Etchant composition for copper/molybdenum film or copper/molybdenum alloy film

A technology of composition and molybdenum alloy, which is applied in the field of etching liquid composition, can solve the problems of low metal content, large amount of etching liquid, loss of etching cone angle, etching deviation and etching straightness, etc., so as to increase the etching capacity , increase the number of repetitions, reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0020] According to another embodiment of the present invention, in addition to the etching inhibitor, the etchant composition further includes a glass etching inhibitor, which can slow down the etching speed of the glass substrate as the lower film to the greatest extent. Preferably, the glass etching inhibitor is a compound containing both boron atoms and fluorine atoms; more preferably, the glass etching inhibitor is boric acid or boric acid salt, and is further preferably selected from the group consisting of fluoroboric acid (HBF 4 ), sodium fluoroborate (NaBF 4 ), potassium fluoroborate (KBF 4 ), ammonium fluoroborate (NH 4 BF 4 ) and mixtures thereof.

[0021] Preferably, the glass etch inhibitor is present in an amount of 0.01 to 2% by weight, more preferably in an amount of 0.05 to 1% by weight. If it is less than 0.01% by weight, the effect of inhibiting glass etching is very small, and if it exceeds 2% by weight, the etching speed will be slowed down and the eng...

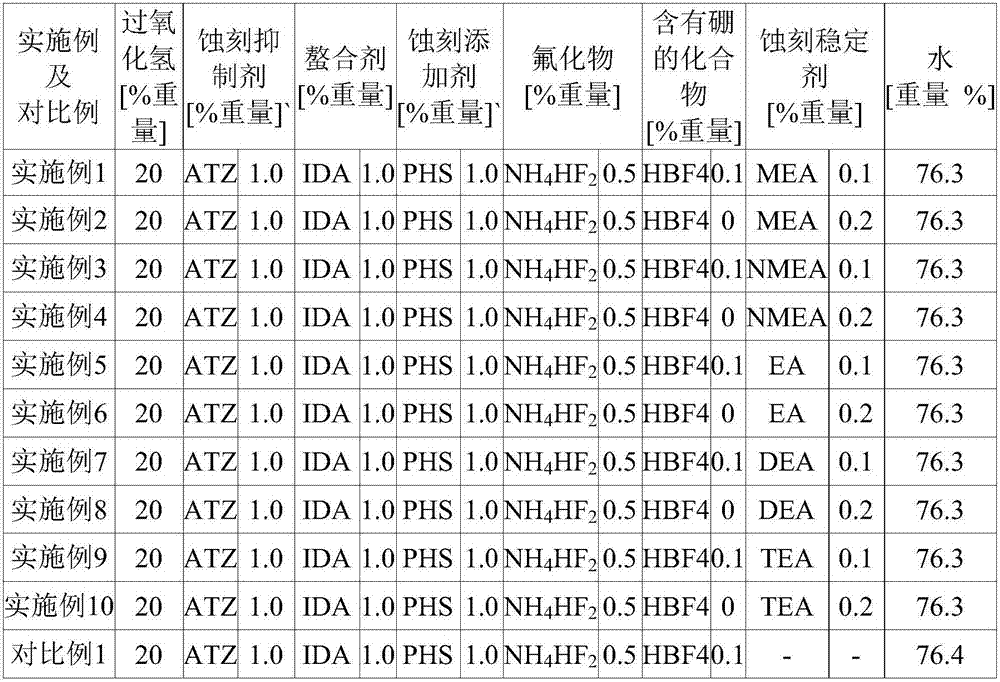

Embodiment 1 to 10 and comparative example 1

[0037] The contents of the components listed in Table 1 below were mixed to prepare the compositions of Examples 1 to 10 and Comparative Example 1 of the present invention.

[0038] Table 1

[0039]

[0040] ATZ: 5-aminotetrazole (5-aminotetrazole),

[0041] IDA: iminodiacetic acid (iminodiacetic acid),

[0042] PHS: Potassium hydrogen sulfate

[0043] MEA: monomethanolamine

[0044] NMEA: N-methylethanolamine (N-methylethanolamine)

[0045] EA: Ethanolamine

[0046] DEA: Diethanolamine

[0047] TEA: Triethanolamine

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com