Hybrid drive apparatus

A technology of hybrid drive and variable speed device, which is applied in the direction of transmission device, power device, electric power device, etc., to achieve the effects of easy manufacturing, prolonging life and reasonable power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

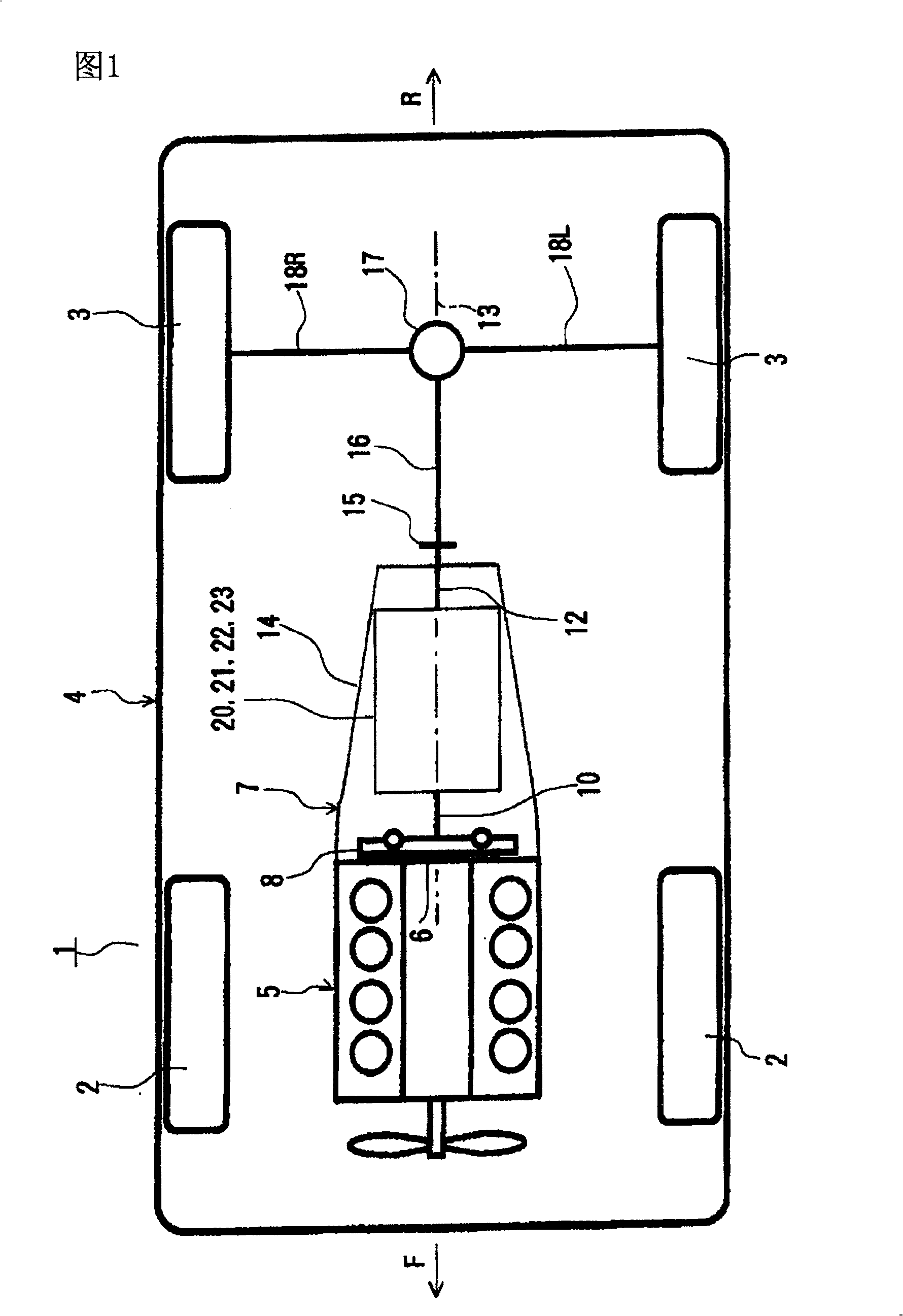

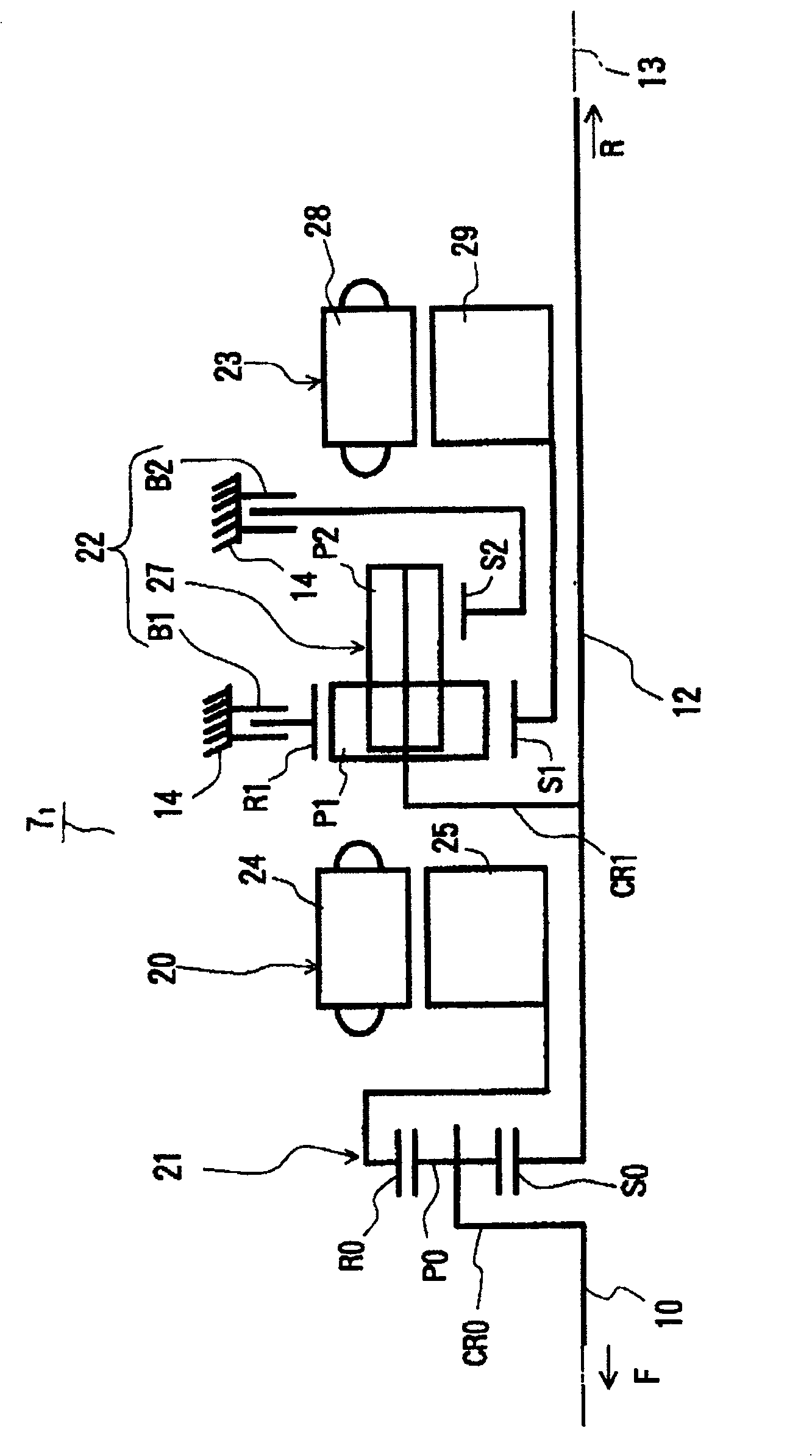

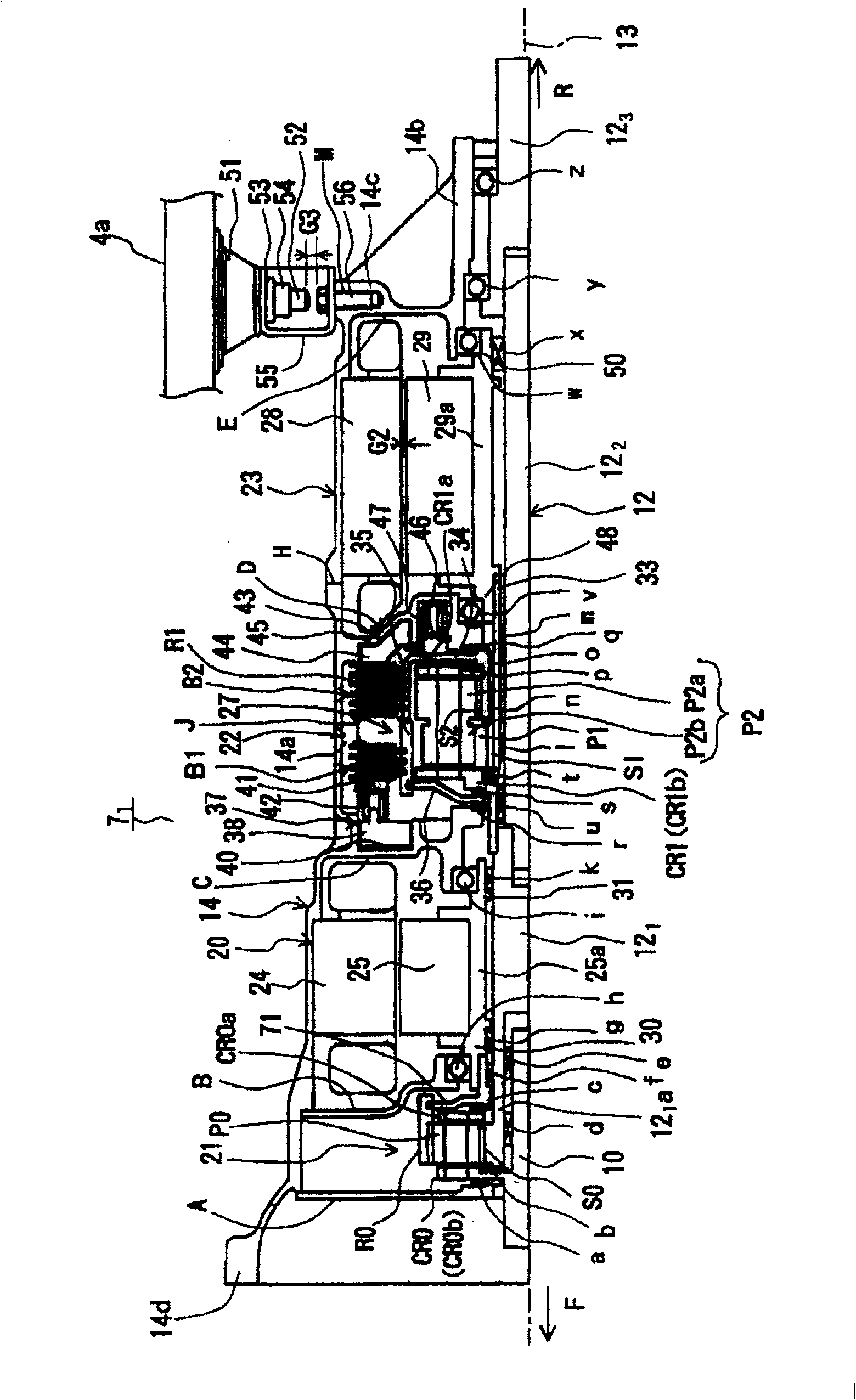

[0063] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 An example of an automobile according to the present invention, that is, an automobile 1 equipped with a hybrid drive device according to the present invention is shown. The automobile 1 shown in this figure is a FR (front engine, rear wheel drive) type automobile, and this figure is a plan view typically showing its schematic configuration. In addition, in an actual automobile, the arrow F direction in the figure indicates the front side, and the arrow R direction indicates the rear side.

[0064] The automobile 1 shown in this figure has a vehicle body 4 supported by left and right front wheels 2, 2 and left and right rear wheels 3, 3 serving as drive wheels. On the front portion of the vehicle body 4 , the internal combustion engine 5 is mounted via rubber fittings (not shown) with its crankshaft 6 oriented in the front-rear direction. In addition, in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com