Developer carrier and developing device

A developer and carrier technology, applied in the field of developing devices, can solve the problems of reduced toner charge, large resistance value change of resin coating layer, insufficient concentration stability or fog, etc., to achieve lubricity and wear resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0168]

[0169] Carbon black (hereinafter also referred to as "CB") with an average primary particle size of 14nm to 95nm is filled into a graphite crucible, heat-treated at 2000°C to 3200°C in a nitrogen atmosphere, and then graphitized to obtain graphite Carbon black (hereinafter also referred to as graphitized CB) A-1 to A-6. The measured physical property values of the obtained graphitized carbon blacks A-1 to A-6 are shown in Table 1. Table 1 also records the physical properties of carbon blacks a-1 to a-3 not subjected to graphitization treatment and carbon black a-4 prepared by changing the conditions of graphitization treatment. The temperature during the graphitization treatment is also described in Table 1.

[0170] Carbon black not subjected to graphitization treatment and raw material carbon black of graphitization treatment are as follows.

[0171] CB a-1: TOKA BLACK # 5500 (brand name) manufactured by TOKAI CARBON CO., LTD.

[0172] CB a-2: Ketjenblack EC-...

Embodiment 1

[0208] The developer carrier B-1 was evaluated according to the method shown below using a modified machine of a commercially available laser beam printer LBP-2510 (manufactured by Canon Co., Ltd., trade name).

[0209] First, remove the electrification auxiliary roller mounted on the developer carrier from the cyan process cartridge EP-85 (Canon Co., Ltd., trade name) for LBP-2510, fill the cyan process cartridge with developer 1, and then assemble the developing machine. Agent carrier B-1. And the rollers installed on the left and right sides of the developer carrier were replaced with rollers with a larger diameter, so that the gap distance between the developer carrier and the photosensitive drum was 280 μm. This modified cyan process cartridge was installed in the cyan position of the printer LBP-2510, and a dummy cartridge (dummy cartridge) was installed in another position, and monochrome evaluation was performed.

