Copper catalyst for synthesizing organic silicon monomer and its preparation process

A copper catalyst and organosilicon technology, applied in catalyst activation/preparation, organic silicon compounds, chemical instruments and methods, etc., can solve the problem of insufficient comprehensive performance such as activity and selectivity, high requirements for pure copper powder raw materials, and copper Insufficient oxide content, etc., to achieve the effect of easy control of the reaction process, shortening of dehydration time, reduction of energy consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A copper catalyst for organosilicon monomer synthesis, characterized in that: it is made of copper sulfate pentahydrate as raw material, after spray drying, dehydration, reduction and partial oxidation, and the composition and weight percentage of its composition are as follows:

[0028] Cuprous oxide 71.12%, metallic copper 14.23%, copper oxide 13.18%

[0029] The preparation method of the copper catalyst used for the synthesis of the organosilicon monomer comprises the following processing steps:

[0030] A, pretreatment of raw materials: the CuSO 4 ·5H 2 O dissolved and filtered to remove impurities.

[0031] B. Spray drying and dehydration: The completely combusted natural gas is directly mixed with CuSO after removing impurities through a spray dryer 4 Solution contact, CuSO 4 The solution is dehydrated and dried to CuSO 4 ·H 2 O.

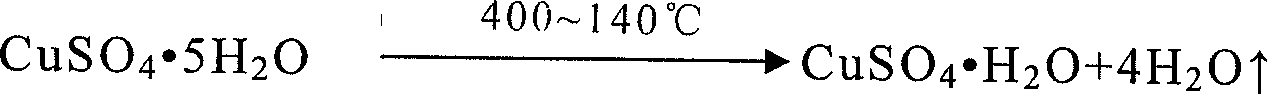

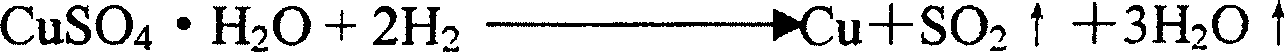

[0032] The temperature of the spray drying and dehydration is 400-160°C, and its chemical reaction formula is as follows:

[0...

Embodiment 2

[0039] A copper catalyst for organosilicon monomer synthesis, characterized in that: it is made of copper sulfate pentahydrate as raw material, after spray drying, dehydration, reduction and partial oxidation, and the composition and weight percentage of its composition are as follows:

[0040] Cuprous oxide 36.96% Metal copper 52.07% Copper oxide 3.09%

[0041] The preparation method of the copper catalyst used for the synthesis of the organosilicon monomer comprises the following processing steps:

[0042] A, pretreatment of raw materials: the CuSO 4 ·5H 2 O dissolved and filtered to remove impurities.

[0043] B. Spray drying and dehydration: the completely combusted liquefied gas is directly mixed with CuSO after removing impurities through a spray dryer 4 ·5H 2 Dehydration and drying into CuSO after O contact 4 ·H 2 O.

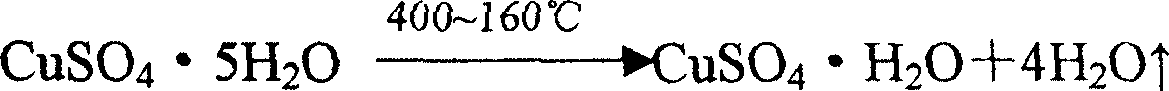

[0044] The temperature of the spray drying and dehydration is 400-170°C, and its chemical reaction formula is as follows:

[0045]

[0046] C....

Embodiment 3

[0051] A copper catalyst for organosilicon monomer synthesis, characterized in that: it is made of copper sulfate pentahydrate as raw material, after spray drying, dehydration, reduction and partial oxidation, and the composition and weight percentage of its composition are as follows:

[0052] Cuprous oxide 61.76%, metallic copper 28.85%, copper oxide 6.62%

[0053] The preparation method of the copper catalyst used for the synthesis of the organosilicon monomer comprises the following processing steps:

[0054] A, pretreatment of raw materials: the CuSO 4 ·5H 2 O dissolved and filtered to remove impurities.

[0055] B. Spray drying and dehydration: The hot gas after the complete combustion of natural gas, liquefied petroleum gas or other combustible gases is directly mixed with CuSO after removing impurities through a spray dryer 4 Solution contact, CuSO 4The solution is dehydrated and dried to CuSO 4 ·H 2 O.

[0056] The temperature of the spray drying and dehydratio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap