Eccentric device for vortex compressor

A technology of scroll compressors and eccentric devices, applied in the direction of rotary piston machinery, parts of pumping devices for elastic fluids, rotary piston pumps, etc., can solve the problems of complex assembly engineering and increased production costs, etc. Achieve the effects of simplifying assembly engineering, saving production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

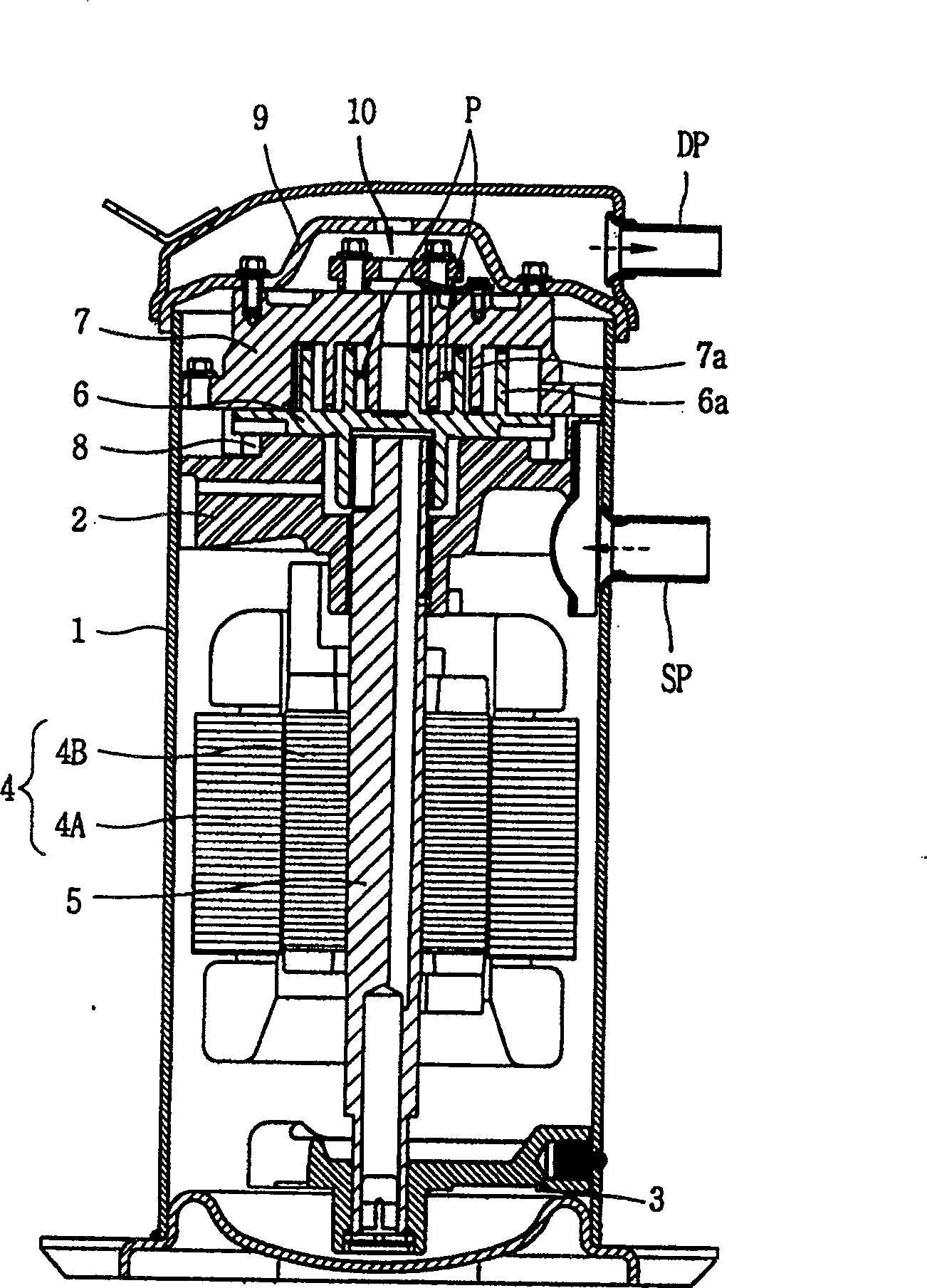

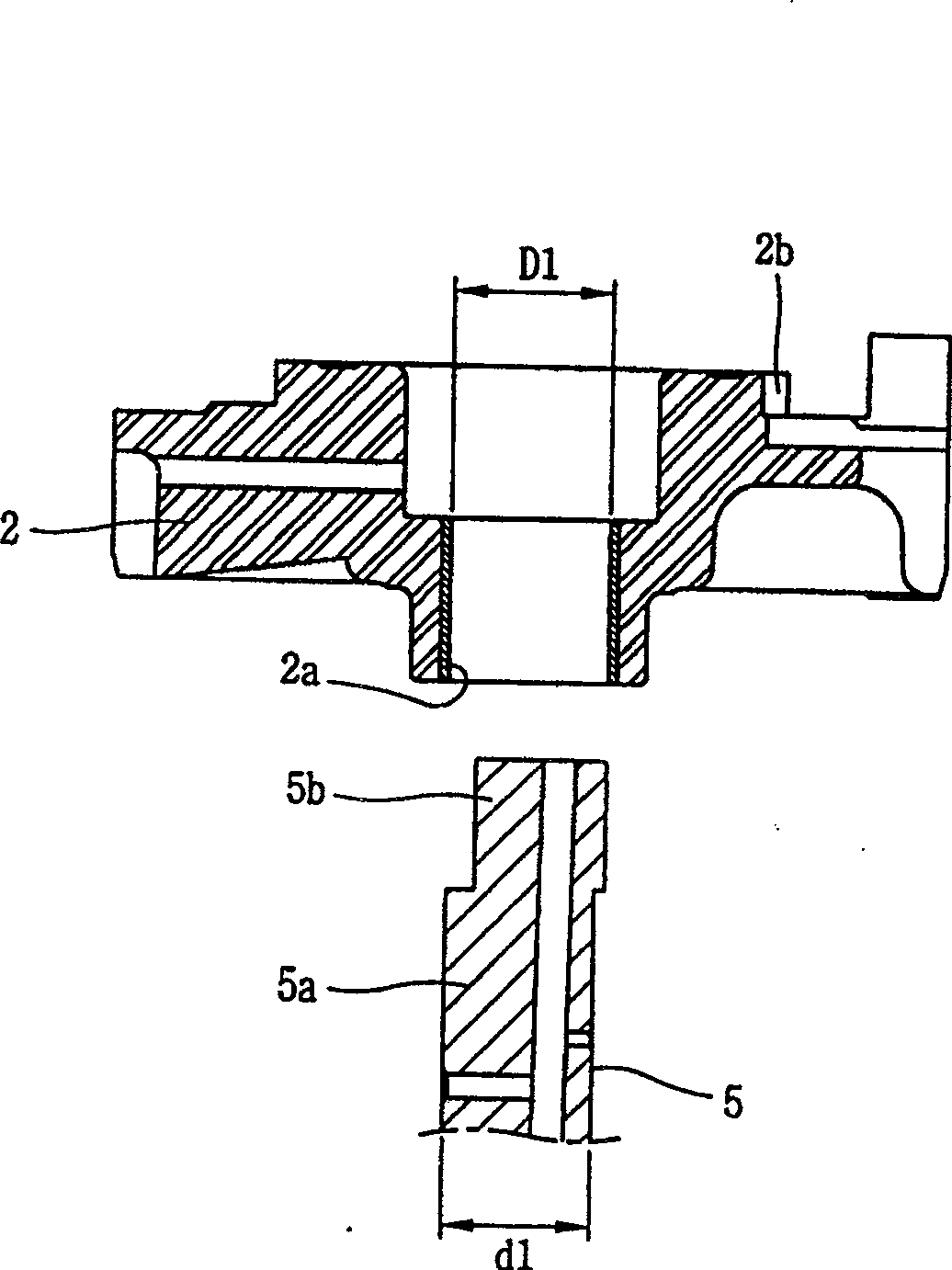

