Noodle making method

A production method and noodle technology, which is applied in food preparation, application, food science, etc., can solve the problems of complex process, too soft taste of noodles, unsatisfactory preservatives, etc., and achieve the effect of preventing tissue changes and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~3

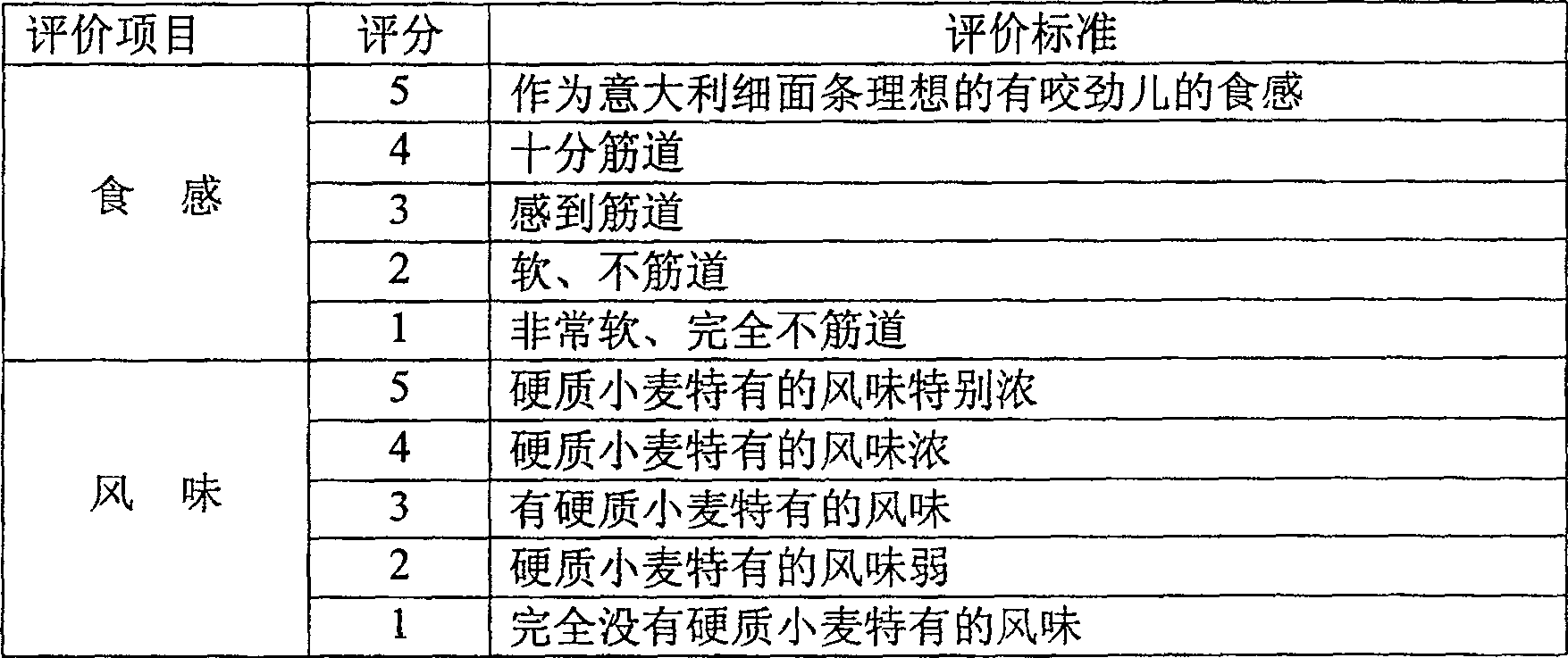

[0064] The spaghetti noodles were boiled to obtain boiled spaghetti noodles (yield rate 230%). The obtained boiled spaghetti was heat-treated by direct spray contact with the saturated water vapor shown in Table 1, and then the container was sealed. In Comparative Example 1, the boiled spaghetti was not heat-treated with saturated steam, and the container was directly sealed. After sealing for 1 day, it was heated, and 10 judges conducted a sensory evaluation on its taste and flavor according to the evaluation criteria in Table 2. The evaluation results are shown in Table 1.

