Prestressing system device of concrete structure and uses of the device

A concrete structure and prestressing technology, applied in the field of prestressing systems, can solve the problems of accelerated corrosion, insufficient grouting, inability to replace prestressed tendons and detect stress, etc., to achieve improved corrosion resistance, low cost, easy maintenance and Monitoring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Accompanying drawing is embodiment of the present invention

[0023] Below in conjunction with accompanying drawing, content of the present invention will be further described:

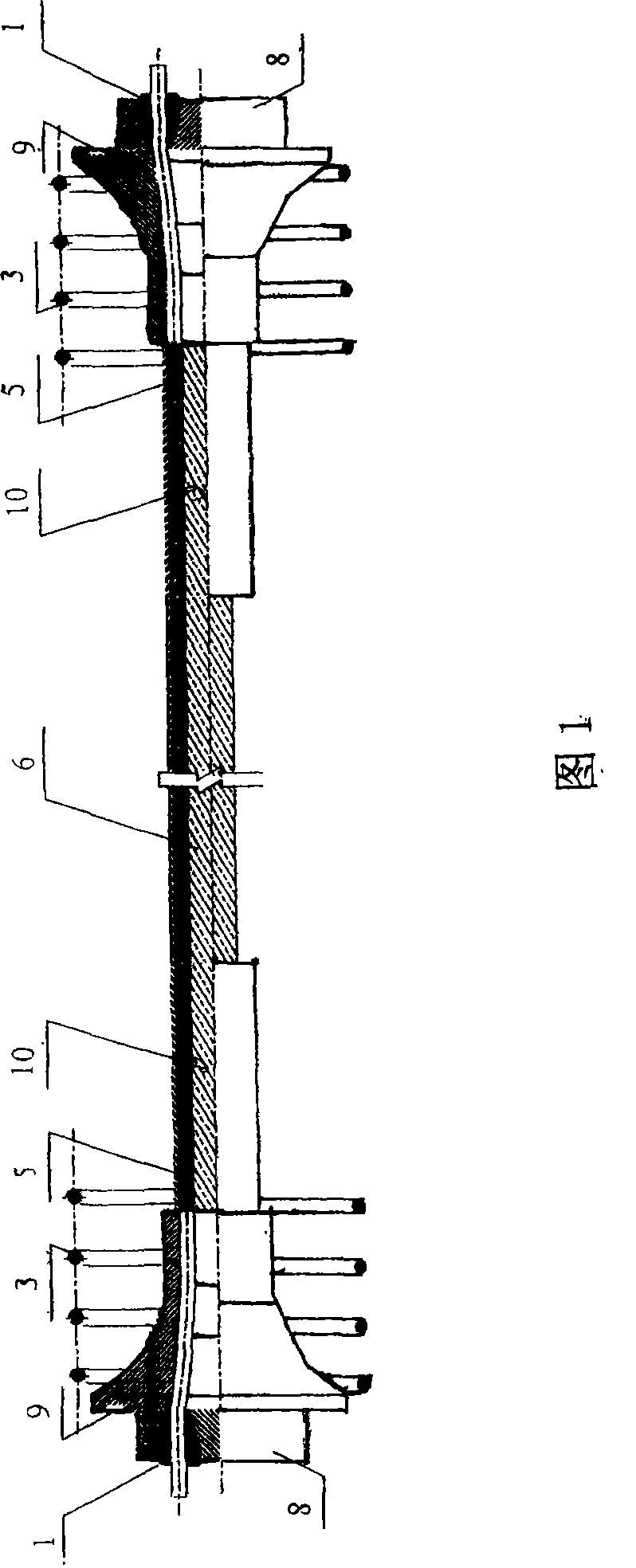

[0024] Referring to Figure 1, the two ends of the steel strand are fixedly connected to the anchor head, one end of the anchor head is connected to the anchor backing plate, the anchor backing plate is connected to the spiral reinforcement and the grouting hole 9, and the other end of the anchor backing plate is connected to the forming pipe. The inner cavity of the forming pipe is poured with cement slurry 10 through the grouting hole.

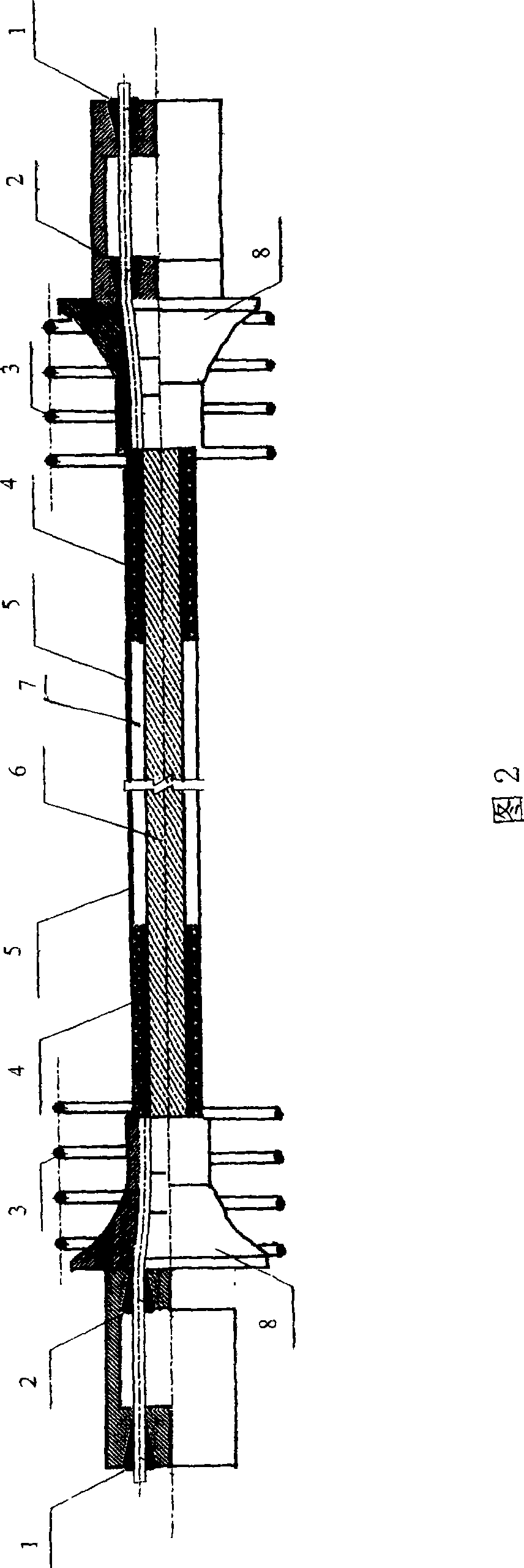

[0025] As shown in Figure 2, the two ends of the steel strand 6 are fixedly connected to the first-level anchor head 1, the anchor plate 8 is connected to the spiral rib 3, and the second-level anchor head 2 is also connected in series behind the anchor head 1. One end of the secondary anchoring anchor head 2 is connected to the anchor plate 8, the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com