Self-heat-supply energy-saving environmental protection incinerator

An energy-saving, environment-friendly, self-heating technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of short residence time of harmful substances, insufficient combustion, and inability to make gases harmless, so as to reduce labor costs The process of pushing garbage, prolonging the burning time, and the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the description:

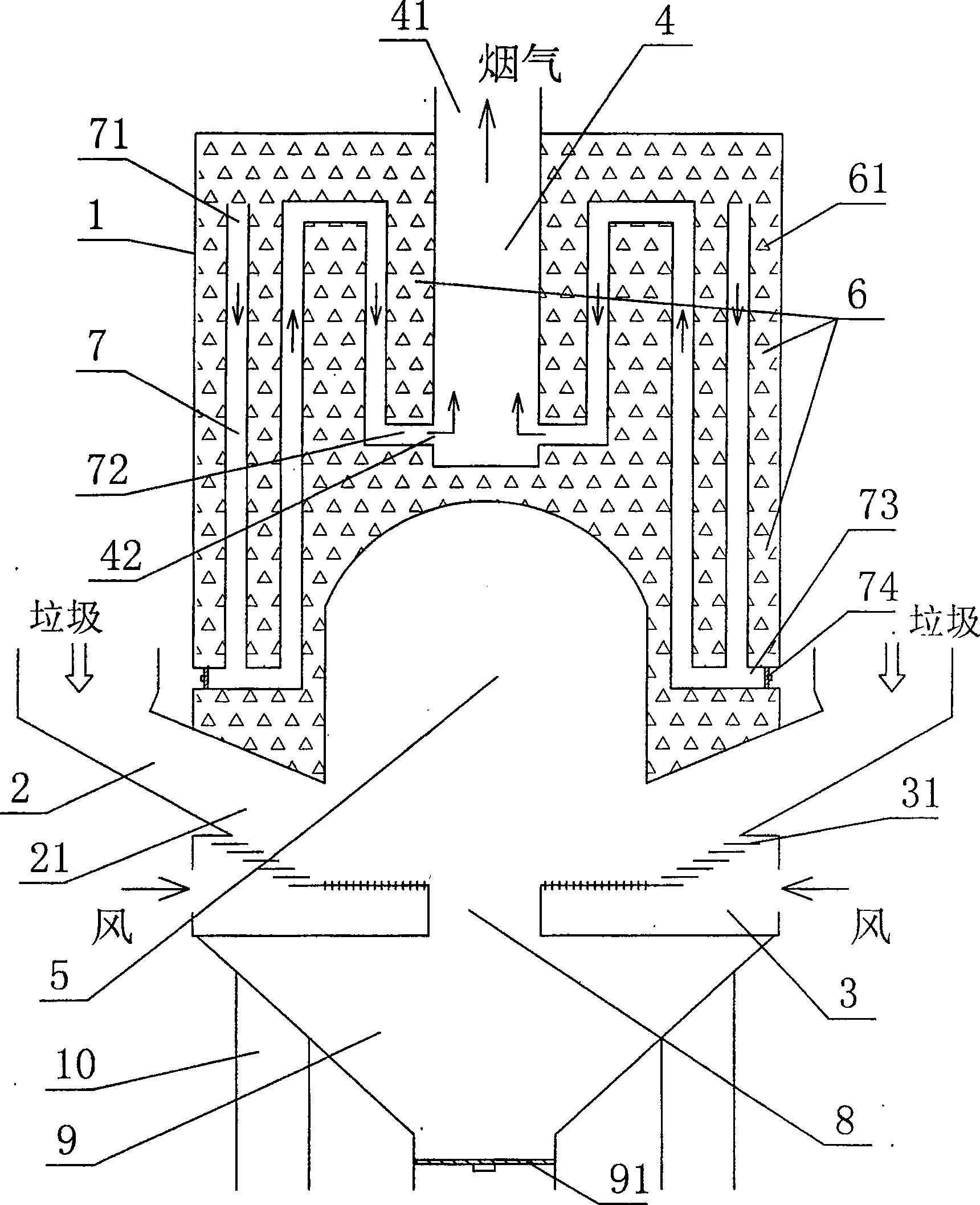

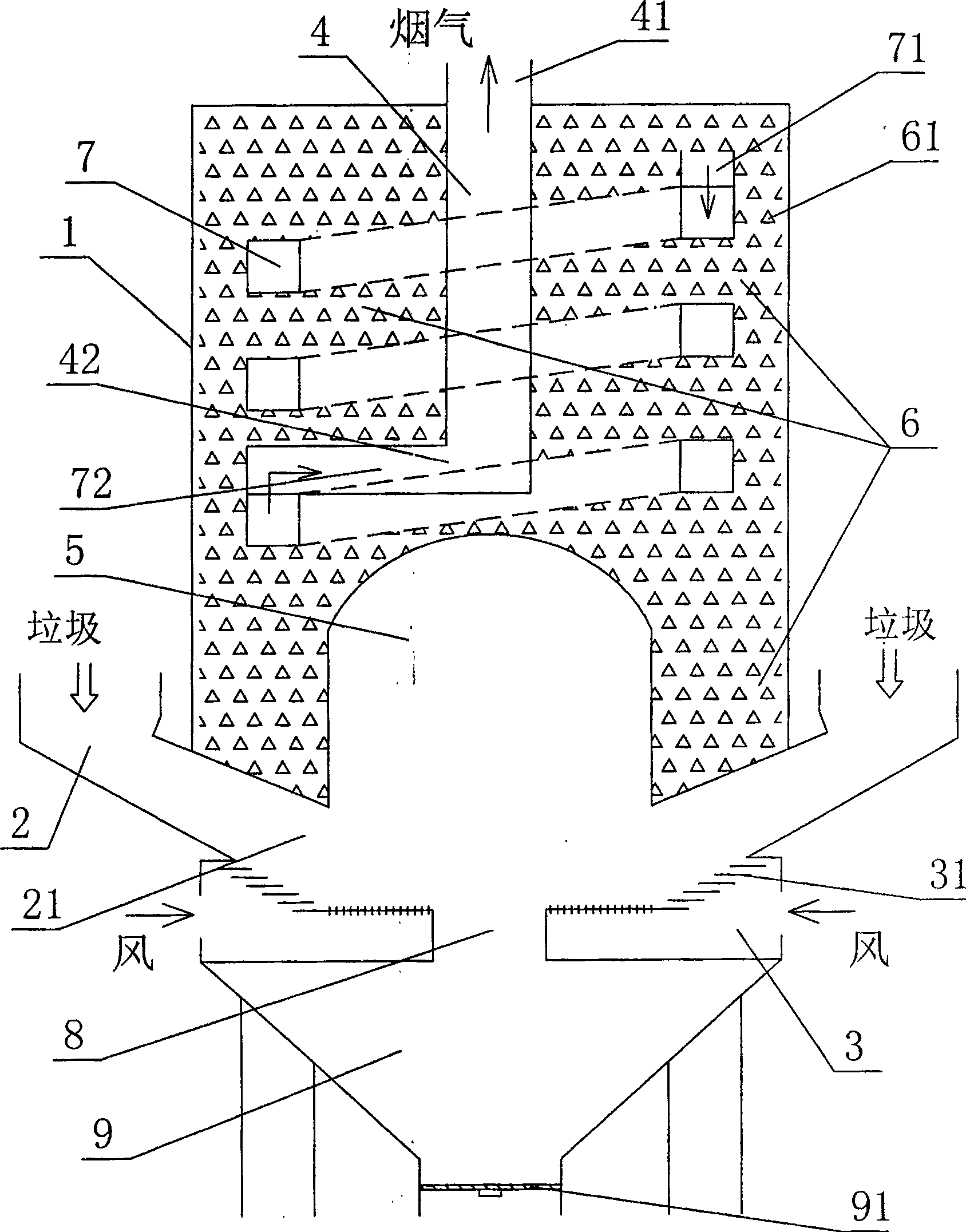

[0011] Such as figure 1 Shown is the schematic diagram of the structure of Embodiment 1 of the present invention, which includes a body of furnace 1 with a furnace. The body of furnace is provided with a feed passage 2, an air inlet passage 3 and a smoke exhaust passage 4. The first combustion chamber 5 communicated with the passage, and the second combustion chamber 6 communicated with the smoke exhaust passage. The first combustion chamber is a waste incineration cavity, and the second combustion chamber is filled with refractory materials 61, and the refractory materials are provided with mutual communication. gap (the refractory materials can be arranged regularly or irregularly); it is characterized in that: the furnace body is in the shape of a column, the first combustion chamber is located in the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com