Epoxy-zinc soap compound as heat stabilizer for polyvinyl chloride plastic formula

A heat stabilizer and polyvinyl chloride technology, which is applied in the field of compound zinc soap heat stabilizer, can solve the problems of unsuitability for melt processing and large content, and achieve the effects of good hue stability and improving equipment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

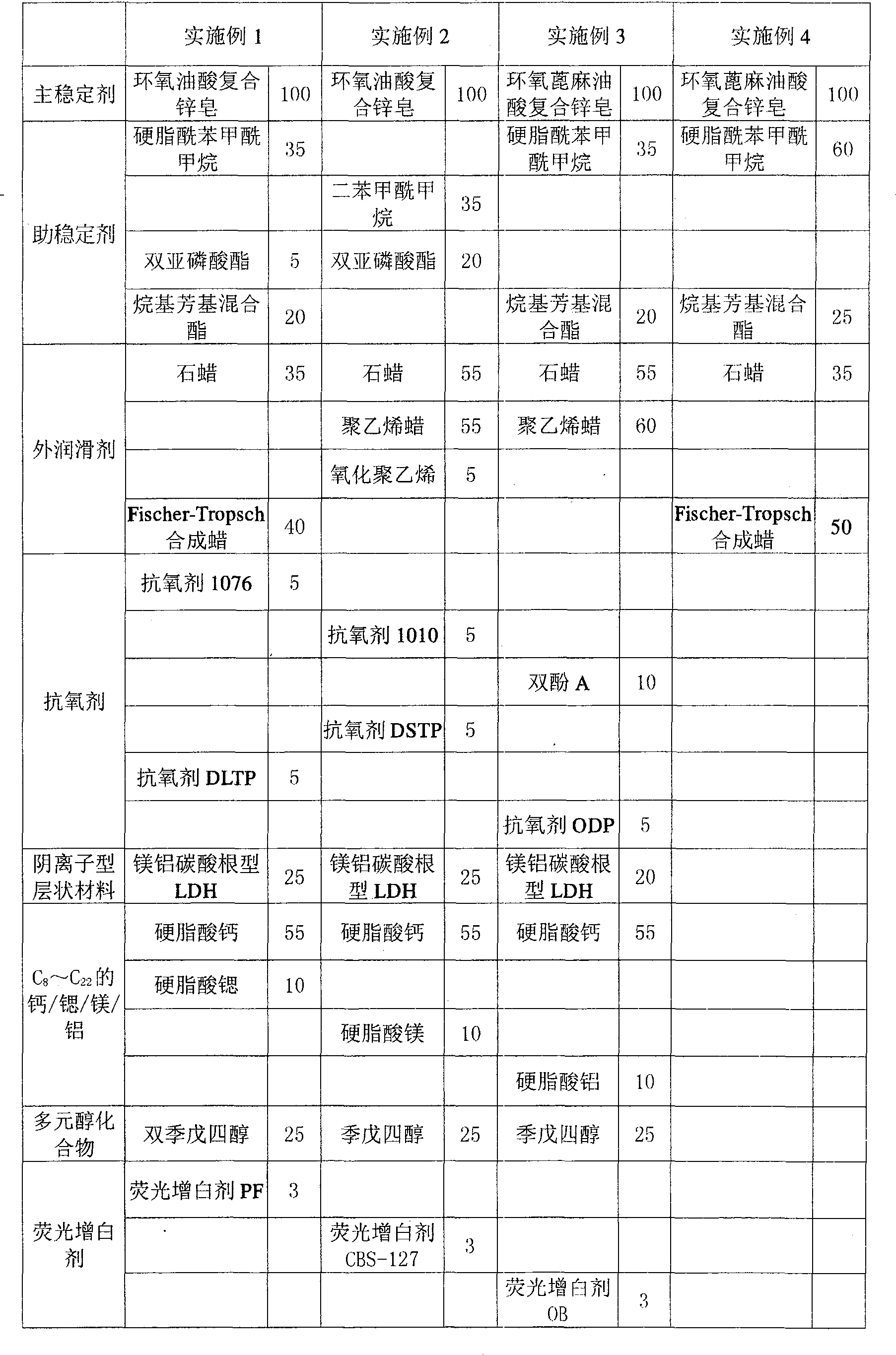

[0027] The epoxy composite zinc soap heat stabilizer for polyvinyl chloride of the present invention can be prepared by mixing the components uniformly in proportion by weight. The specific components and parts by weight of each embodiment are shown in Table 1.

