Process and apparatus for coating with a liquid

A device and coating technology, which can be applied to devices, coatings, and electro-solid devices that apply liquid to surfaces, and can solve problems such as slowness, contamination of film layers, and increased manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

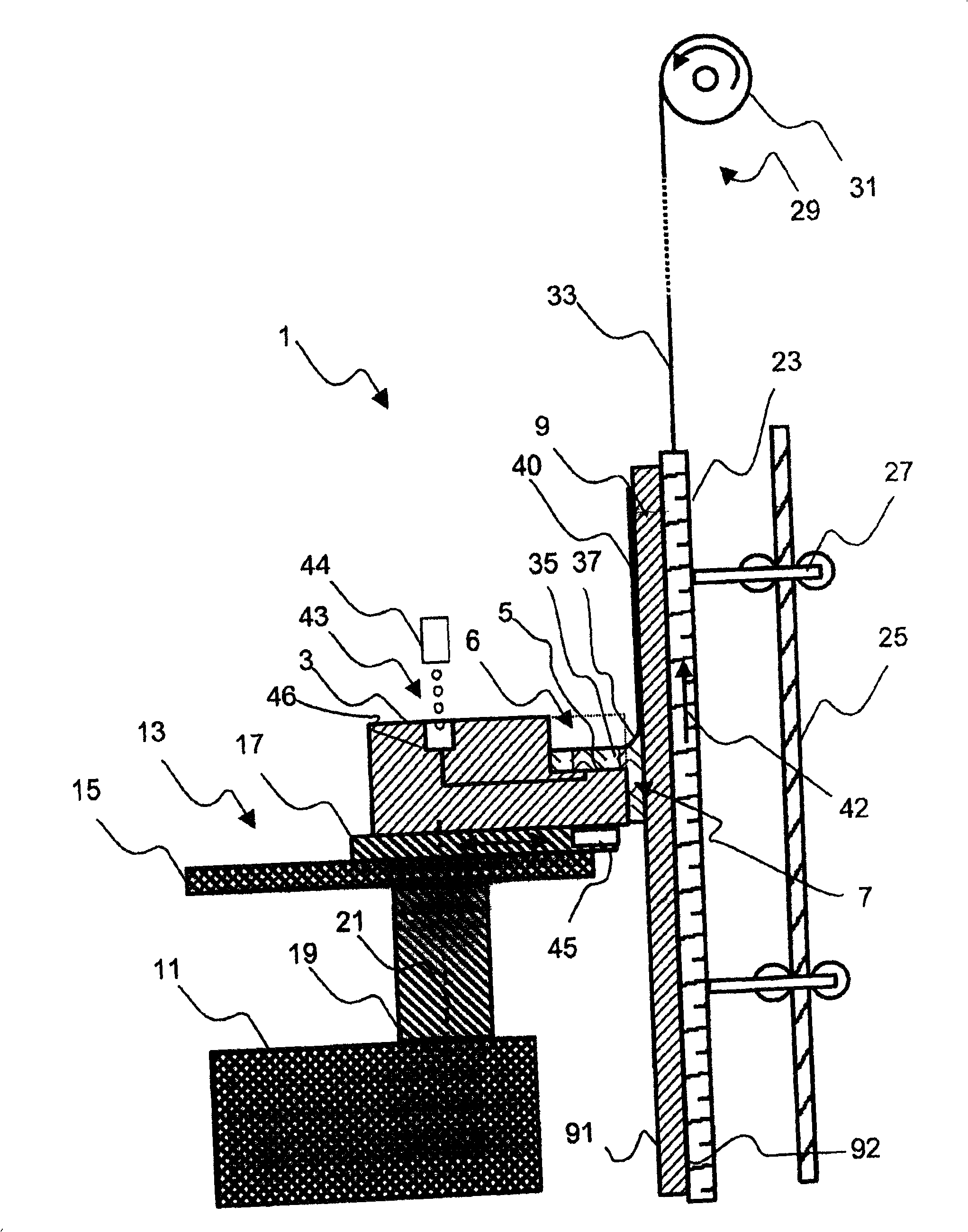

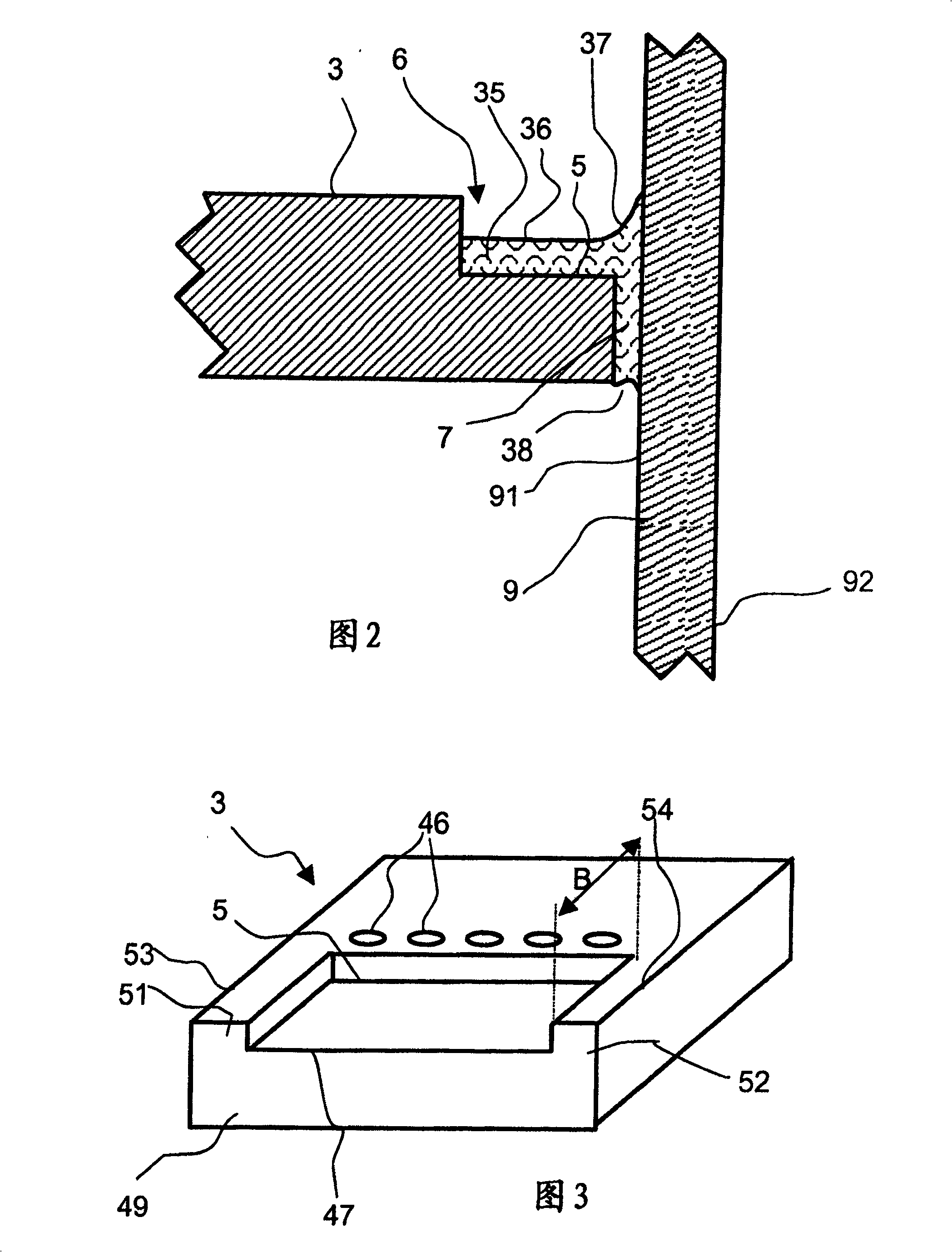

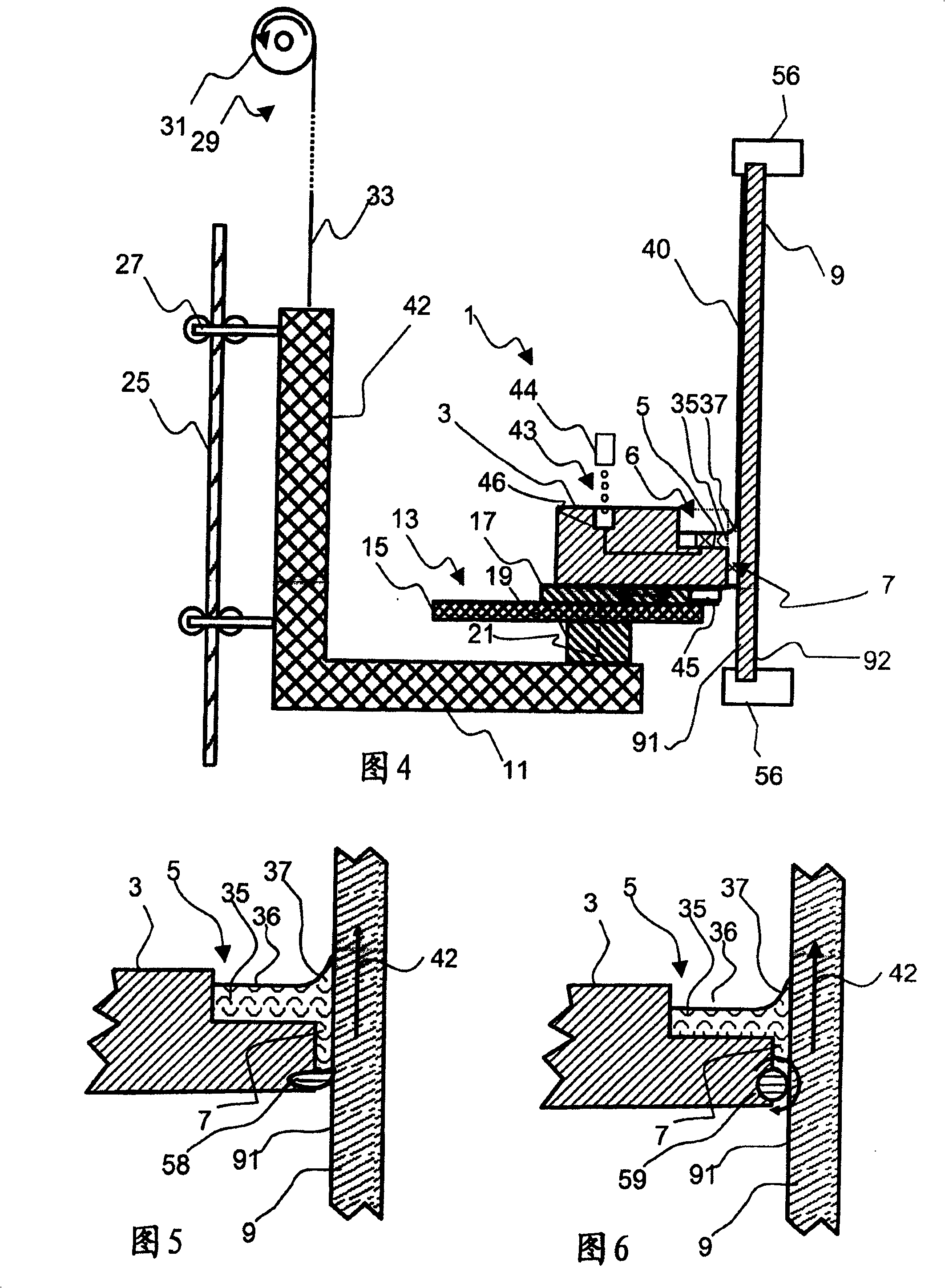

[0072] Refer to the following content figure 1 and figure 2 . figure 1 is a diagrammatic view of an exemplary embodiment of an apparatus for liquid coating a substrate, which apparatus is generally indicated by the numeral 1 . This device comprises a coating head 3 in the form of a channel block with a cutout in the form of a channel 5 which is open laterally and at the top.

[0073] figure 2 is shown in figure 1 An enlarged cross-sectional view of the coating head 3 and the substrate 9 arranged in front of the coating head 3.

[0074] Examples of suitable materials for the applicator head 3 are stainless steel, in particular V4A steel, or tool steel. Glass, glass ceramics, plastics, or composite materials comprising these materials can also be used as material for the applicator head.

[0075] This device also includes a holding frame 23 for a planar base 9 facing the transverse opening of the channel and having two sides 91 , 92 . For OLED lighting elements, such a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap