Efficient anaerobic ammoxidation reactor

A technology of anaerobic ammonium oxidation and reactor, which is applied in the field of high-efficiency anaerobic ammonium oxidation reactor, can solve the problems that are not conducive to the separation of sludge and water from sedimentation performance granular sludge, will destroy the structure of activated sludge, and have high nitrogen content in effluent. Achieve the effect of large reaction potential, compact structure and uniform water distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

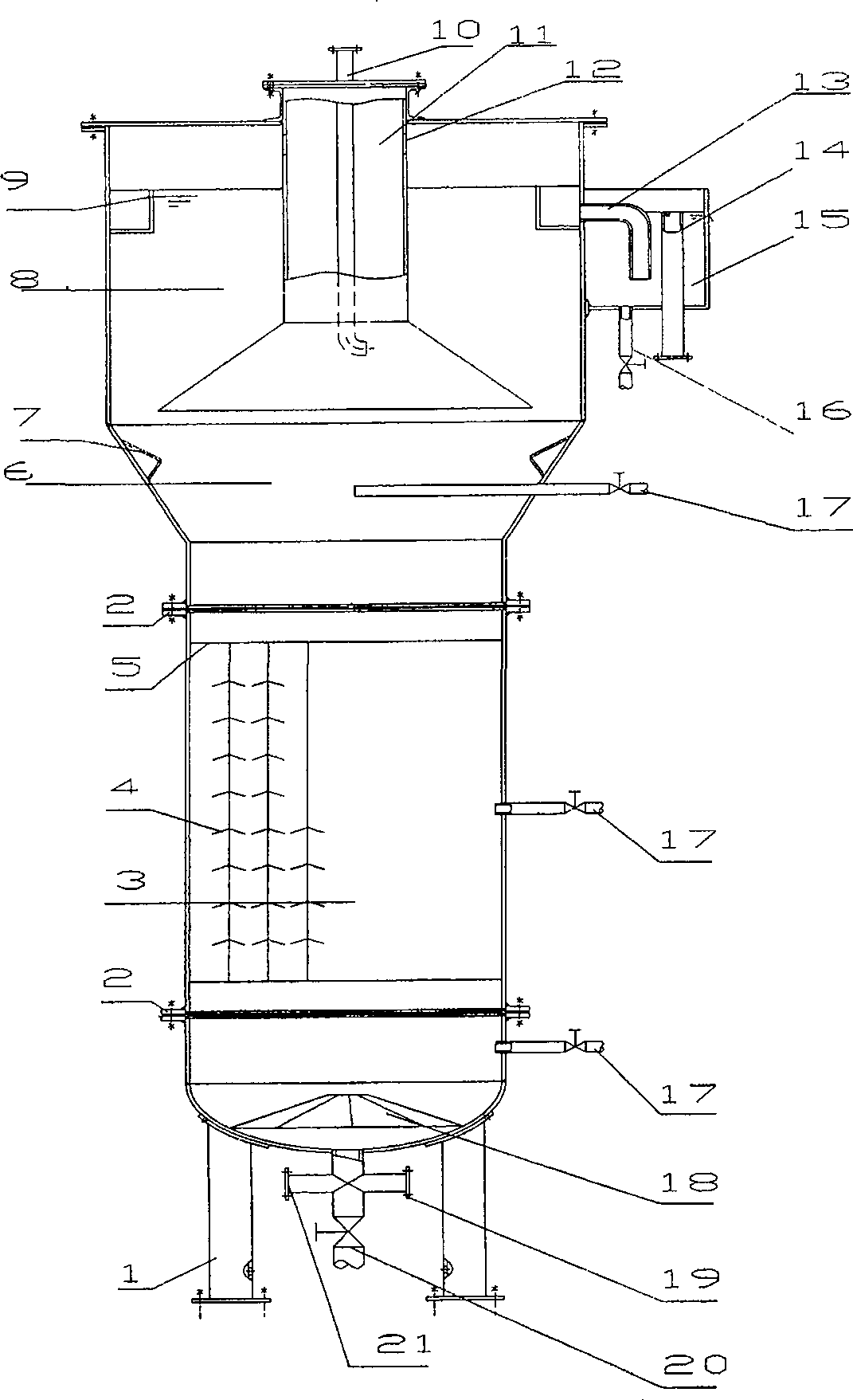

[0018] As shown in the drawings, the high-efficiency anaerobic ammonium oxidation reactor has a reactor body and a foot 1. The reactor body is sequentially provided with a sludge sedimentation chamber 8, a gradual expansion chamber 6, and an upflow reaction chamber 3 from top to bottom. The inner side of the bottom of the reactor body is provided with a swirl water distributor 18, and the outer side of the bottom of the reactor body is provided with a water inlet pipe 19, a mud discharge pipe 20, and a four-way pipe composed of an outer circulation pipe inlet 21. Cross-shaped grid 5, packing 4 is arranged between the upper and lower cross-shaped grids 5, the upper part of the gradual expansion chamber 6 is provided with an overflow conical baffle 7, the sludge settling chamber 8 is provided with a three-phase separator 11, and the sewage The upper side wall of the mud settling chamber 8 is provided with an overflow weir 9, an overflow weir outlet pipe 13, and a liquid seal tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com