Method for producing product decomposed with subcritical water and apparatus for decomposition treatment with subcritical water

A subcritical water and decomposition treatment technology, which is applied in the direction of using atmospheric pressure to chemically change substances, chemical/physical/physicochemical processes, oxidation treatment of sludge, etc., can solve problems such as difficult to control the decomposition of organic waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

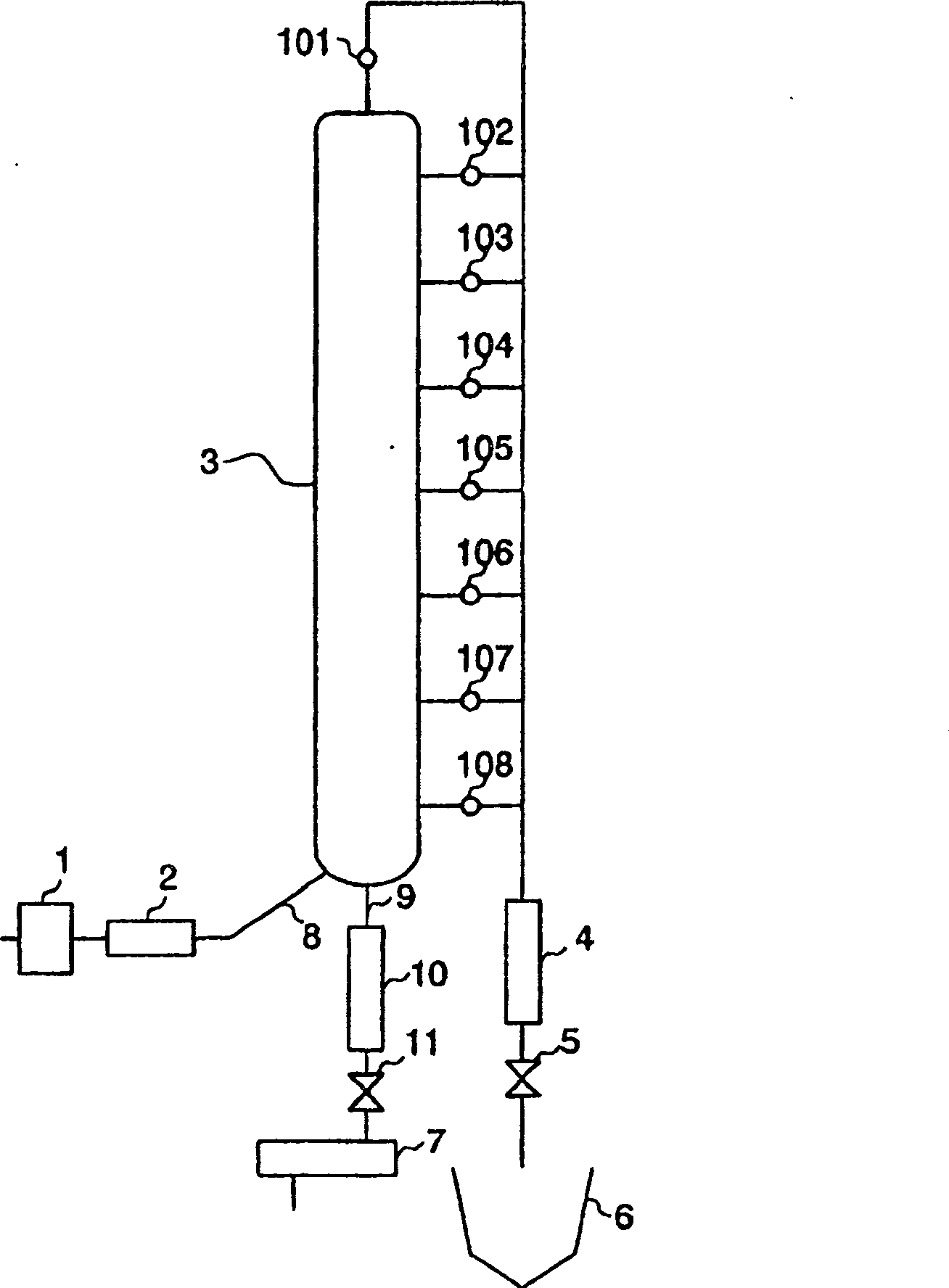

[0093] figure 1 It is a conceptual configuration diagram showing an example of the reaction apparatus according to Embodiment 1 of the present invention. As shown in the figure, this apparatus includes a reaction container 3 , a pressurizing device 1 , a heating device 2 , a cooling pipe 4 , a back pressure valve 5 , a reaction finished product recovery tank 6 , and an exhaust product recovery tank 7 . figure 1 In the device, the heating device 1 is also the mixture introducing device. The reaction vessel 3 is vertical and cylindrical, and is basically installed vertically. An introduction port 8 and a discharge port 9 are provided at the bottom of the reaction vessel 3 . The pressurizing device 1 and the heating device 2 are connected to the introduction port 8 through pipes. In addition, the effluent recovery tank 7 is connected to the discharge port 9 via a cooling pipe and a back pressure valve 11 . An outlet is provided on the head and side walls of the reaction vesse...