[0065] Table 1

[0066]

implement

example 1 implement

Example 2 implement

Example 3 implement

Example 4 Compare

example 1 Compare

Example 2 Compare

Example 3 Water vapor temperature (℃) 105 120 140 150 — 100 160 Processing time (seconds) 30 30 30 30 — 30 30 Appetite (average score) 4.3 4.8 4.7 4.5 3.2 3.5 2.1 Flav...

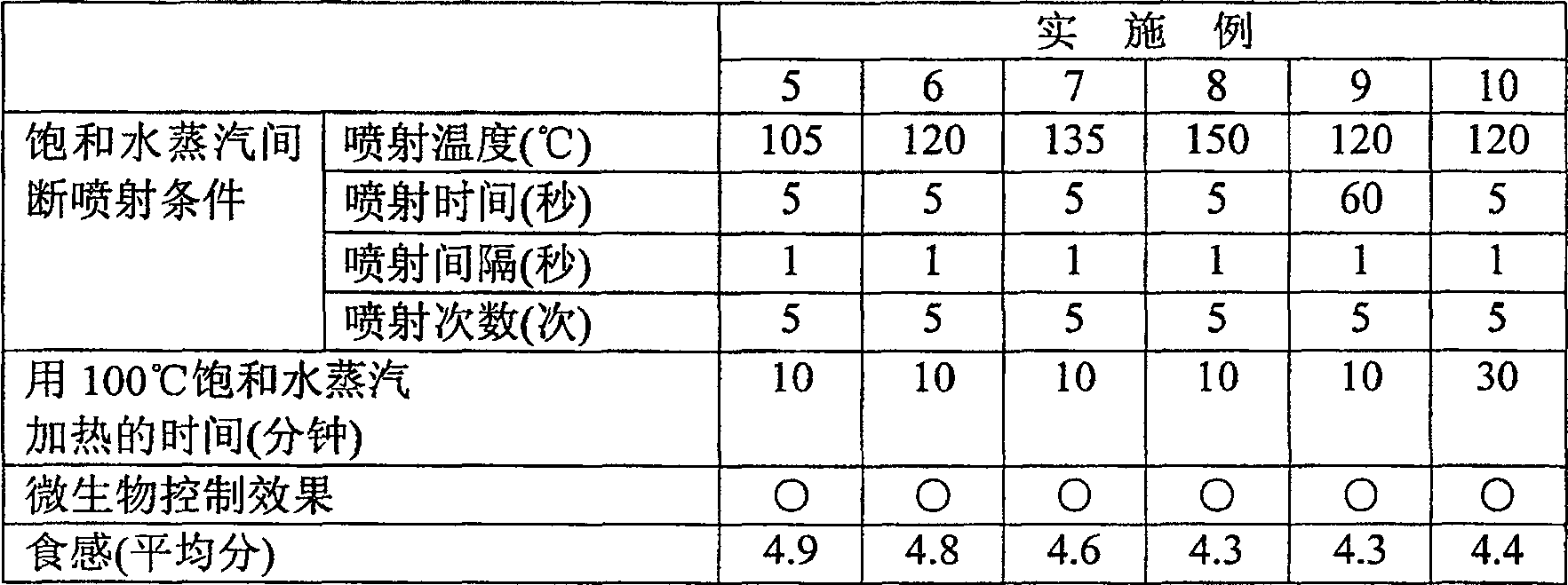

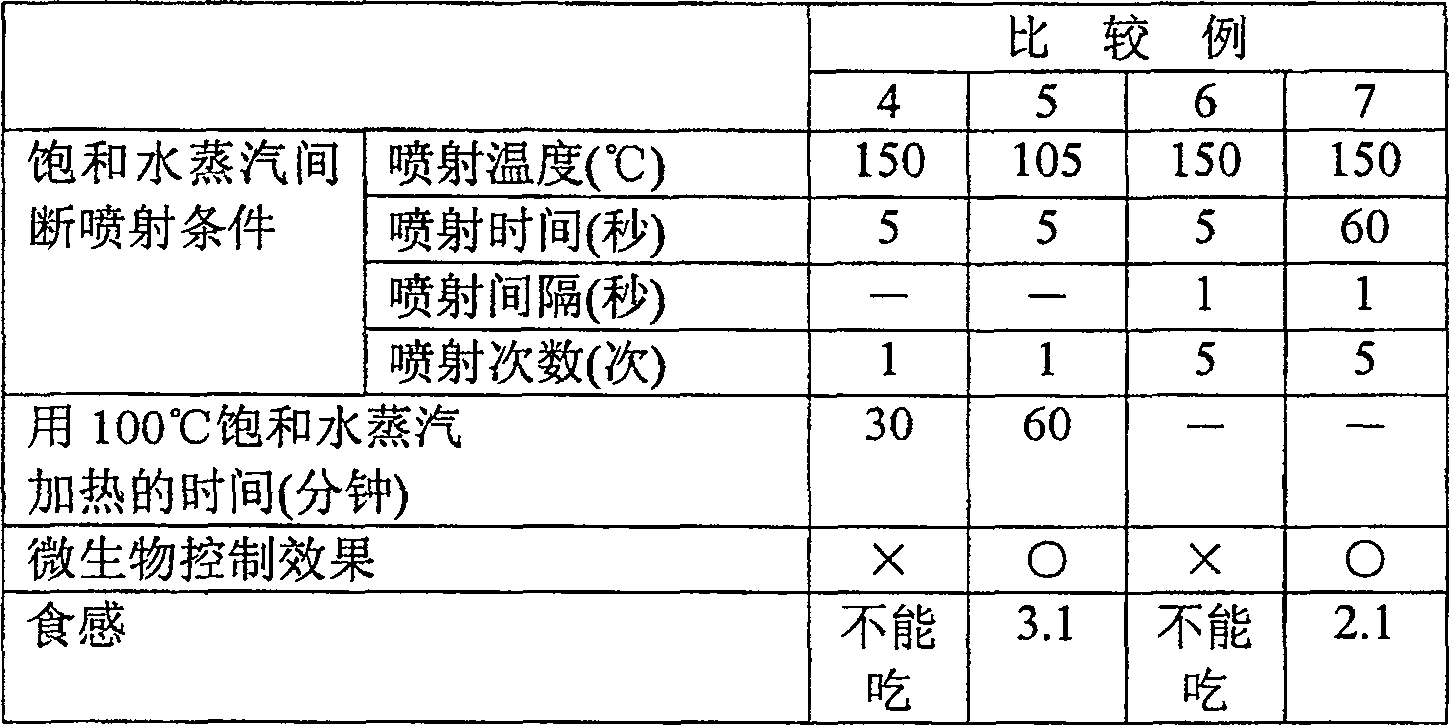

Embodiment 5~10 and comparative example 4~7

[0070] The dried spaghetti with a thickness of 1.6 mm was boiled until the yield reached 220%, and then immersed in water at 20° C. for 40 seconds to obtain boiled spaghetti. The boiled spaghetti was subdivided into 200 g, put into a container, and saturated steam was directly sprayed onto the boiled spaghetti under the spraying conditions shown in Table 3 and Table 4. Next, it was heated with saturated water vapor at 100° C. for the time shown in Table 3 and Table 4, and the lid of the container was immediately sealed to obtain spaghetti in a container. The obtained containerized spaghetti was allowed to cool to room temperature and stored for 1 week. Check the microbial proliferation after storage for 1 week, and evaluate the microbial control effect according to the standards shown in Table 5. Regarding the samples confirmed to have microbial control effects, 10 judges conducted a sensory evaluation on the food texture when heated with an electric stove according to the ev...

Embodiment 11

[0078]Dried spaghetti was boiled to a yield of 230%, and 200 g of the obtained boiled spaghetti was filled in a nylon / polypropylene laminated plastic dish-shaped container (120 mm inner diameter x 45 mm deep). Then, put the boiled spaghetti in the container into the chamber of the retort sterilization device, and spray the saturated steam with a temperature of 120° C. for 30 seconds to carry out the repressurization and heat treatment, thereby the spaghetti is sterilized. Then, open and close the pressure control valve installed in the room once. The temperature in the chamber after the operation was 115°C. Then fully open the pressure control valve until the indoor pressure becomes atmospheric pressure. Then, the opening of the container was aseptically sealed according to a conventional method to obtain boiled spaghetti in a container. Before entering the sealing operation, the indoor container filling boiled spaghetti did not spray out from the container, and the state of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com