Automatic tool change device

A technology for automatic tool and tool replacement, applied in the direction of feeding device, manufacturing tool, positioning device, etc., can solve the problem of impossible to rotate the holding device and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

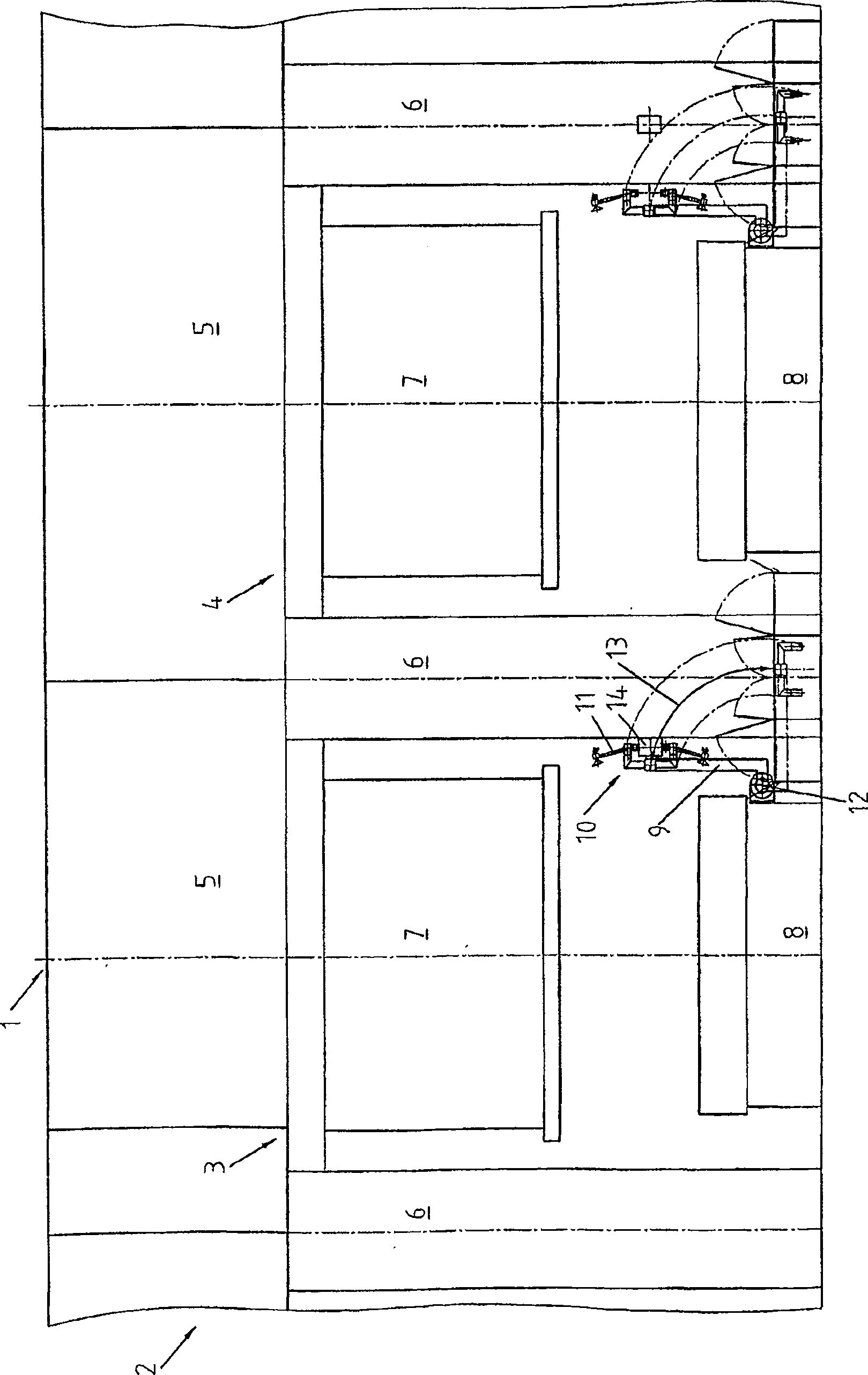

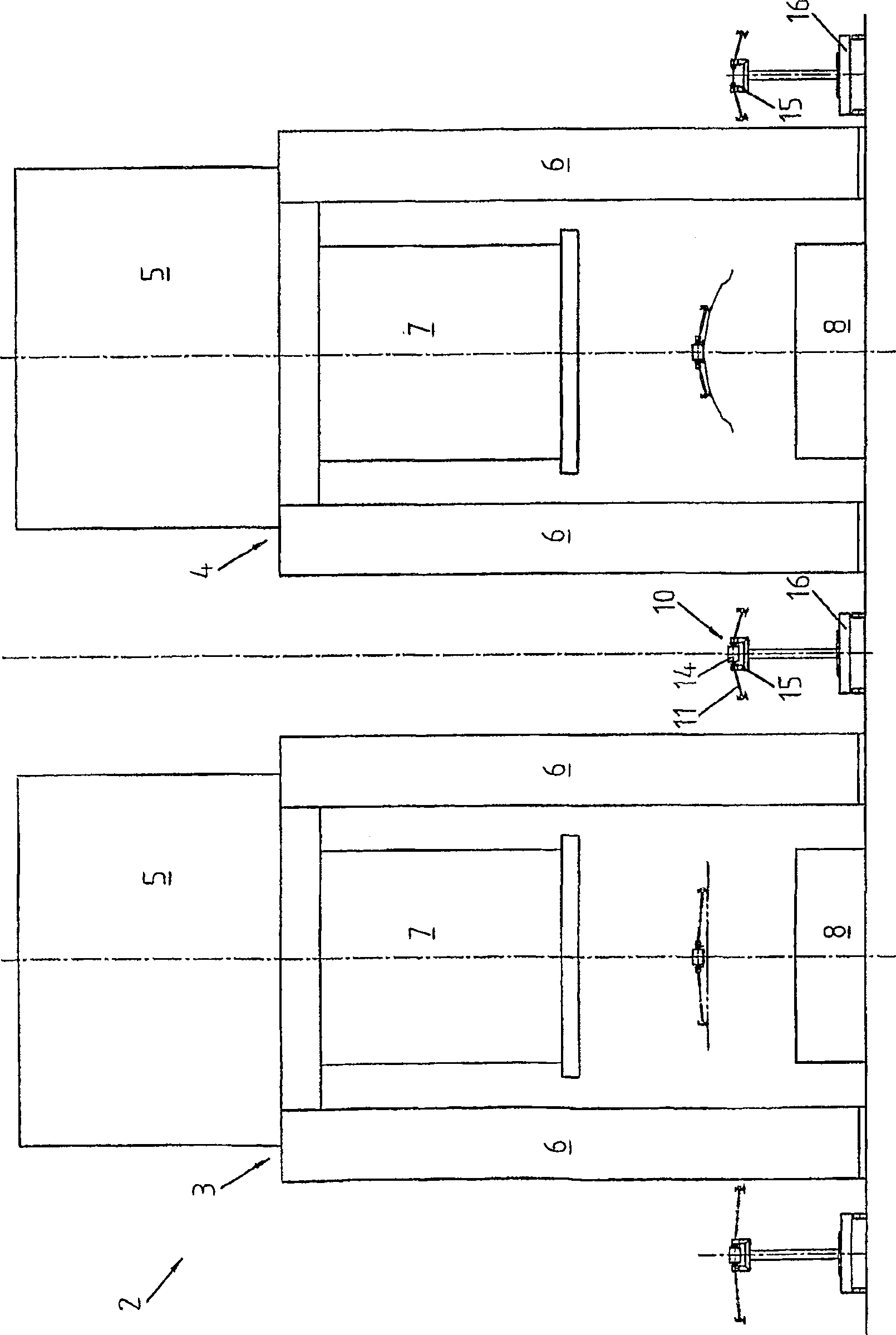

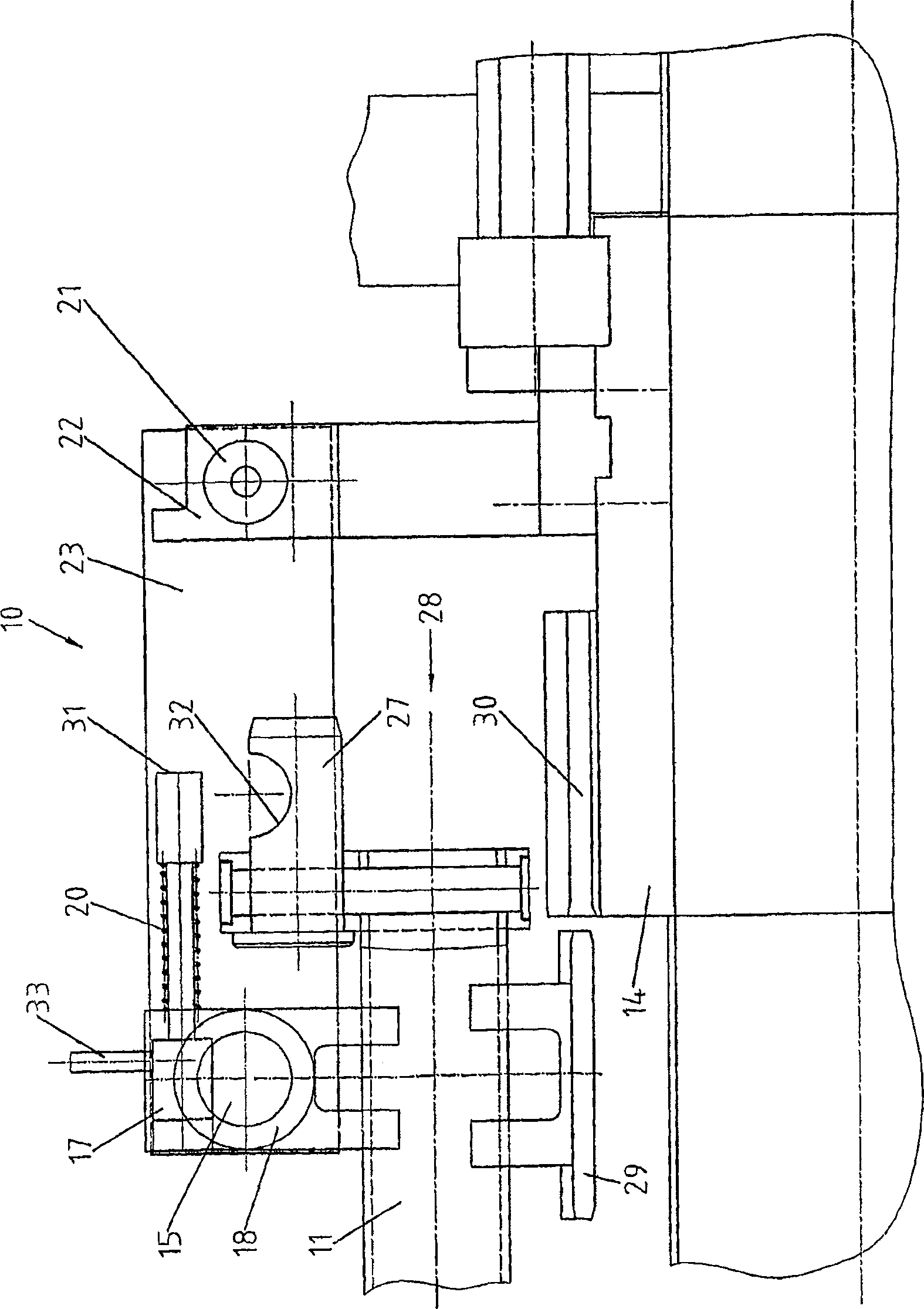

[0040] figure 1 A simplified diagram of a part of a large part transfer press 1 is shown. The figures show machining stages 3 and 4 with head piece 5 , column 6 and slide 7 . Since the tool changing system as claimed in the invention is independent of the type of parts transfer system, the latter is not shown in detail. Only the automatic tool changing system 10 is shown with the beam 14 mounted thereon. A rotary device 9 for holding the automatic tool changer 10 and the tool 11 is mounted on the slide table 8 . In this embodiment, in the event of a tool change, the tool 11 locked on the rotary device 9 is moved out of the large part transfer press 1 together with the slide table 8 and the changed tool is subsequently moved into the large part transfer press 1 . The swivel device 9 serves as a holding device for the tool 11 and is mounted on the slide table 8 so that it can be swiveled at a swivel point 12 . In the case of a tool change, as soon as the tool 11 is detached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com