Embodiment approach 2

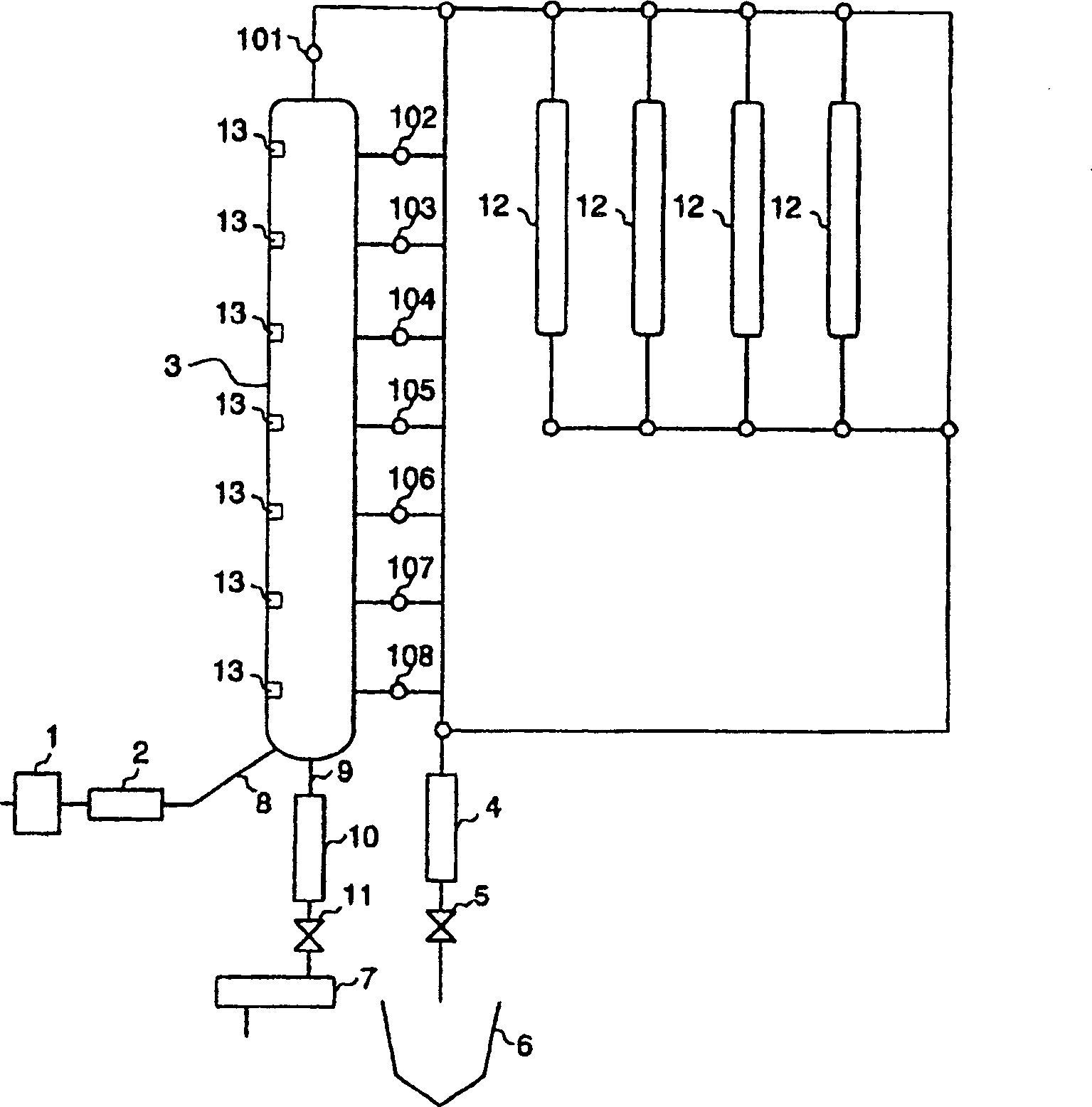

[0127] Embodiment 2 is an embodiment in which a secondary reaction container is further installed on the reaction apparatus of Embodiment 1. figure 2 It is a schematic configuration diagram illustrating another example of the subcritical water splitting treatment device of the present invention. figure 2 in, with figure 1 The same symbol on the same part. like figure 2 As shown, the secondary reaction container 12 is connected to the outlet 101 of the reaction container 3 via a tube. The secondary reaction containers 12 are respectively connected by tubes. A switching valve is provided on each pipe. The secondary reaction container 12 can be freely switched between series connection and parallel connection by switching the valve. These secondary reaction containers 12 are connected to the cooling pipe through pipes, and further connected to the back pressure valve 5 . In front of the back pressure valve 5, a reaction finished product recovery tank 6 is provided. In t...

