Electromagnetic impulse valve service lifetime rapid test device and test method thereof

A technology of electromagnetic pulse valve and testing device, which is applied in the direction of measuring device, testing of machine/structural components, instruments, etc., can solve the problems of increasing economic and energy consumption burden, huge testing device, long testing period, etc., and achieves rapid testing. , The effect of stable air pressure and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

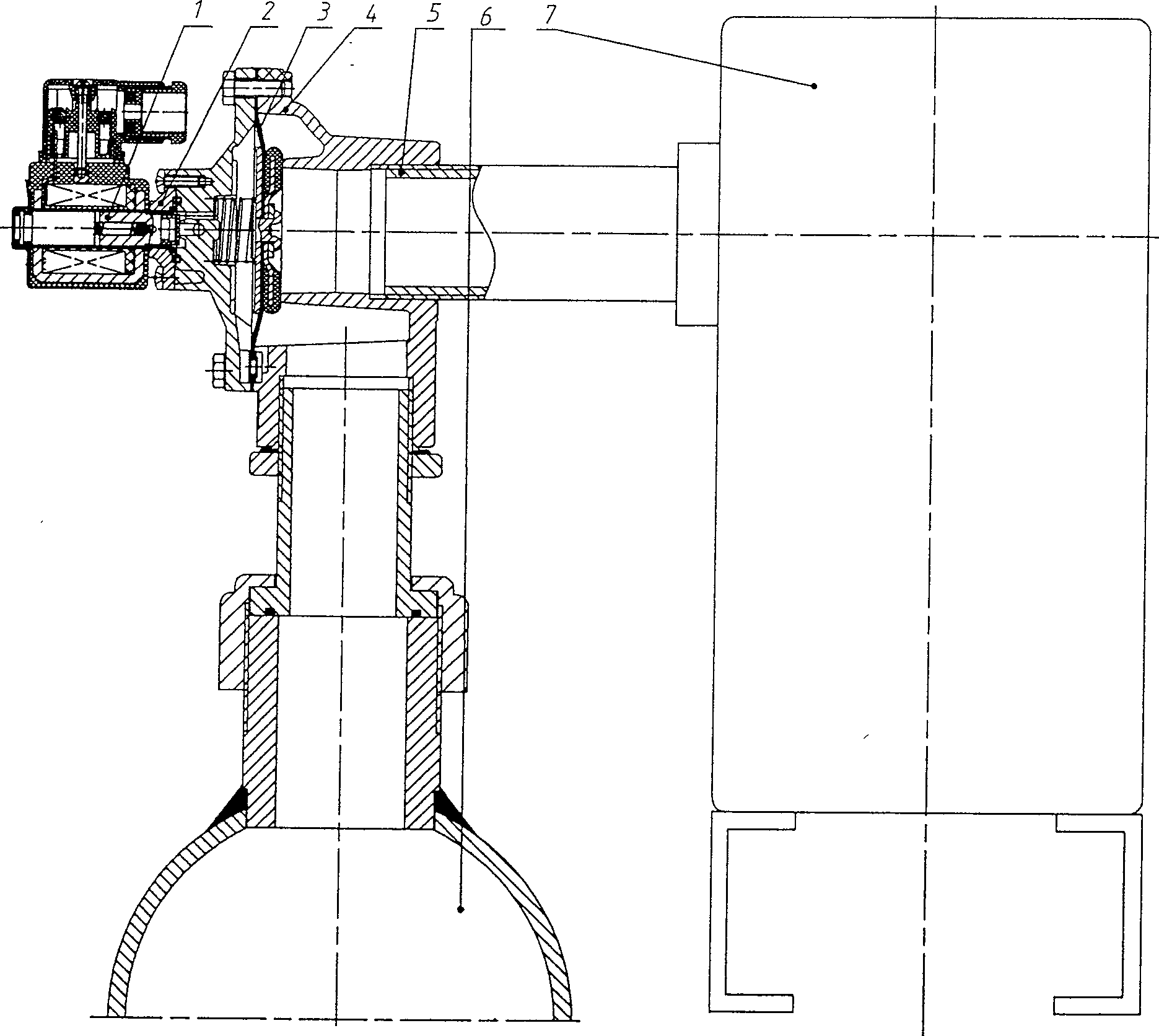

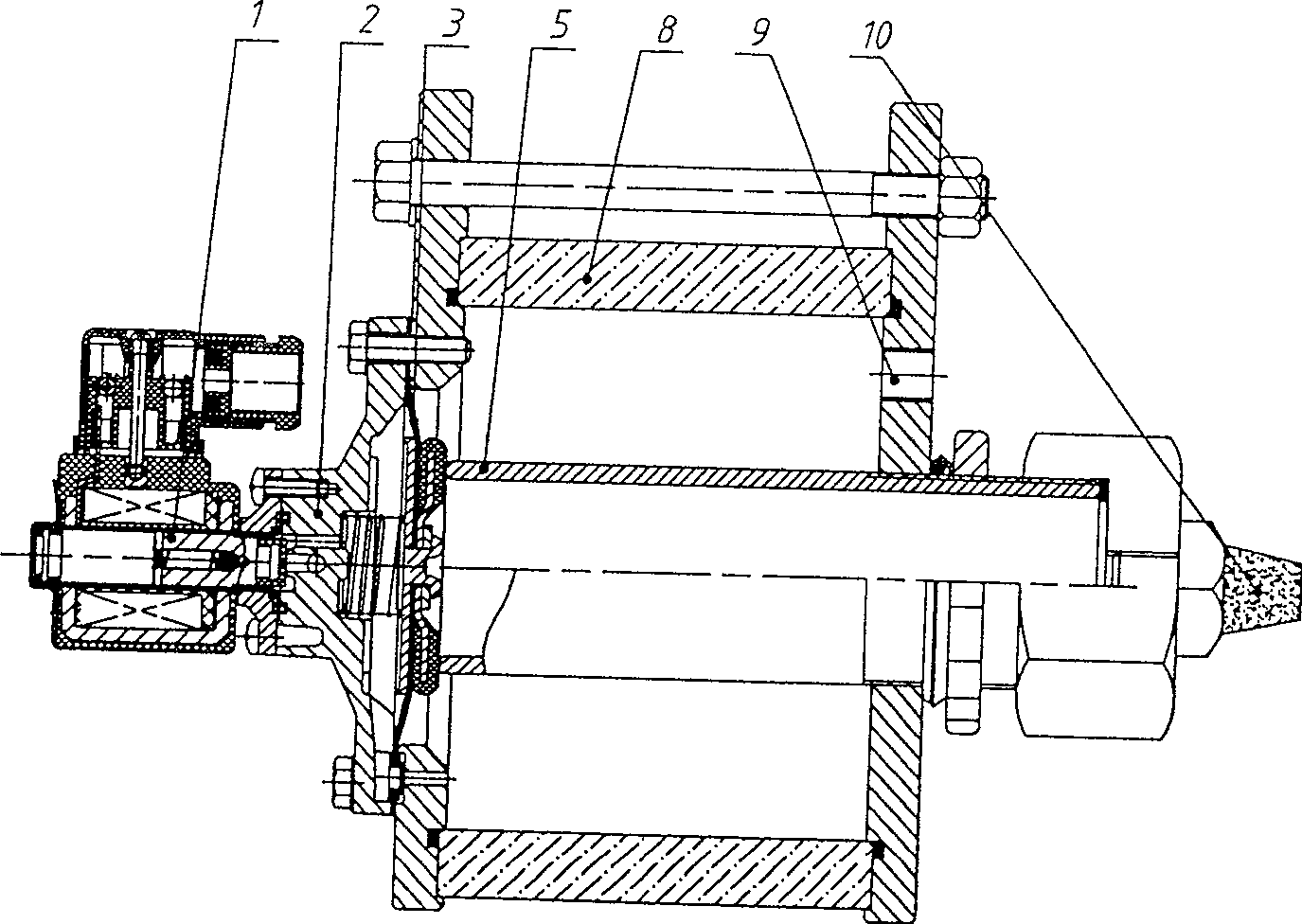

[0019] Such as figure 2 As shown, it is a schematic structural diagram of a quick test device for the service life of an electromagnetic pulse valve. The quick test device for a service life of an electromagnetic pulse valve consists of a solenoid head 1, a valve cover 2, a diaphragm 3, a blowing pipe 5, and a transparent box 8 And muffler mouth 10 forms.

[0020] The solenoid head 1 is connected with the valve cover 2, the valve cover 2 is connected with the transparent box end cover A12, the diaphragm 3 is fixed between the valve cover 2 and the transparent box end cover A12, and is in contact with one end of the blowing pipe 5, and the blowing pipe 5 passes through The other end of the transparent case 8 is closed or connected with the muffler nozzle 10 through a nut.

