Three dimensional knitting method of variable cross section preshaped product and its product

A three-dimensional weaving and pre-forming technology, applied in the field of three-dimensional weaving, can solve the problems of reinforced structure and composite material performance decline, increase the manufacturing cost of pre-formed parts, destroy the integrity of pre-formed parts, etc. Quality and performance, the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

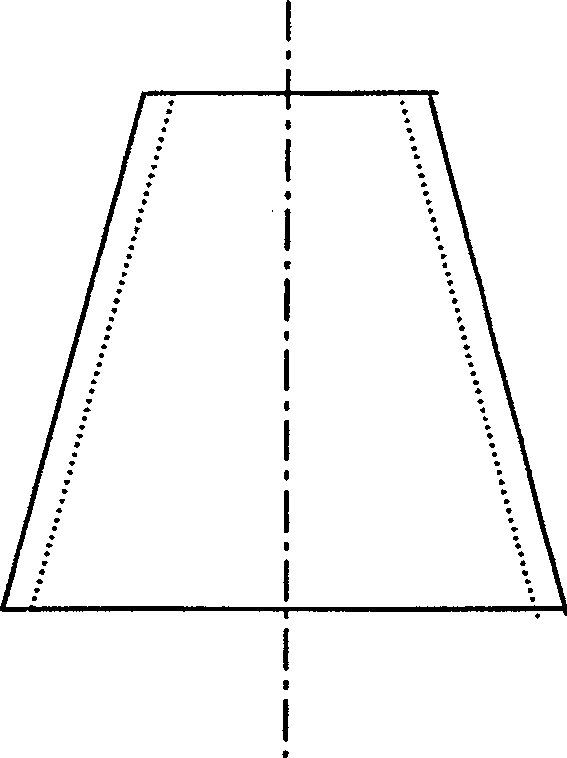

[0038] Adopt the method of the present invention to weave taper sleeve parts (referring to figure 1 ). The inner diameter of the large end is 400mm, the inner diameter of the small end is 100mm, height 700mm, wall thickness 20mm. The diameter cross section of the large end of the tapered sleeve is used as the reference section to start weaving, and the circular braiding method is used for weaving, and the weaving forming direction is along the height direction of the tapered sleeve body. The continuous change of the cross-sectional size of the tapered sleeve body can be approximated by designing the number of yarn reductions and the number of yarn reductions each time along the height direction of the tapered sleeve body according to the principle of uniform fiber volume content. Three-dimensional five-way weaving structure is adopted, the weaving yarn is T700-12k carbon fiber, the weaving angle is 25°, and the fiber volume content is 50%. The number of yarns required fo...

Embodiment 2

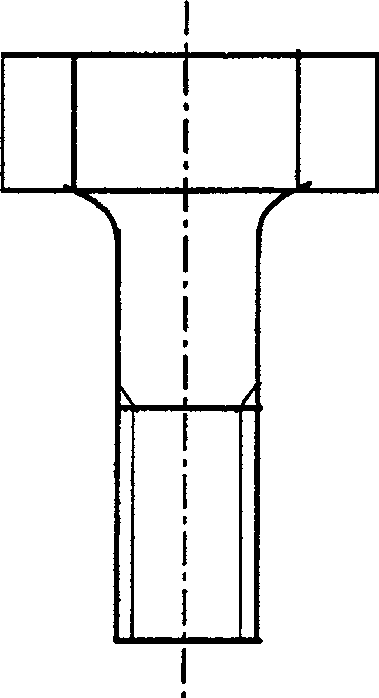

[0040] Adopt the screw product of the inventive method braiding M16 (referring to figure 2 ). The cross-section of the nut is used as the reference section for weaving, and the circular weaving method is adopted. The weaving structure is a three-dimensional five-directional weaving structure. The weaving yarn is T700-12k carbon fiber, the braiding angle is 20°, the fiber volume content is 50%, and the number of yarns used for weaving is 520. Normal weaving until the cross-sectional size suddenly changes from the nut to the screw, that is, at the joint between the nut and the screw, according to the size requirements before and after the cross-section change, after reducing 230 yarns at a time, the normal weaving of the screw ends.

Embodiment 3

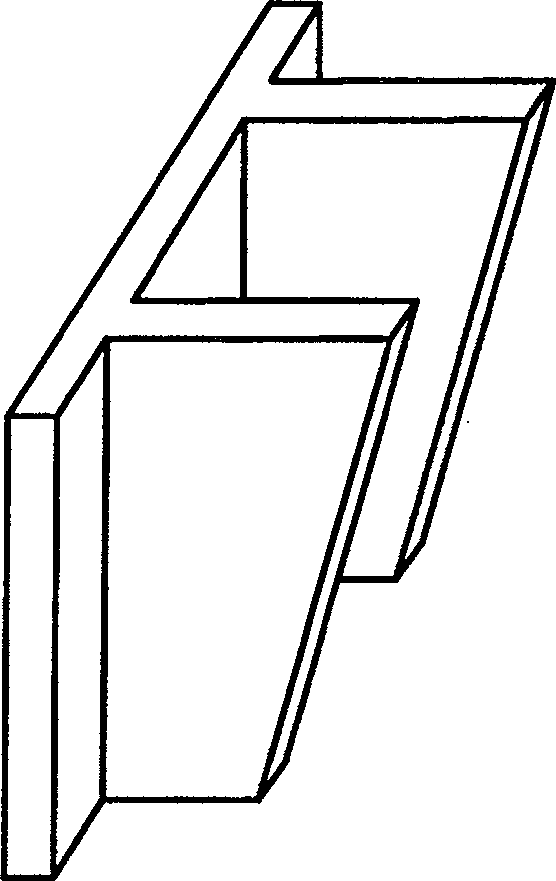

[0042] Adopt the inventive method to weave variable section square beam parts (referring to Figure 4 ). The big end of the square beam is used as the datum cross-section for the weaving start. The weaving forming direction is the length direction, and the cross-section change is approximated by multiple yarn reductions. The large-end braided yarn of the square beam is 12,000 pieces of 2400tex high-strength glass fiber, which are arranged in a rectangle on the machine chassis; the square weaving method is adopted, the weaving structure is three-dimensional six-way, the weaving angle is 30°, and the fiber volume content is 55 %; The section change is approximated by 5 times of yarn reduction, 600 yarns are reduced each time, and 150 yarn reduction points are evenly distributed on each yarn reduction section. When braided to the small end of the square beam, the section is 9000 pieces of 2400tex high-strength glass fiber yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com