Embodiment approach 3

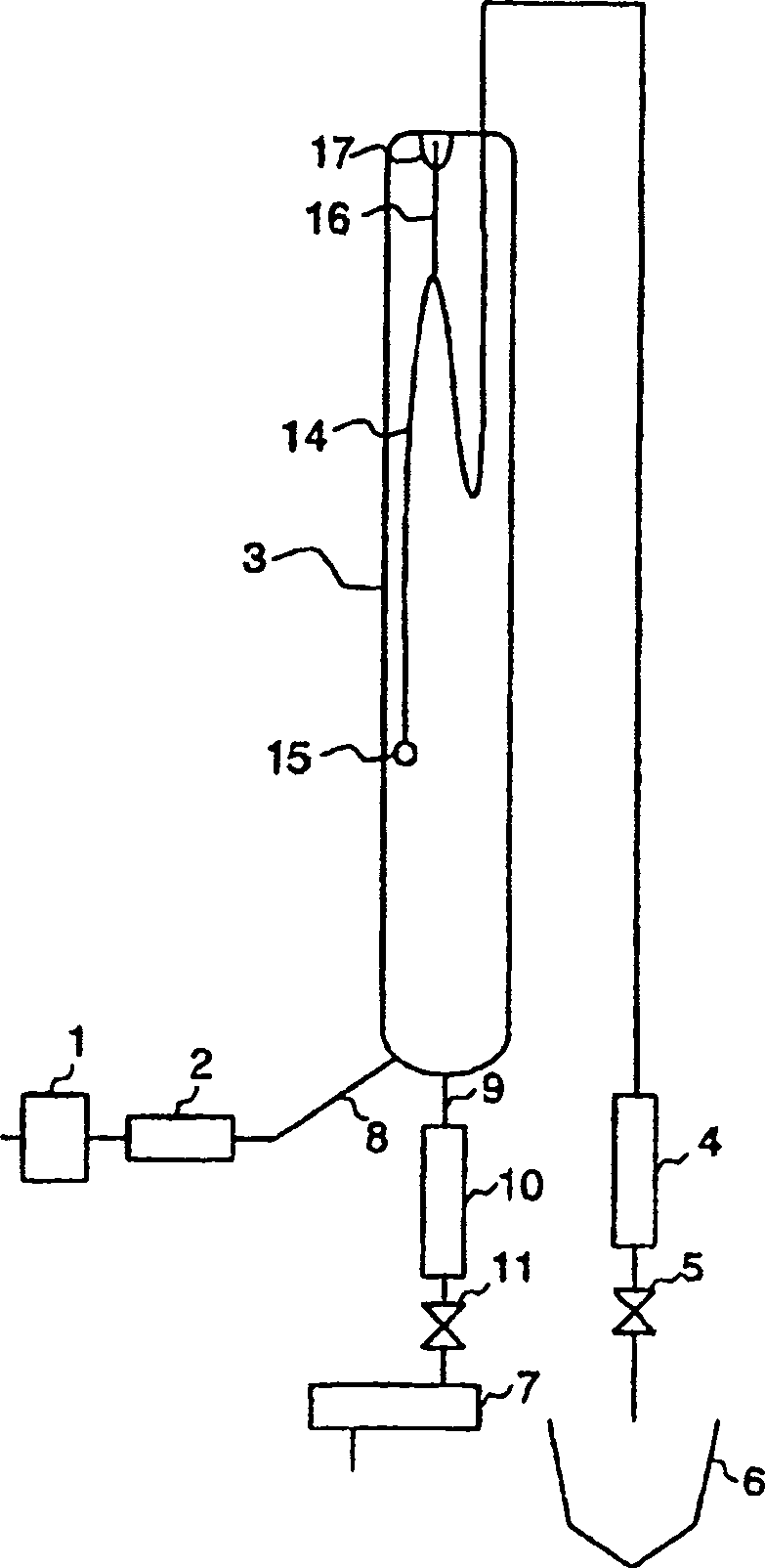

[0138] image 3 It is a schematic configuration diagram illustrating another example of the subcritical water splitting treatment device of the present invention. image 3 in, with figure 1 The same parts have the same symbol. like image 3 As shown, in the apparatus of this embodiment, there is provided an outlet that can move continuously along the flow direction of the subcritical water in the reaction vessel 3 .

[0139] The movable outlet is composed of a flexible tube 14, a suction part 15 positioned at its front end to inhale the required subcritical water soluble layer, a chain 16 for lifting the above-mentioned flexible tube 14, and a groove that can roll up or put down the chain 16 Internal gear 17 constitutes. The suction part 15 can be fixed at a desired position by adjusting the length of the chain 16 .

[0140] In the example shown in the figure, the flexible tube 14 is inserted from the upper end of the reaction vessel 3 , but may be inserted from the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com