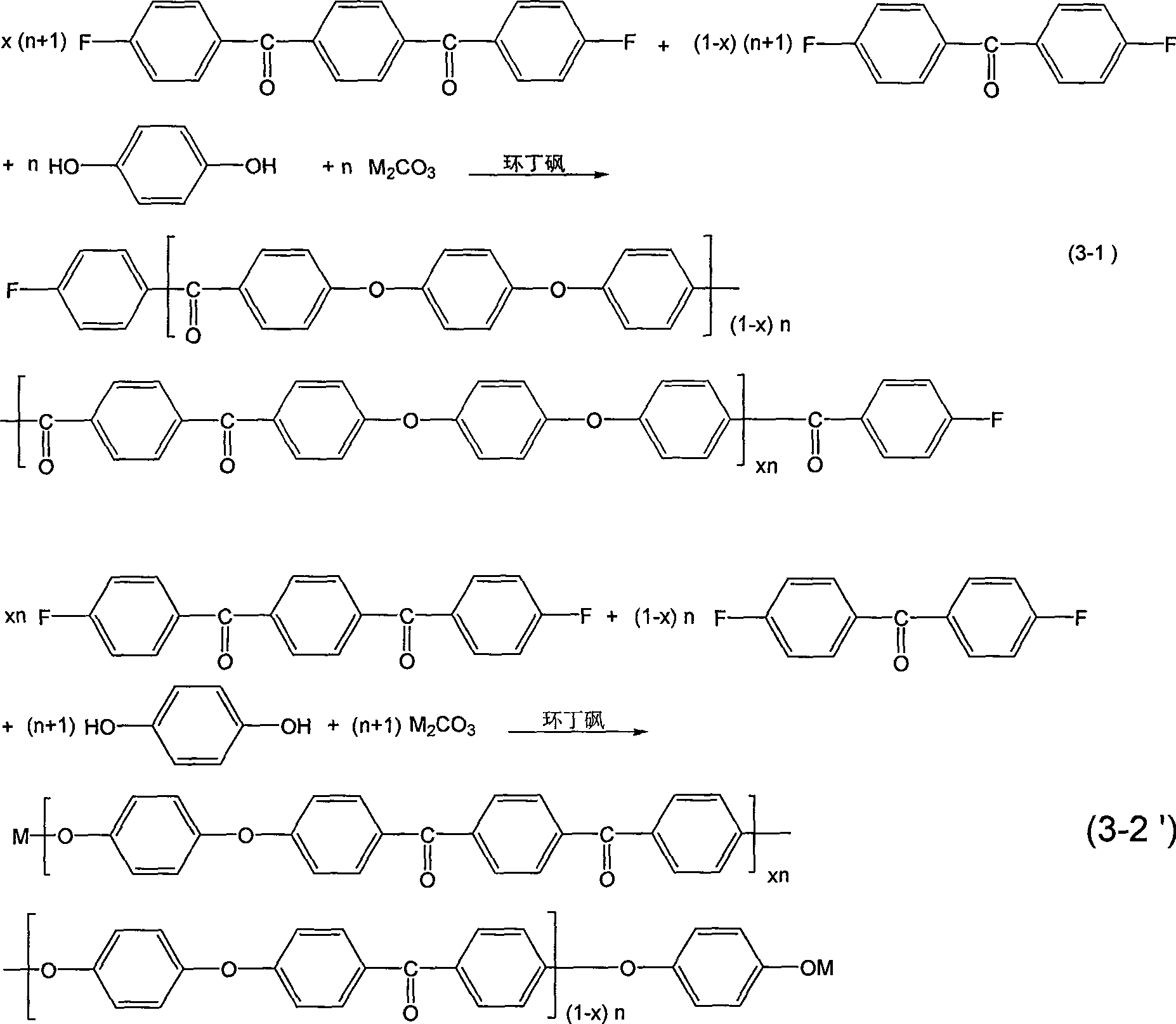

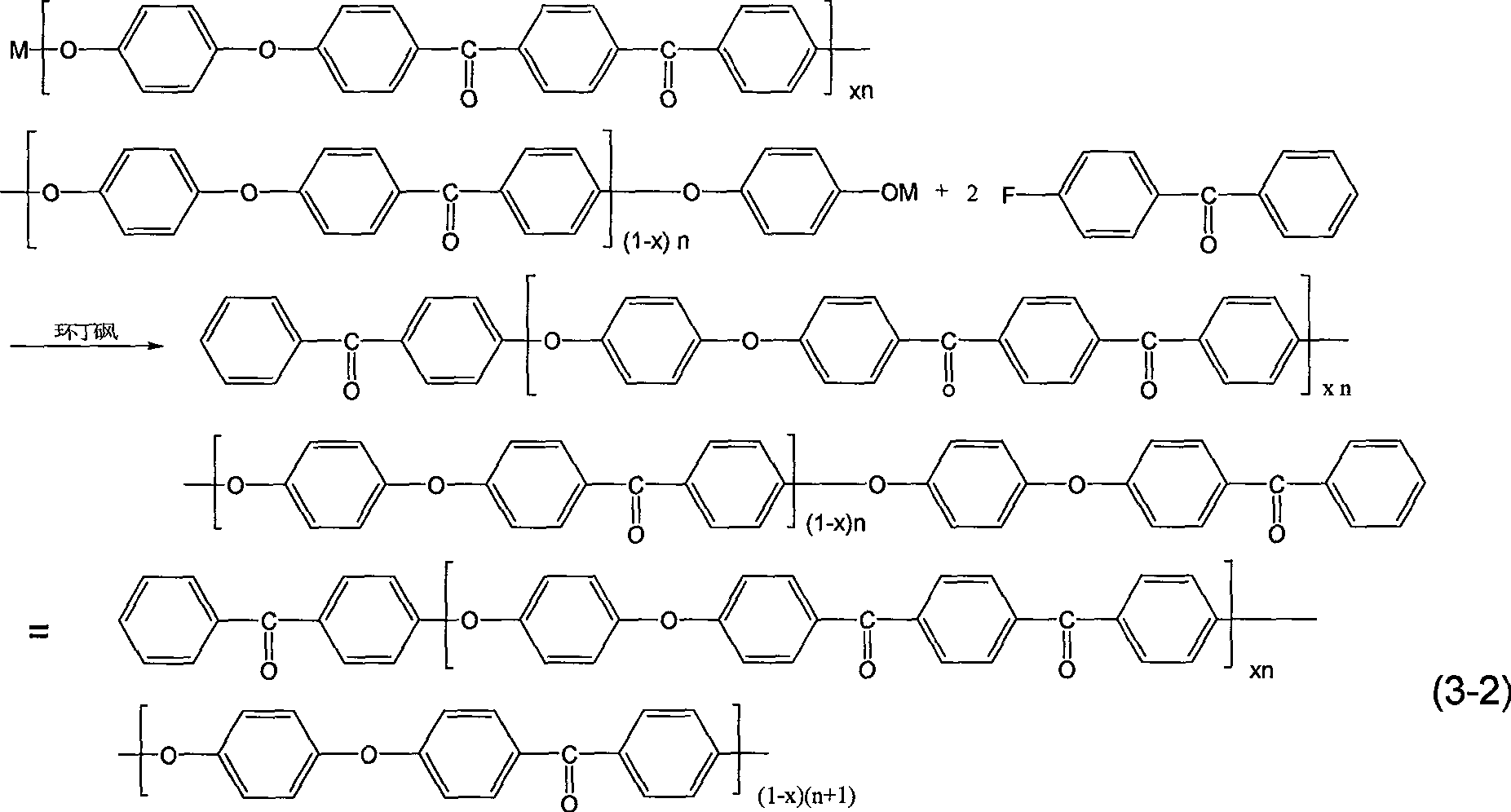

Synthesis method of ternary copolymer containing PEEK and poly(ether ether ketone ketone)s using sulfolane as solvent

A technology of polyether ether ketone ketone terpolymer and fluorine-terminated polyether ether ketone, which is applied in the field of polymer materials and can solve the problems of unsafe hidden danger, high consumption, increased production cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] First add 490g of refined sulfolane to a three-necked reaction flask equipped with a thermometer, nitrogen pipe, condensing water separator, and stirrer, and then add 0.98g (0.00303mol) of 4,4'-difluorotriphenyldione in sequence 65.45g (0.29997mol) 4,4'-difluorobenzophenone 33.03g (0.30mol) hydroquinone 87.48 g of polymer can be obtained, with a solid content of 15.15%. After adding 74g xylene (15% of solvent) again, stir, heat (reaction flask is put into corresponding electric heating mantle), treat that it all dissolves and when temperature rises to 80 ℃, add 25.73g (0.153mol, excess 2 %)K 2 CO 3 and 16.2g (0.153mol, excess 2%) Na 2 CO 3 , and then continue to heat up, when the temperature rises to 150 ° C, the system starts to azeotrope, xylene and water condense in the water separator, the upper layer of xylene refluxes, and the lower layer of water is continuously released. When the water is recovered to the theoretical amount, the upper layer of xylene St...

