Special pressure for industrial detonating cap and method for compressing detonating cap explosive

A press and detonator technology, applied in the field of press manufacturing, can solve the problems that are not conducive to the use of automatic detonator filling lines, large basic investment in hydraulic pump stations, and large volume of hydraulic presses, etc., to achieve convenient automatic control, low equipment cost, and basic investment Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

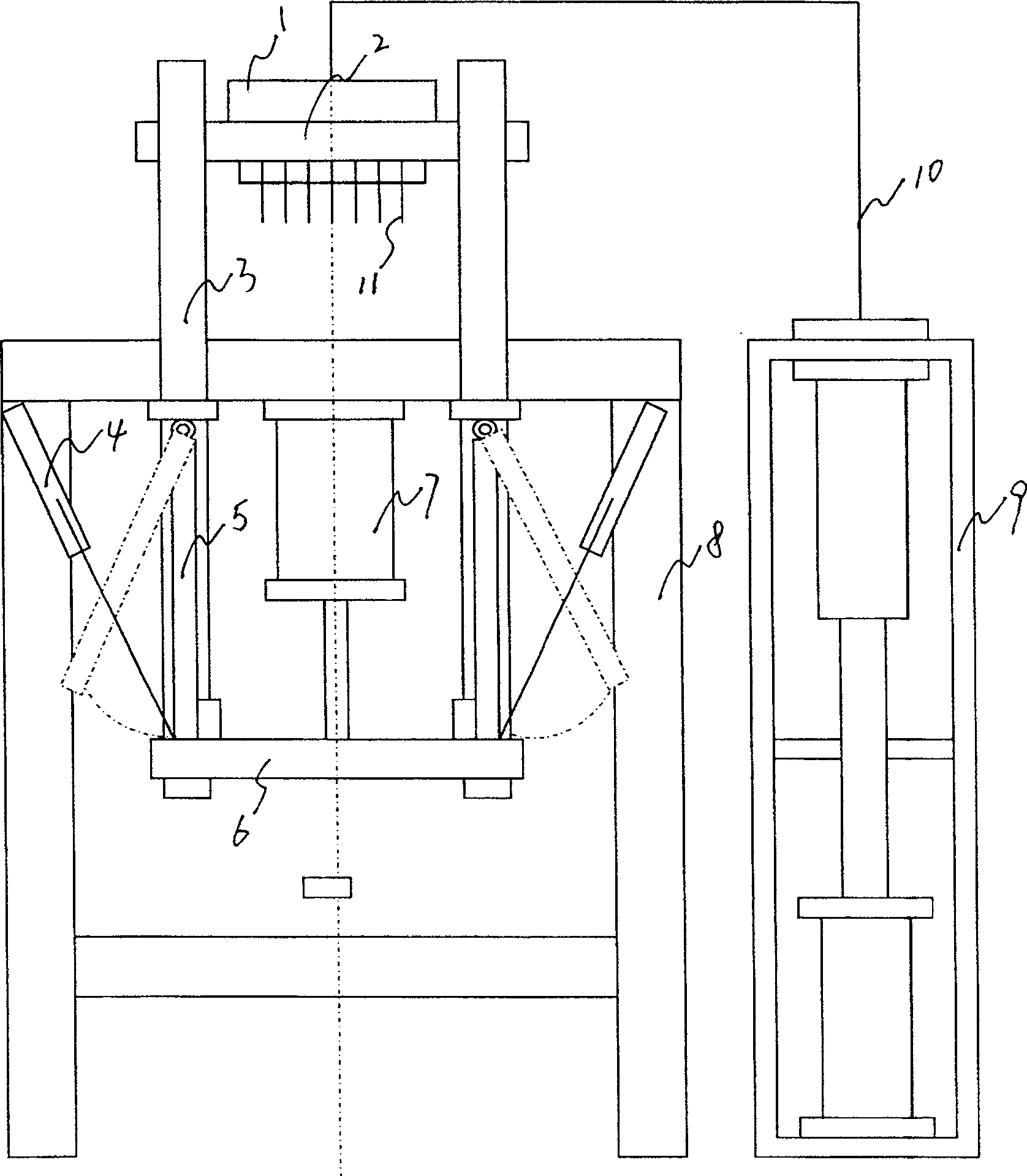

[0009] Example 1: Refer to the attached figure 1 . Special press for industrial detonators, which includes frame 8 and reference attached figure 1 Processed and manufactured according to existing technology. The four uprights 3 refer to the uprights with column sleeves. The four uprights 3 are respectively located (installed on) the side of the frame 8 and the lower ends of the four uprights are connected to the lifting plate 6, and the upper part of the four uprights is connected to the hydraulic compensation head 2. , The hydraulic compensation head 2 is composed of a hydraulic compensator 1 and a plurality of hydraulic plungers 11, and the plurality of hydraulic plungers 11 are respectively located in the hydraulic lifting cavity of the hydraulic compensator 1 and extend together in the state of hydraulic pressure. Retract with the hydraulic pressure unloaded. The pressurization (loading) or unloading of the hydraulic compensation head 2 depends on the gas-liquid pressurization...

Embodiment 2

[0010] Example 2: On the basis of Example 1, the method of compressing detonator explosives by a special industrial detonator press. After the turnover die with a fire detonator is sent to the positioning seat of the turnover die of the industrial detonator press, the piston in the main cylinder pushes The lifting plate moves down, and the multiple plungers in the hydraulic compensation head descend from the top dead center to the inner surface of the tube shell. The self-locking rod in the self-locking mechanism is pushed to the vertical state by the cylinder and the four-column lifting mechanism is locked. The gas-liquid pressurization mechanism pressurizes the hydraulic compensation head and directly acts on the multiple plungers in the hydraulic compensation head. The plunger completes the compression of the explosive loaded in the detonator. When the compression reaches the set value, The gas-liquid pressurizing mechanism is unloaded, the self-locking mechanism unlocks the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com