Permanent magnetism electromagnetic blending magnet design method of electromagnetic type maglev train and structure

A maglev train and electromagnetic hybrid technology, applied in electric vehicles, electric traction, vehicle components, etc., can solve the problems of insufficient carrying capacity of the device, unable to meet the requirements of engineering applications, etc., to reduce the maximum ampere-turn, the adjustment range is large, the The effect of the requirement of orbital accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

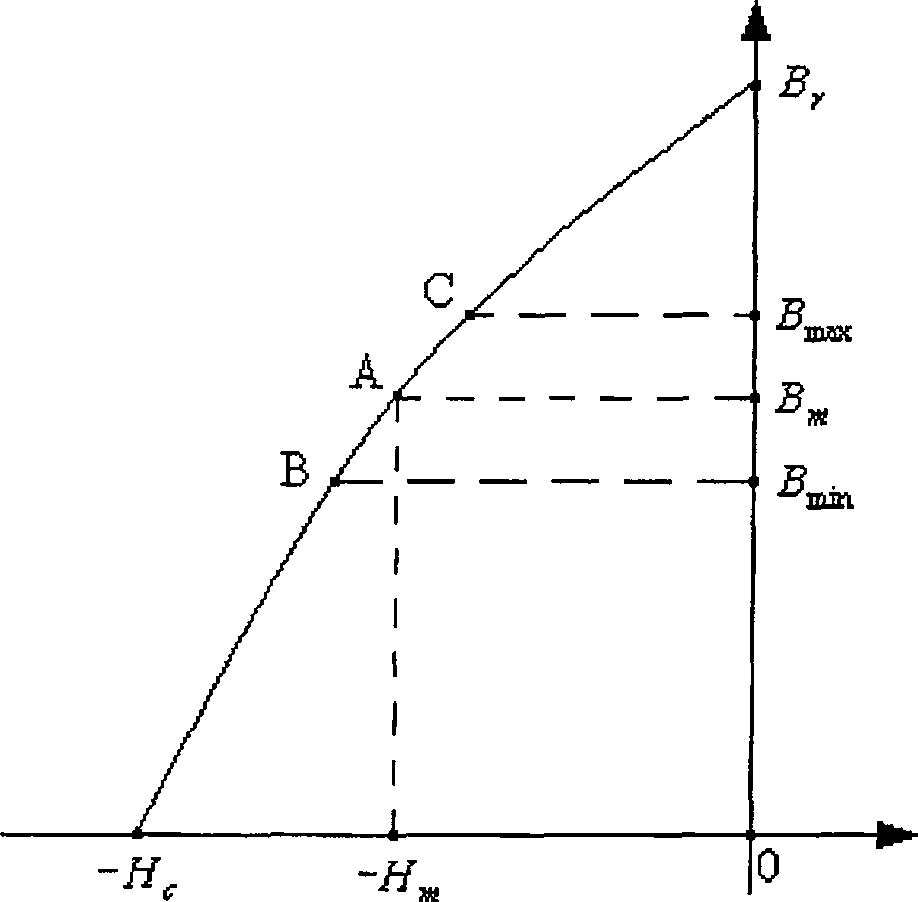

[0024] In the field of permanent magnet research, the key to designing permanent electromagnetic hybrid magnets is to select the working point of the permanent magnet reasonably. As we all know, the B-H curve of a permanent magnet is determined by the material, which reflects the changing trend and range of the working point of the permanent magnet. Such as figure 1 shown, where B m is the magnetic density at the working point, H m is the magnetic field strength at the working point, B r is the residual magnetism of the permanent magnet, H c is the coercive force of the permanent magnet. If the working point of the permanent magnet is too high or too low, its variation range will be very small, which directly leads to a very limited variation range of the levitation force provided by the hybrid magnet, making the dynamic adjustment process of the maglev train more difficult, or even unable to achieve stability suspended.

[0025] According to the magnetic flux continuity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com