Method for prolonging retention period of molten steel in RH vacuum groove

A technology of residence time and vacuum tank, applied in the field of metallurgy, can solve the problems of short residence time and long processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

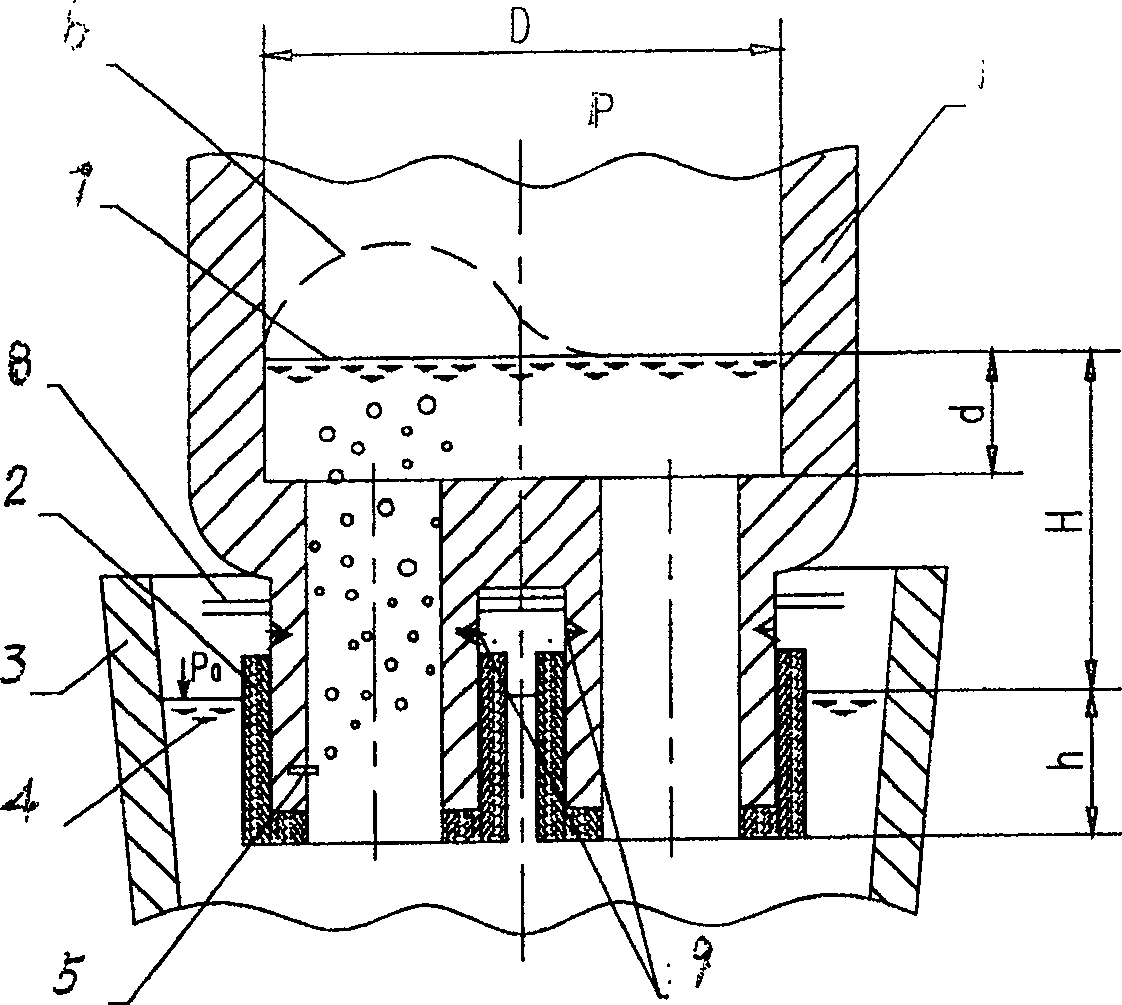

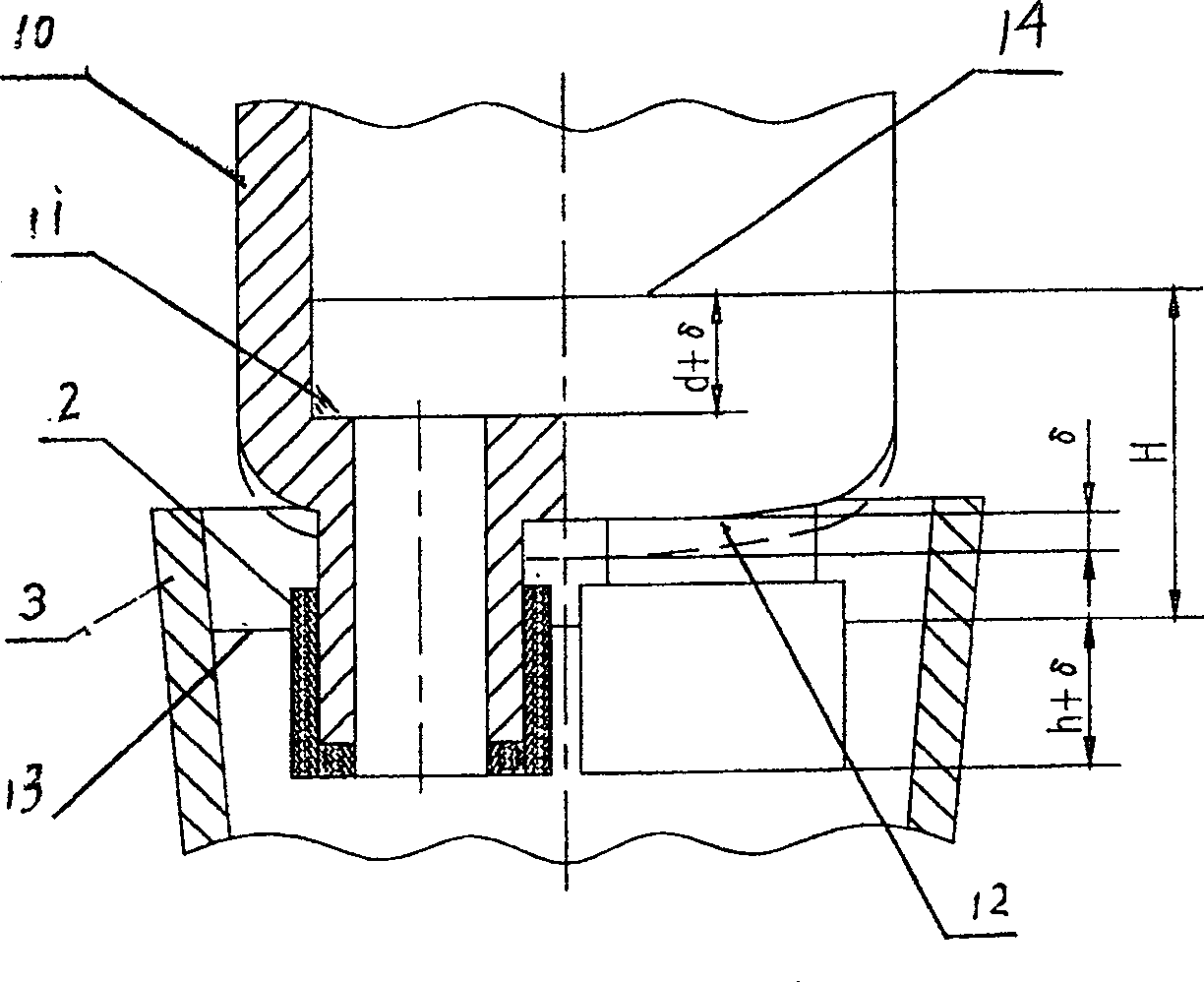

[0022] Embodiment of the present invention sees attached figure 2 :

[0023] Vacuum tank, the upper part of the vacuum tank 10 is vacuum, the bottom is equipped with a dipping tube 2, and the outside of the dipping tube 2 has an unshaped refractory material, which is inserted into the molten steel in the ladle 3, wherein: the bottom of the vacuum tank 1 is planar Shallow round bottom platform 12, the inside of this shallow round bottom platform 12 has reinforcing ribs 11.

[0024] There are two dipping tubes with different opening heights in the vacuum tank, the one with the lower opening is the ascending tube, and the one with the higher opening is the descending tube.

[0025] The material at the bottom of the vacuum tank is 16Mn.

[0026] attached by figure 2 It can be seen that after changing from a spherical bottom to a shallow circular table bottom, the bottom of the vacuum tank is thinned by δ (about 100 mm). In this way, when the radiation protection plate, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com