Automatic control device for electron-beam evaporation rate and control method thereof

An electron beam evaporation and evaporation rate technology, applied in vacuum evaporation plating, ion implantation plating, metal material coating process, etc., can solve the problems of slow reaction, poor adjustment accuracy, unable to meet the requirements of fast, accurate and stable adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

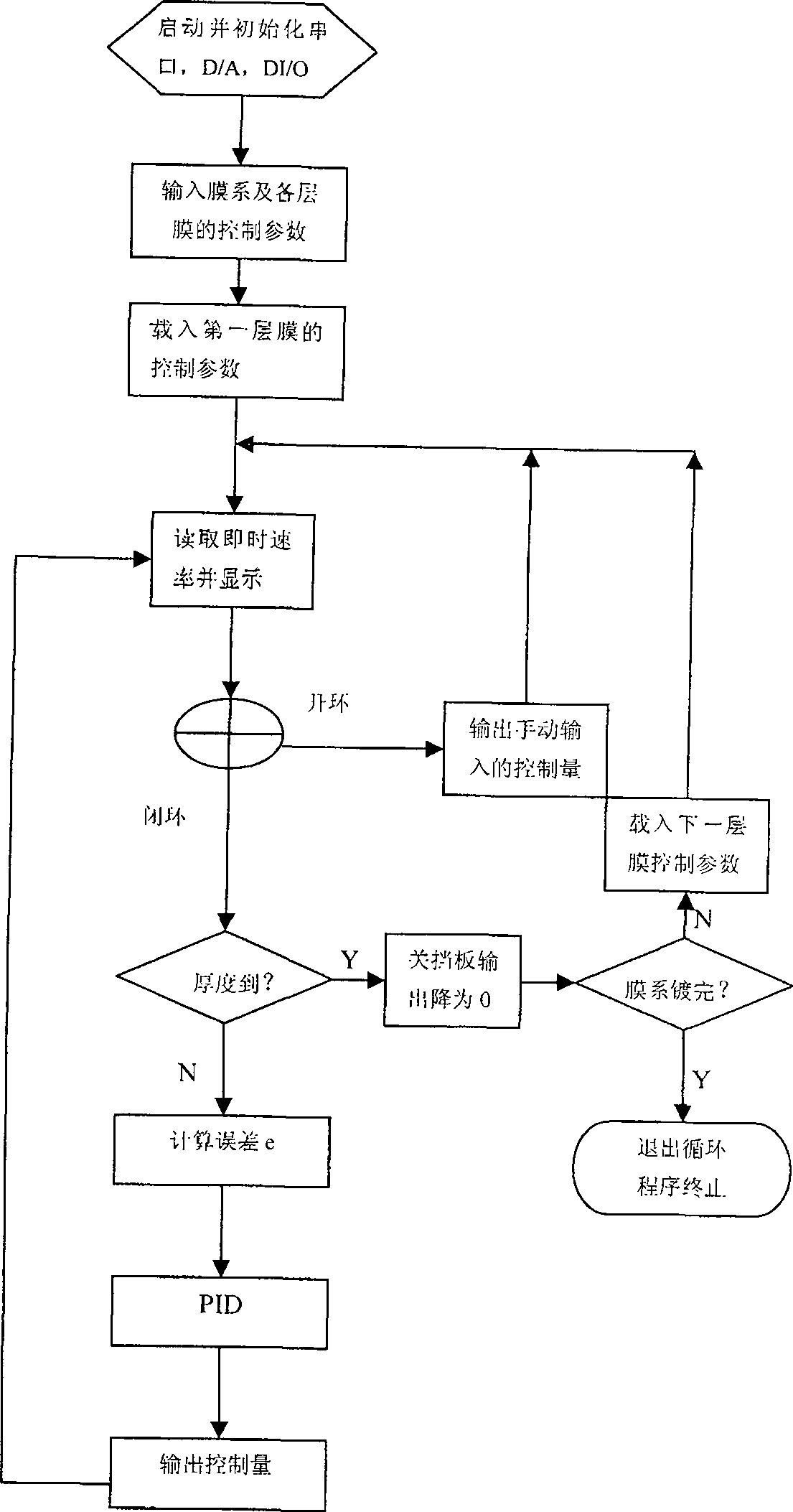

[0032] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention should not be limited thereto.