[0028] Table 1

[0029]

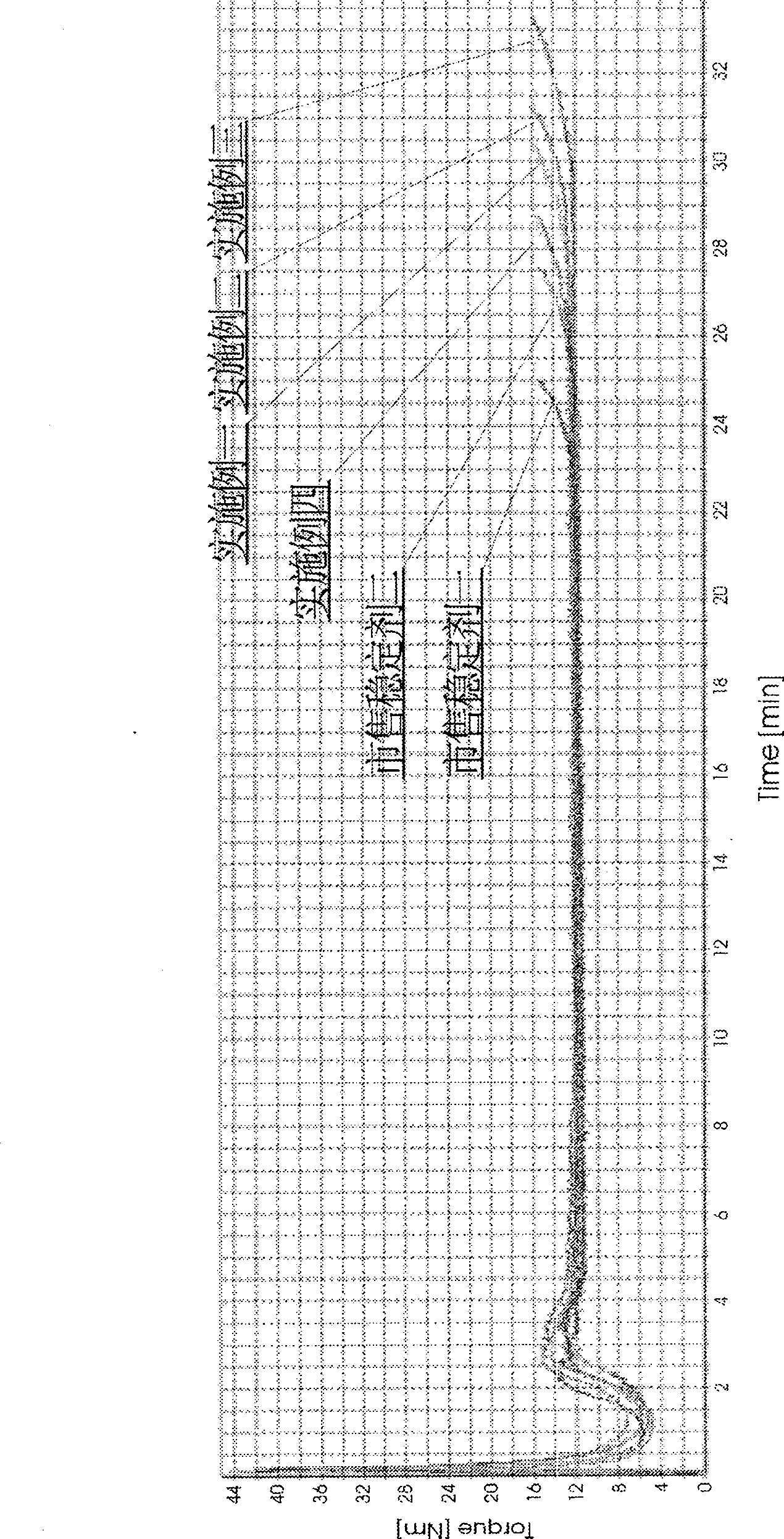

[0030] The test result of epoxy composite zinc soap heat stabilizer and commercially available calcium zinc heat stabilizer heat resistance performance comparison is as table 2 and figure 1 Shown:

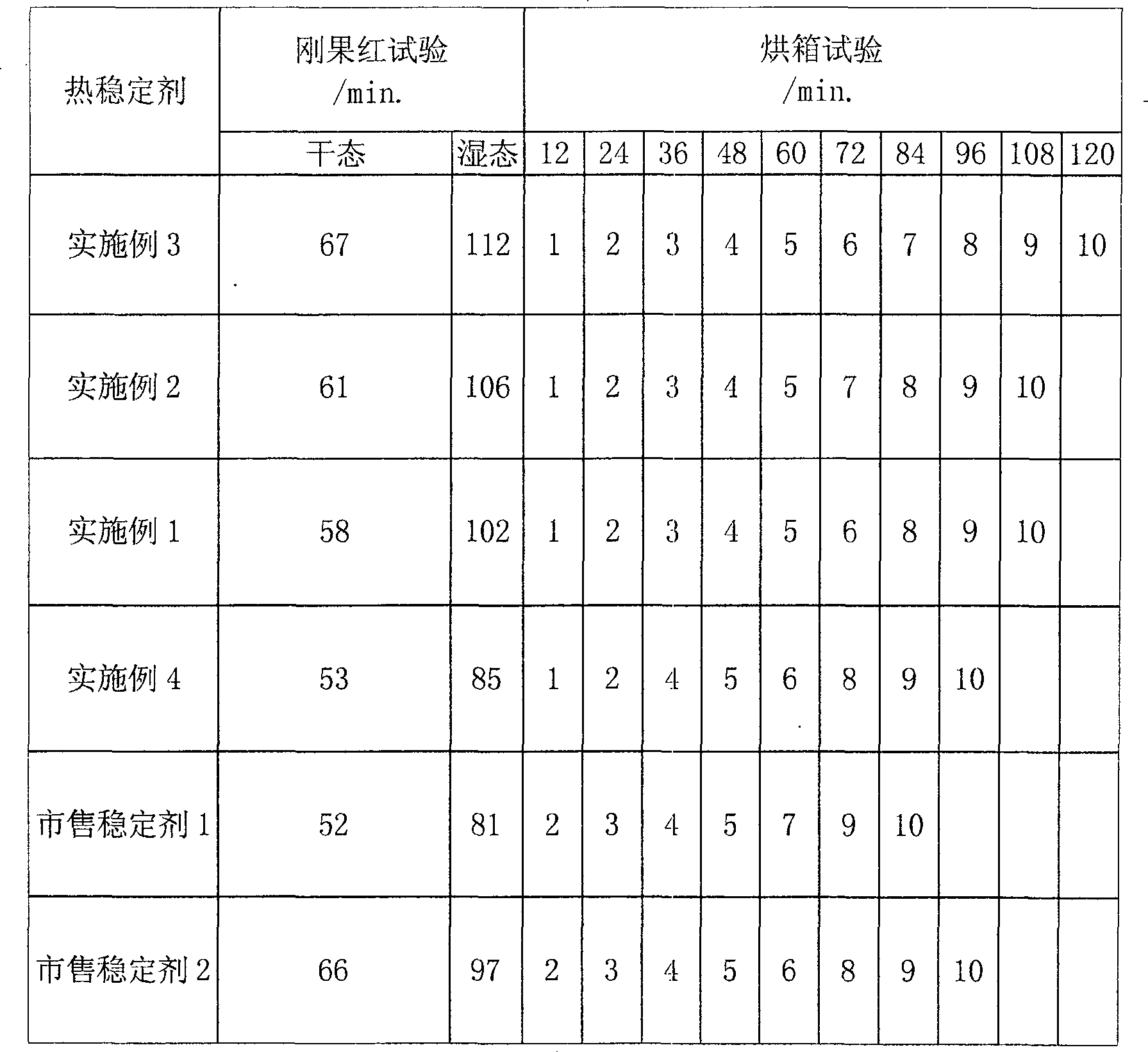

[0031] Table 2. Comparison of static thermal stability

[0032]

[0033] Note: dry state: 100 parts of PVC, 3.5 parts of heat stabilizer, grind and mix, and test according to GB2917-82 A method;

[0034] Wet state: 100 parts of PVC, 60 parts of DBP, 3.5 parts of heat stabilizer, other same as dry state test;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com