Embodiment 2

[0022] Change the batching ratio of Example 1, after adding 490g sulfolane sequentially, add 19.53g (0.0606mol) 4,4'-difluorotriphenyldione, 52.89g (0.2424mol) 4,4'-difluorodiphenyl Ketone, 33.03g (0.30mol) hydroquinone, the subsequent charging amount, charging sequence and reaction conditions and aftertreatment refining are completely the same as embodiment 1, then obtain the fluorine of x=0.2 as shown in (3-1) formula Terminated polyether ether ketone and polyetherether ketone ketone terpolymer, measured by DSC:

[0023] Tg=148℃

[0024] Tm=340℃

Embodiment 3

[0026] Change the batching ratio of Example 1, after adding 490g sulfolane in sequence, add 39.05g (0.1212mol) 4,4'-difluorotriphenyldione, 39.67g (0.1818mol) 4,4'-difluorodiphenyl Ketone, 33.03g (0.30mol) hydroquinone, the amount of addition, order of addition and reaction conditions and post-treatment refining thereafter are completely the same as embodiment 1, then obtain the fluorine of x=0.4 as shown in (3-1) formula Terminated polyether ether ketone and polyetherether ketone ketone terpolymer, measured by DSC:

[0027] Tg=152℃

[0028] Tm = 347°C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com