Inclination correcting mechanism of multi hinge nano-stamping pressing die

A technology of nano-imprinting and tilt correction, applied in printing presses, general parts of printing machinery, printing, etc., can solve the problems of deviation, low pressing precision, complicated structure, etc. good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

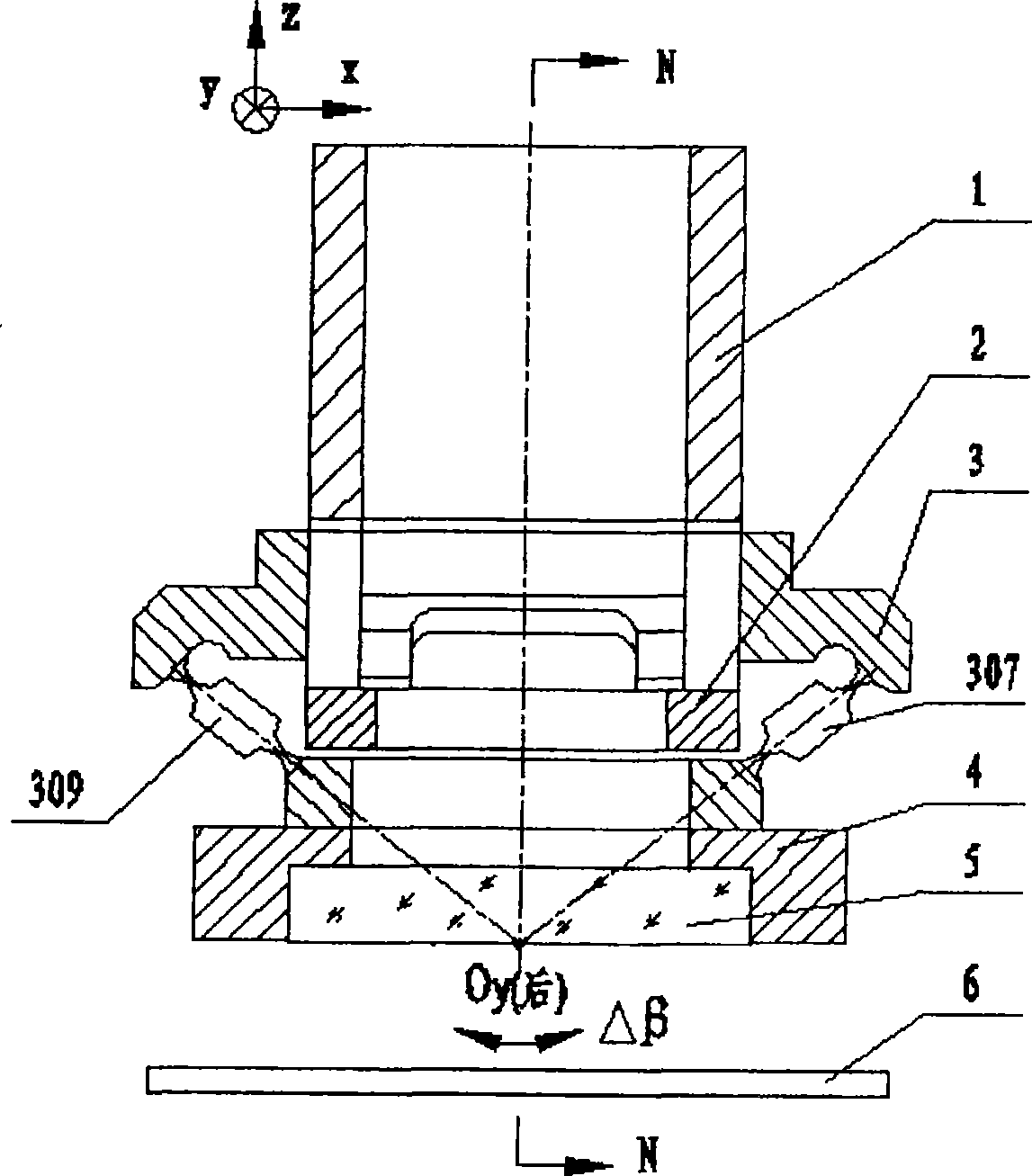

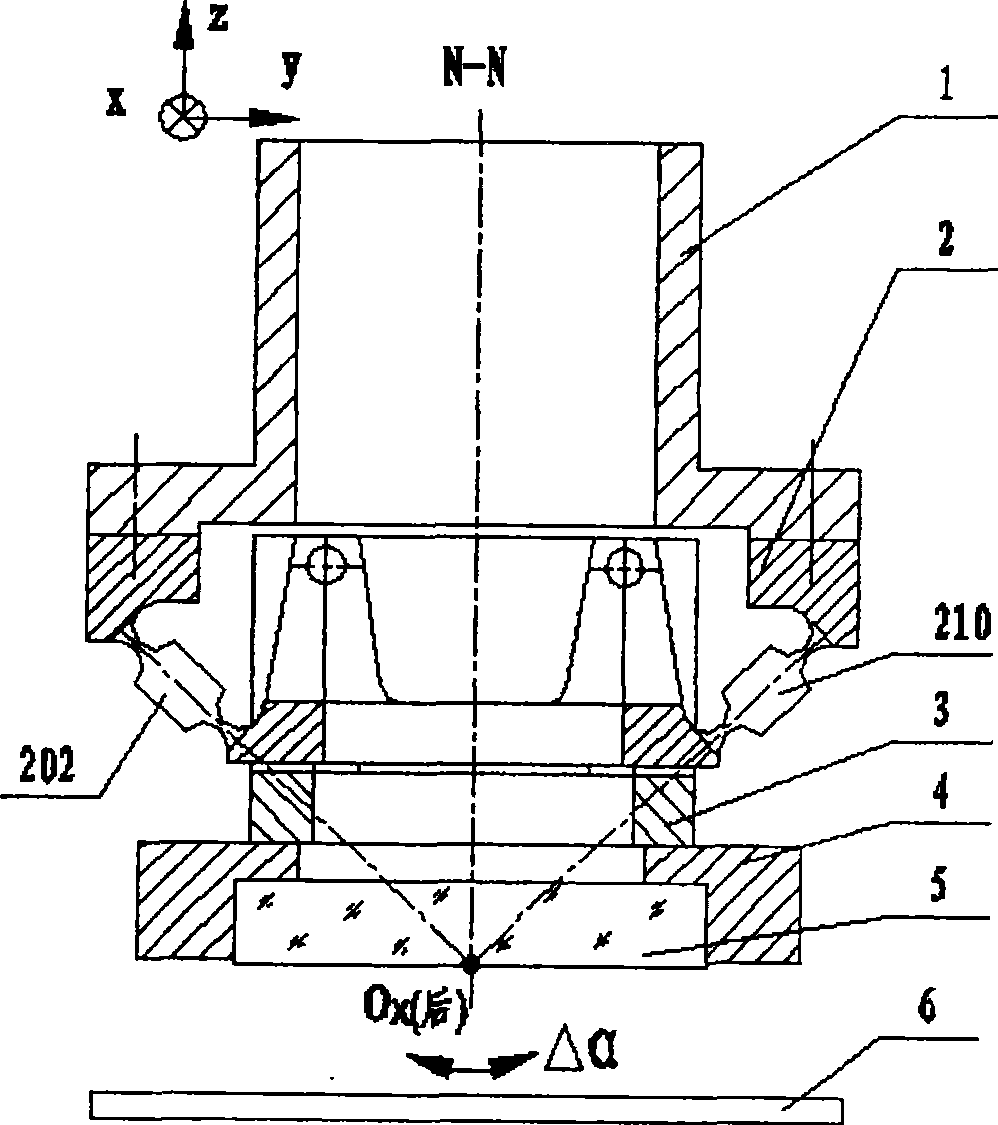

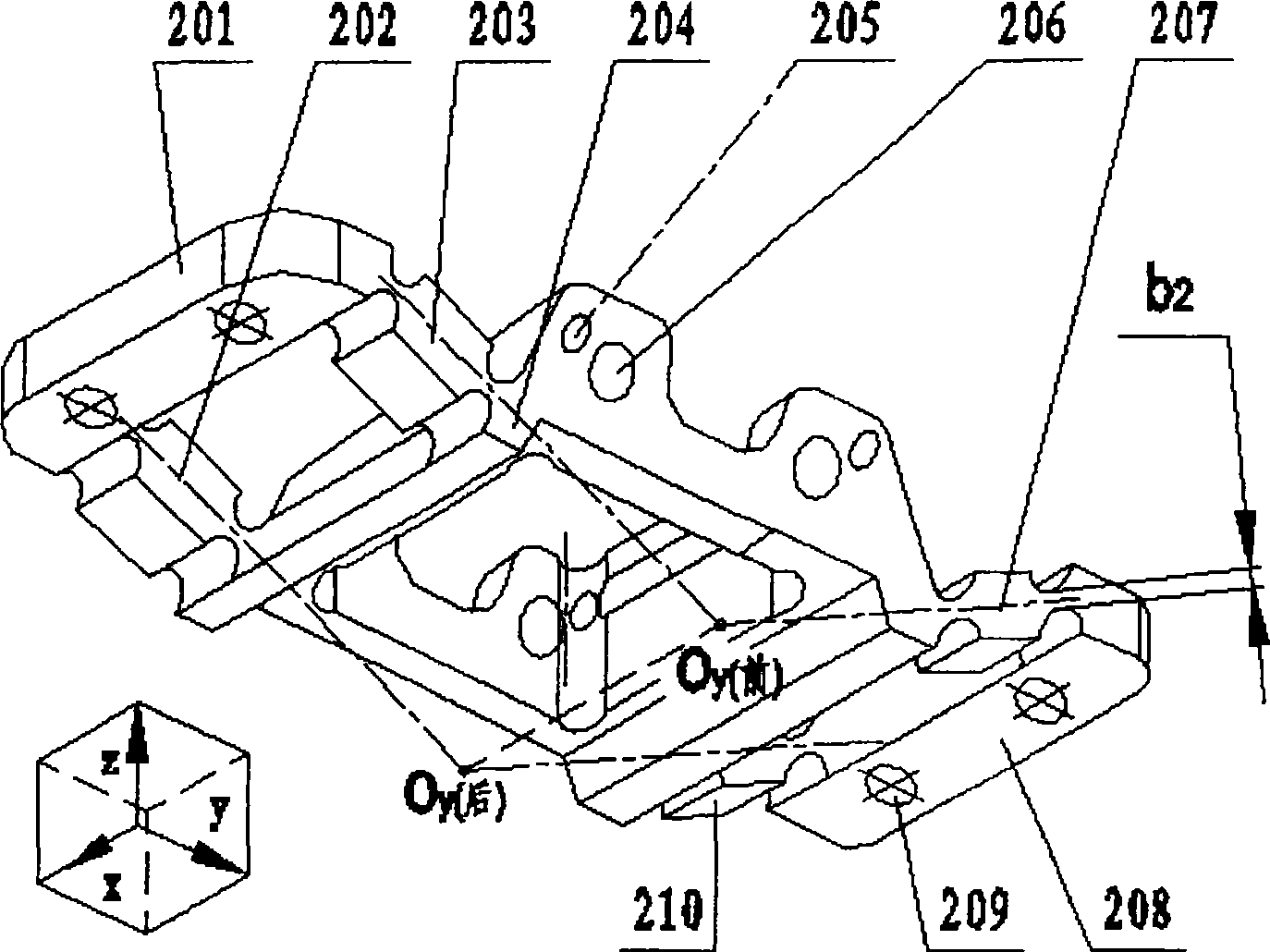

[0017] Such as figure 1 , 2 As shown, it is the front view of the multi-hinge structure of the embodiment of the present invention and its side sectional view. The present invention consists of an upper connecting sleeve 1, an upper hinge 2, a lower hinge 3, a die 5, a die chuck 4 and a substrate 6. The lower end surface of the upper connecting sleeve 1 is connected with the hinge seat of the upper hinge 2, the hinge seat of the lower hinge 3 is connected with the upper middle frame of the upper hinge 2, the lower middle frame of the lower hinge 3 is connected with the die chuck 4, and the die 5 Installed in the die chuck 4, the substrate 6 is located directly below the die 5. The lower pressure acts on the die 5 through the upper connecting sleeve 1, the upper hinge 2, the lower hinge 3 and the die chuck 4. The sheet 6 is not parallel, the moment generated by the first contact between the die 5 and the substrate 6 causes one or two hinges to rotate slightly, and the non-par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com