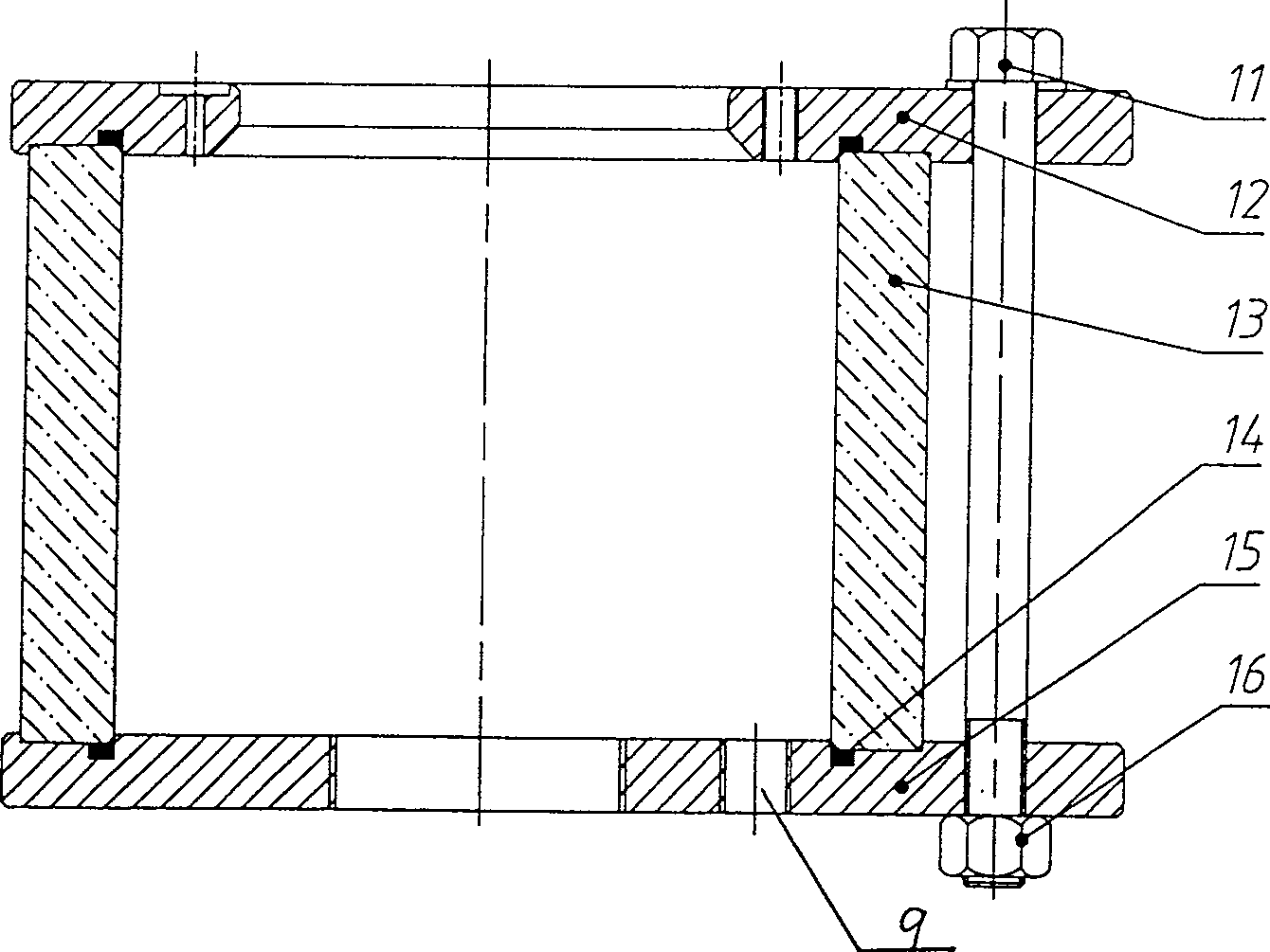

[0021] Described transparent box 8 is made up of air inlet 9, hexagonal bolt 11, end cover A12, plexiglass tube 13, seal ring 14, end cover B15, hexagonal nut 16, and organic glass tube 13 two sides are ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com