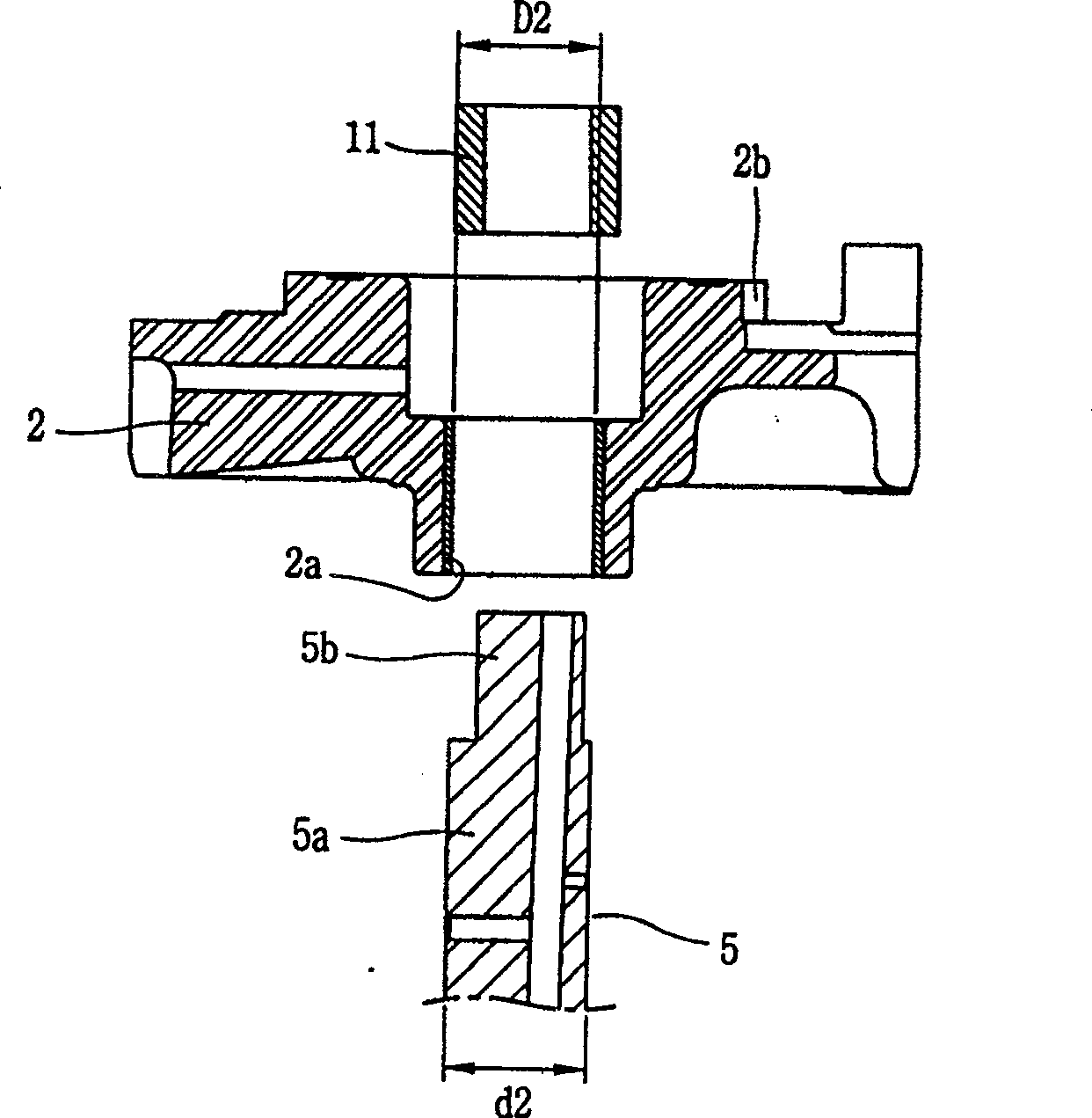

[0027] Such as figure 1 , 4 , 5 and 6, the scroll compressor designed by the present invention includes: the main frame 110 fixed in the casing 1; combined with the rotor 4B of the drive motor 4, driven by the support of the main frame 110 in the radial direction Shaft 120; eccentrically arranged on the upper end of the drive shaft 120, the power of the drive motor 4 is transmitted to the fixed bushing 130 in the scroll rotor 6 forming a pair of compression chambers P together with the scroll stator 7; and the drive shaft 120 A fixed pin 140 that prevents the rotation of the fixed bush 130 is interposed coincidently with the critical line of the fixed bush 130 .

[0028] The main frame 110 adopts a disc-shaped structure, and a shaft hole 111 having the same diameter D as the diameter d of the rotating structure 121 is provided at its central position to radially support the rotating structure 121 of the inserted rotatable drive shaft 120, A bolt hole 112 for a bolt (not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com