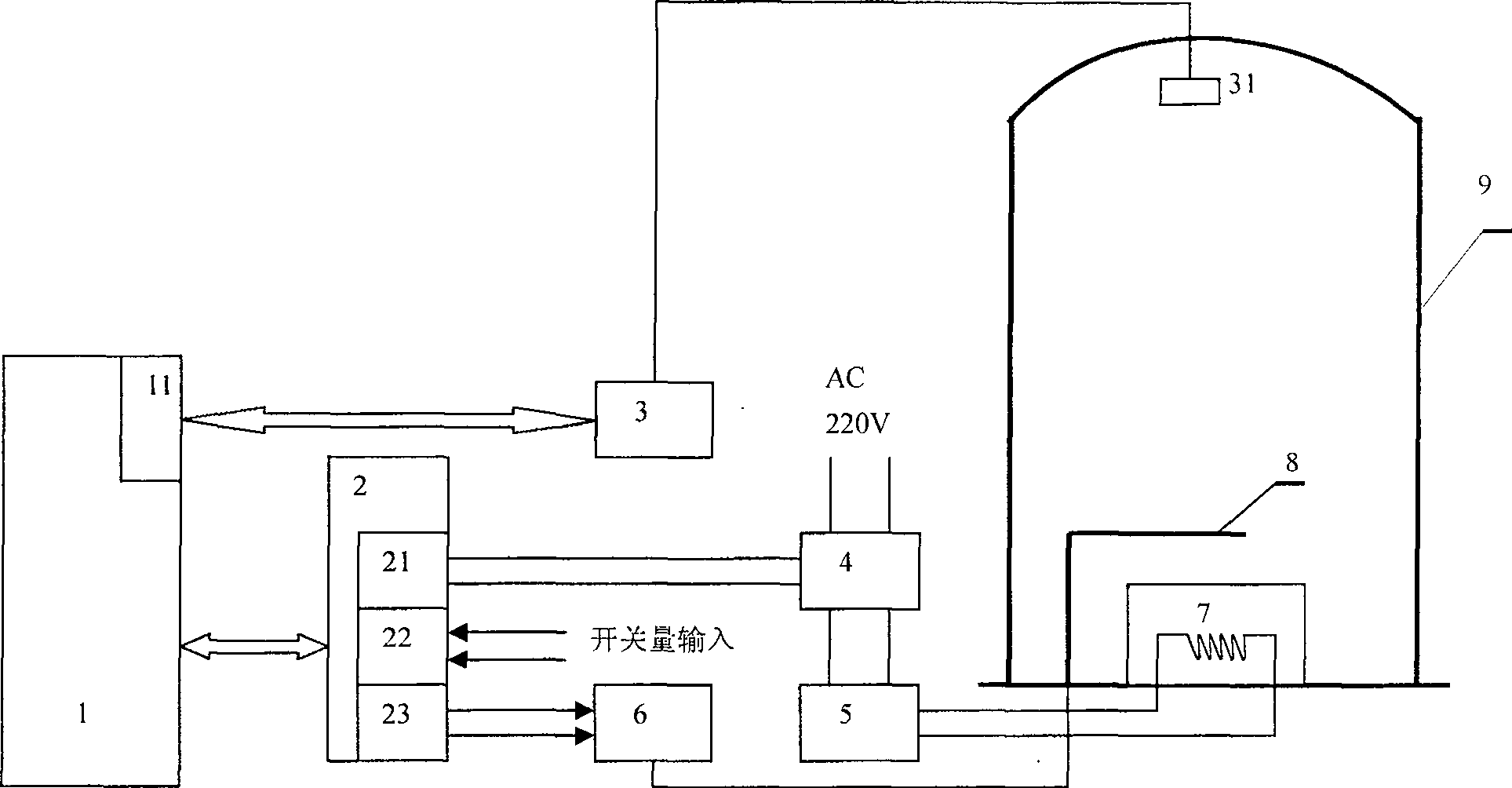

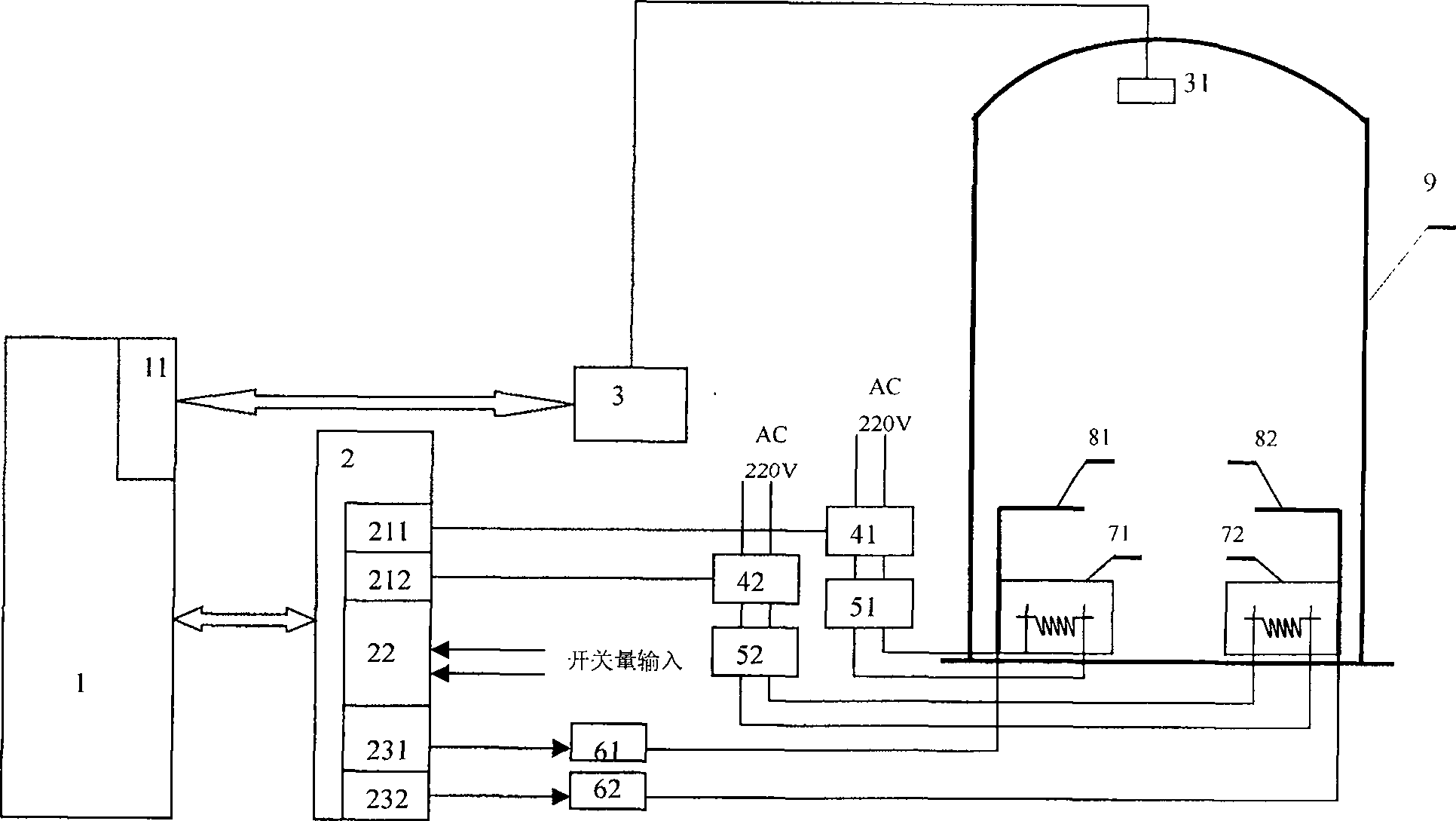

[0033] Please see first figure 1 , figure 1 It is a schematic diagram of the overall structure of Embodiment 1 of the automatic control device for electron gun evaporation rate of the present invention. As can be seen from the figure, the electronic gun evaporation rate automatic control device of the present invention includes:

[0034] An evaporation rate detector 3, the crystal oscillator probe 31 of the evaporation rate detector 3 is placed in the vacuum chamber 9 of the electron beam evaporation coating machine to detect the instant electron beam evaporation rate;

[0035] Data acquisition card 2;

[0036] The electronic gun filament voltage regulating mechanism is composed of the digital-to-analog converter 21 of the data acquisition card 2, the thyristor intelligent voltage regulation module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com