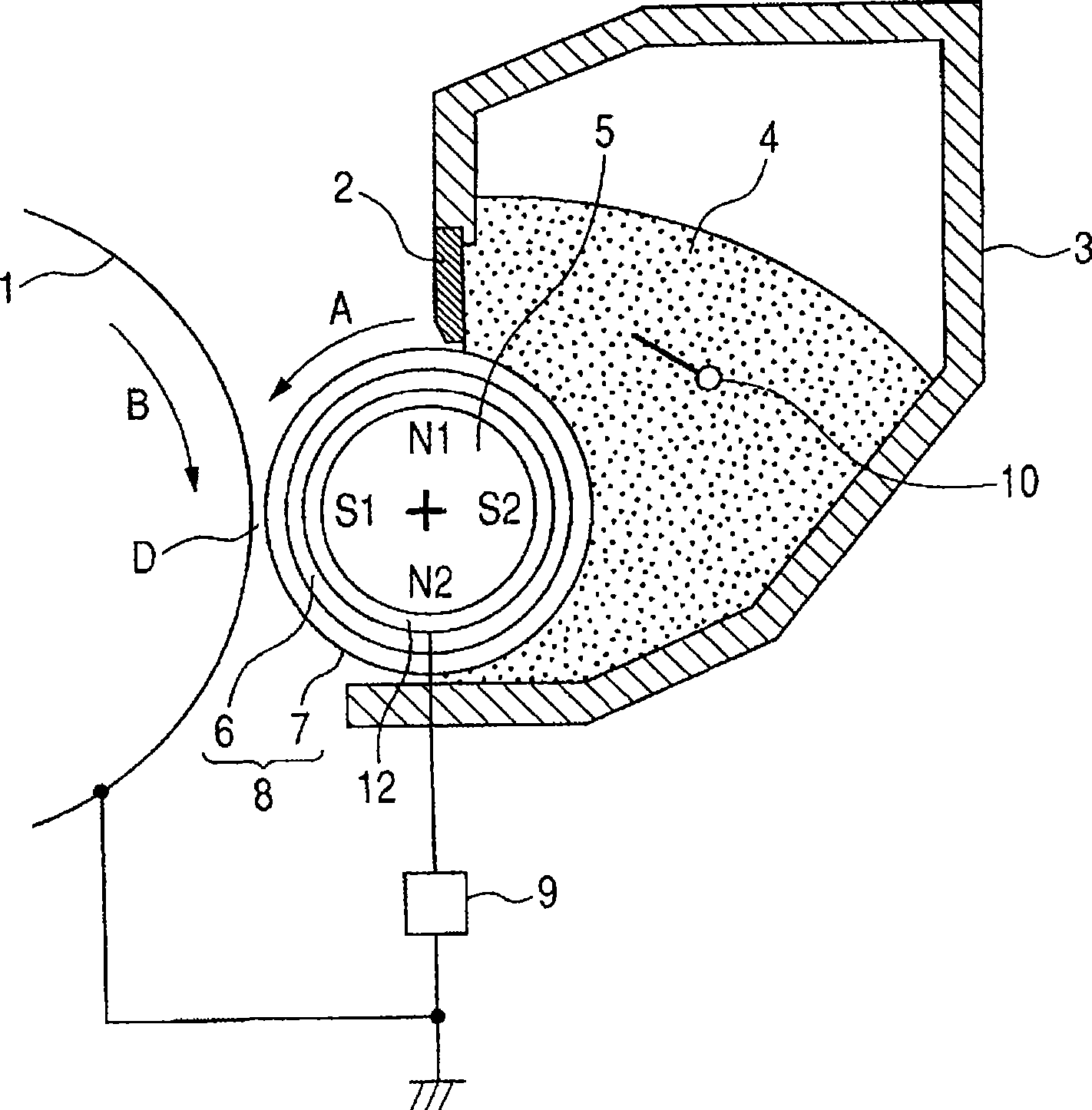

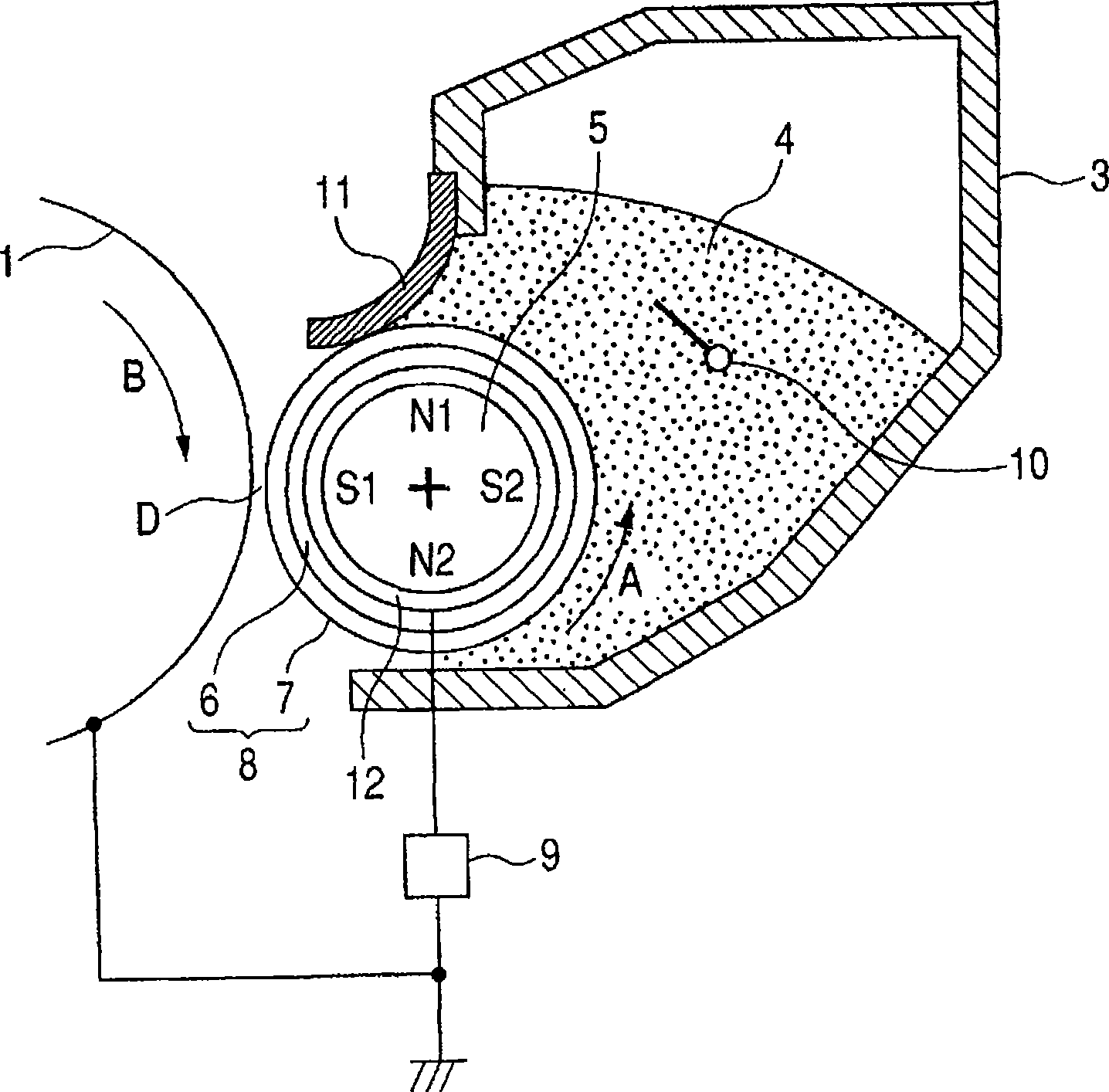

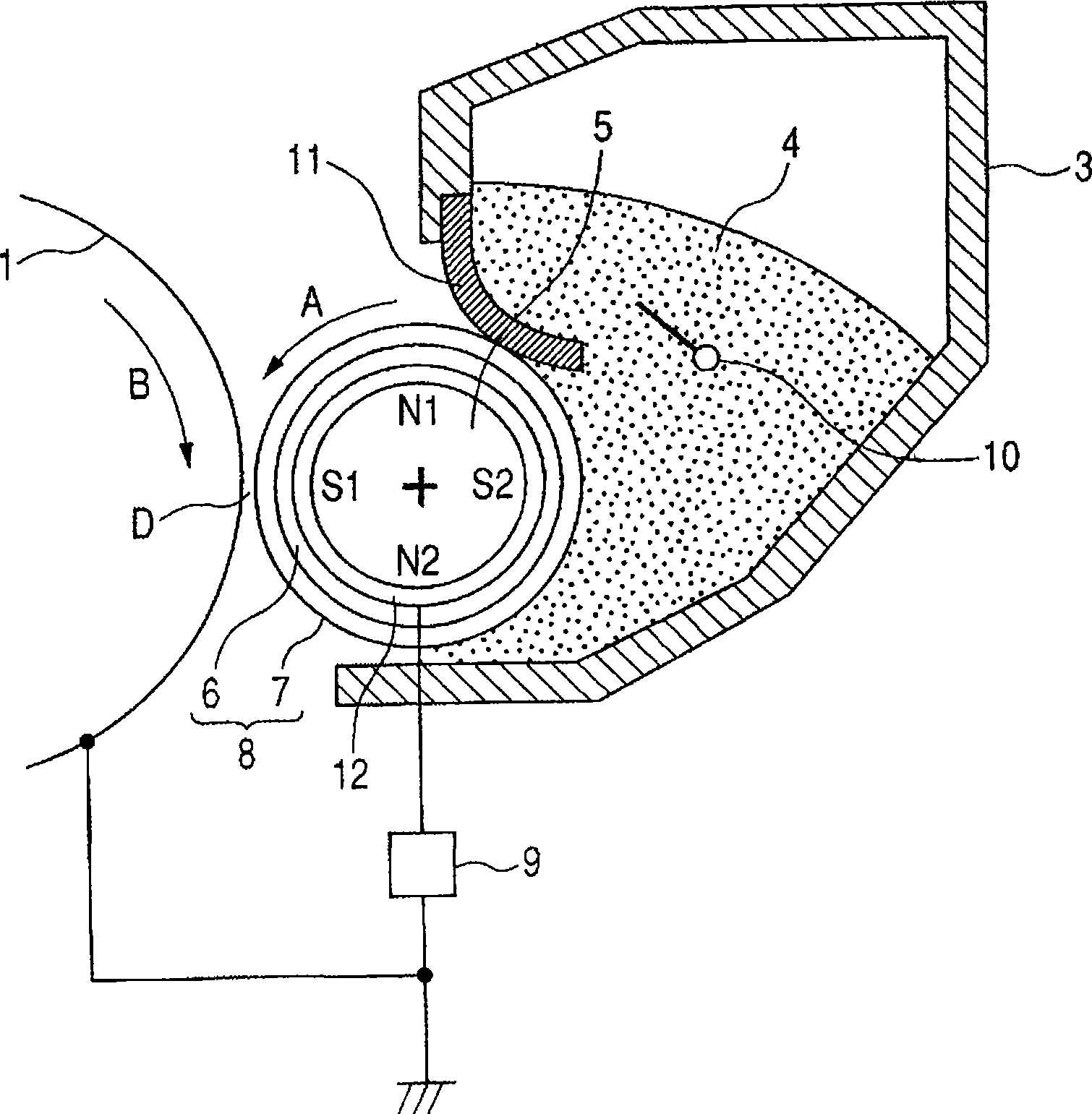

[0210] A schematic diagram of the developing device i...

Embodiment 2~6 and comparative example 1~4

[0252] The developer carriers B-2 to B-7 and b-1 to b-4 were respectively used as the developer carriers, and assembled into the process cartridge in the same manner as in Example 1, and then, in the same manner as in Example 1, Perform image evaluation. The results are shown in Table 3.

[0253] [table 3]

[0254]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com