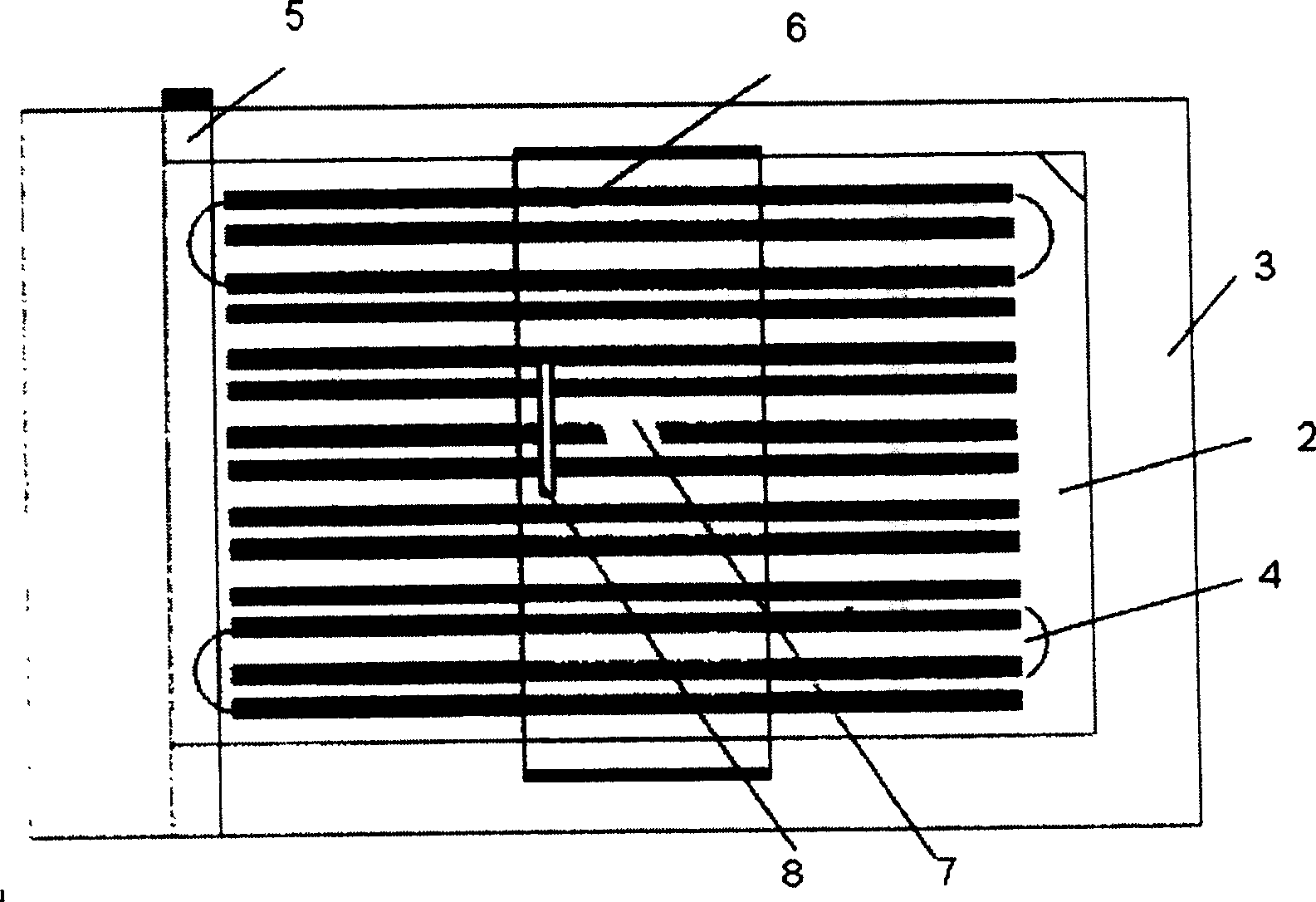

[0017] refer to figure 2 , 3 , 4. Place the glass substrate 2 that needs to be repaired by electrode disconnection on the table 3 that can be fixed or vacuum-adsorbed, and the rubber gasket 4 for placing the glass substrate 2 is installed on the table 3, and the glass is fixed by the slot 5. The substrate 2 is fixed to ensure the fixed position of the glass substrate 2, which is more convenient to operate. Move the support with the stencil 6 into the table top 3, adjust the support so that the two sides of the stencil 6 are respectively parallel to the two sides of the glass substrate 2, and the length of the screen used for printing on the stencil 6 is preferably grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com