A carbon-coated janus structure metal/metal oxide composite catalyst and its preparation and application

A technology of composite catalysts and oxides, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as the difficulty in synergistically exerting the catalytic effects of metals and oxides , to achieve the effect of avoiding organizational changes, wide application range and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

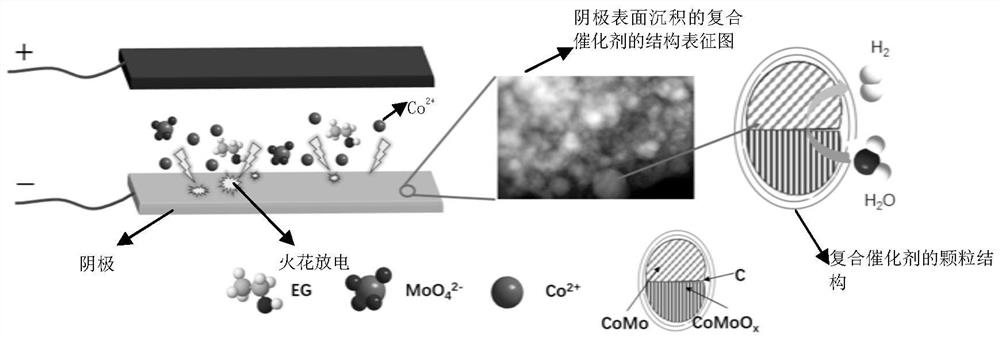

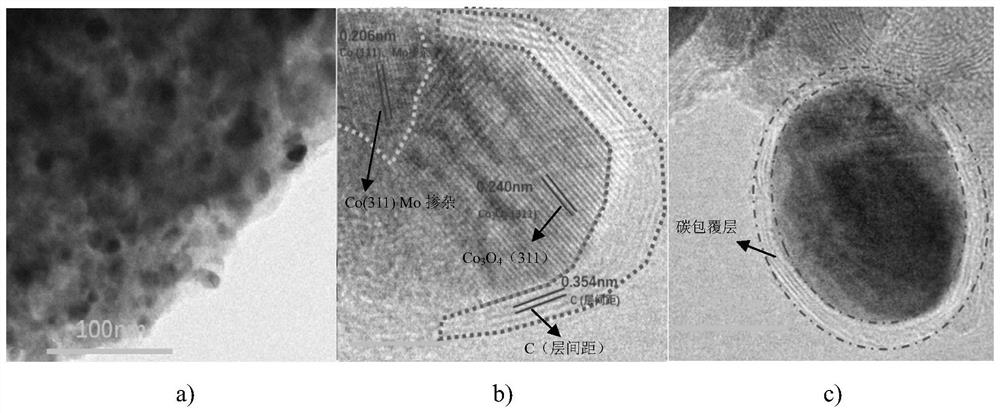

[0045] A carbon-coated Janus structure metal / metal oxide composite catalyst (CoMo / CoMoO x @C) preparation method, comprises the following steps:

[0046] (1) Conductive substrate pretreatment: Cut the pure copper sheet into a rectangle with a size of 1x5cm, ultrasonically clean the cut pure copper sheet in acetone for 15 minutes, and then ultrasonically clean it in absolute ethanol for 10 minutes. After cleaning in acetone and anhydrous Rinse with plenty of deionized water after ethanol cleaning.

[0047] (2) Cathode plasma electrodeposition: Dissolve cobalt nitrate, sodium molybdate, sodium citrate and EDTA-2Na in a mixed solution of ethylene glycol and water, where the volume ratio of ethylene glycol and water is 3:2 to obtain electrolysis Liquid, the concentration of cobalt nitrate in the electrolyte is 0.1mol / L, the concentration of sodium molybdate 0.1mol / L, the concentration of sodium citrate is 0.05mol / L and the concentration of EDTA-2Na is 0.02mol / L; With step ( 1) T...

Embodiment 2

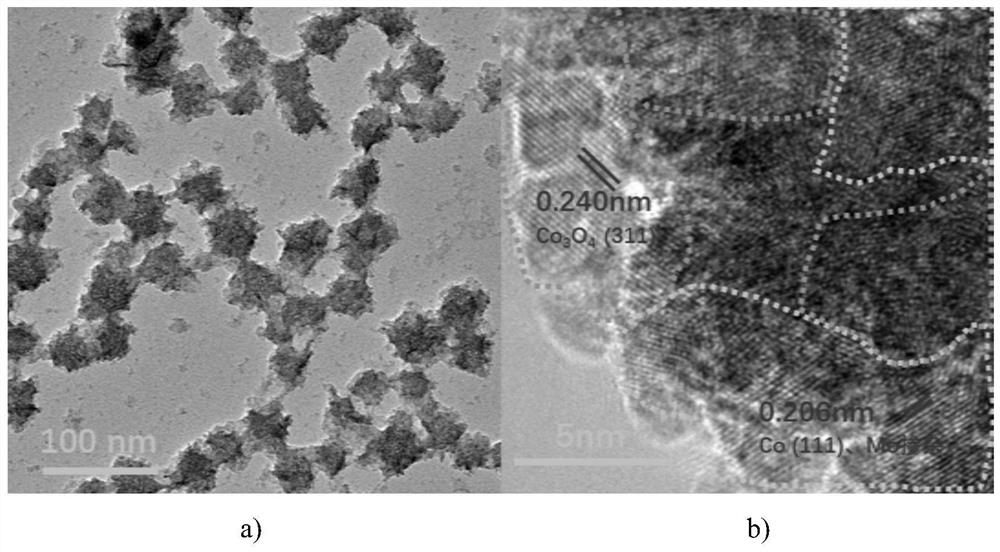

[0069] A kind of preparation method of carbon coating Janus structure metal / metal oxide composite catalyst, comprises the following steps:

[0070] (1) substrate pretreatment, same as embodiment 1 step (1);

[0071] (2) Cathode plasma electrodeposition: Dissolve nickel sulfate, sodium molybdate, sodium citrate and EDTA-2Na in a mixed solution of ethylene glycol and water, where the volume ratio of ethylene glycol and water is 3:2 to obtain electrolysis Liquid, the concentration of nickel sulfate in the electrolytic solution is 0.1mol / L, the concentration of sodium molybdate 0.1mol / L, the concentration of sodium citrate is 0.05mol / L and the concentration of EDTA-2Na is 0.02mol / L; With step ( 1) The pretreated pure copper sheet is used as the cathode, and the platinum sheet is used as the anode for cathode plasma electrodeposition. The power supply voltage is set to 130V, and the electrodeposition time is 5min. After the sample preparation is completed, the residual solution on ...

Embodiment 3

[0074] A kind of preparation method of carbon coating Janus structure metal / metal oxide composite catalyst, comprises the following steps:

[0075] (1) substrate pretreatment, same as embodiment 1 step (1);

[0076] (2) Cathode plasma electrodeposition: Dissolve nickel sulfate, cobalt nitrate, sodium citrate and EDTA-2Na in a mixed solution of ethylene glycol and water, wherein the volume ratio of ethylene glycol to water is 3:2 to obtain an electrolyte , the concentration of cobalt nitrate in the electrolyte is 0.1mol / L, the concentration of nickel sulfate 0.1mol / L, the concentration of sodium citrate is 0.05mol / L and the concentration of EDTA-2Na is 0.02mol / L; With step (1) The pretreated pure copper sheet is used as the cathode, and the platinum sheet is used as the anode for cathode plasma electrodeposition. The power supply voltage is set to 130V, and the electrodeposition time is 5 minutes. After the sample preparation is completed, the residual solution on the surface i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com