Industrial ultrapure water preparation process

A preparation process, ultra-pure water technology, applied in the direction of general water supply saving, degassed water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of low removal rate, no removal of bicarbonate, and can not meet the requirements of industrial applications and other issues to achieve the effect of low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

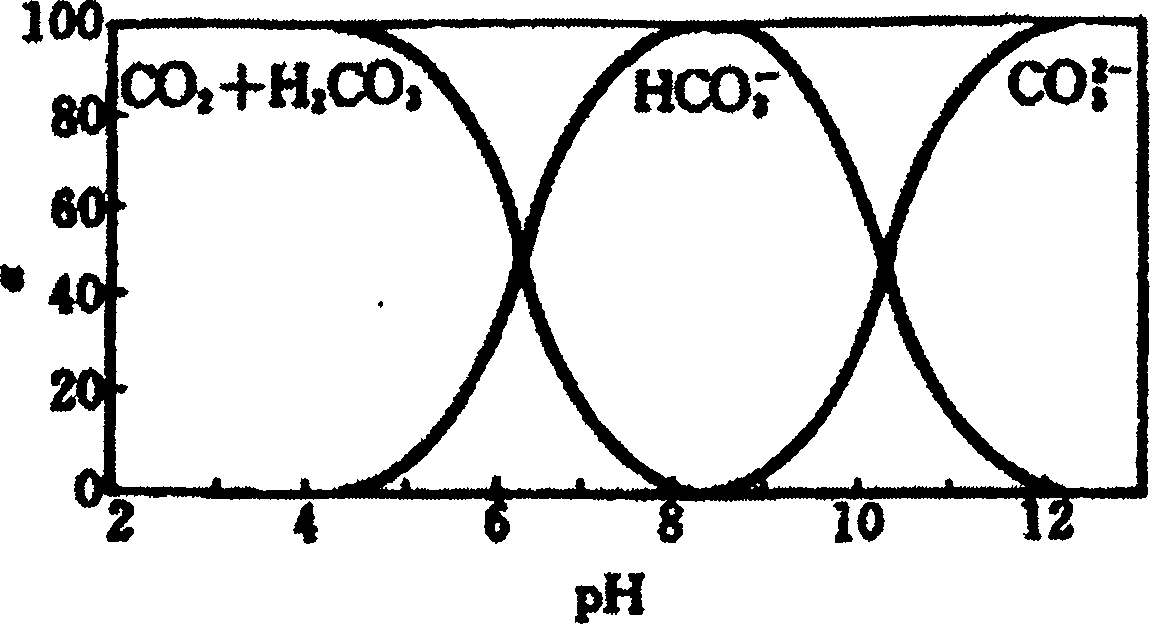

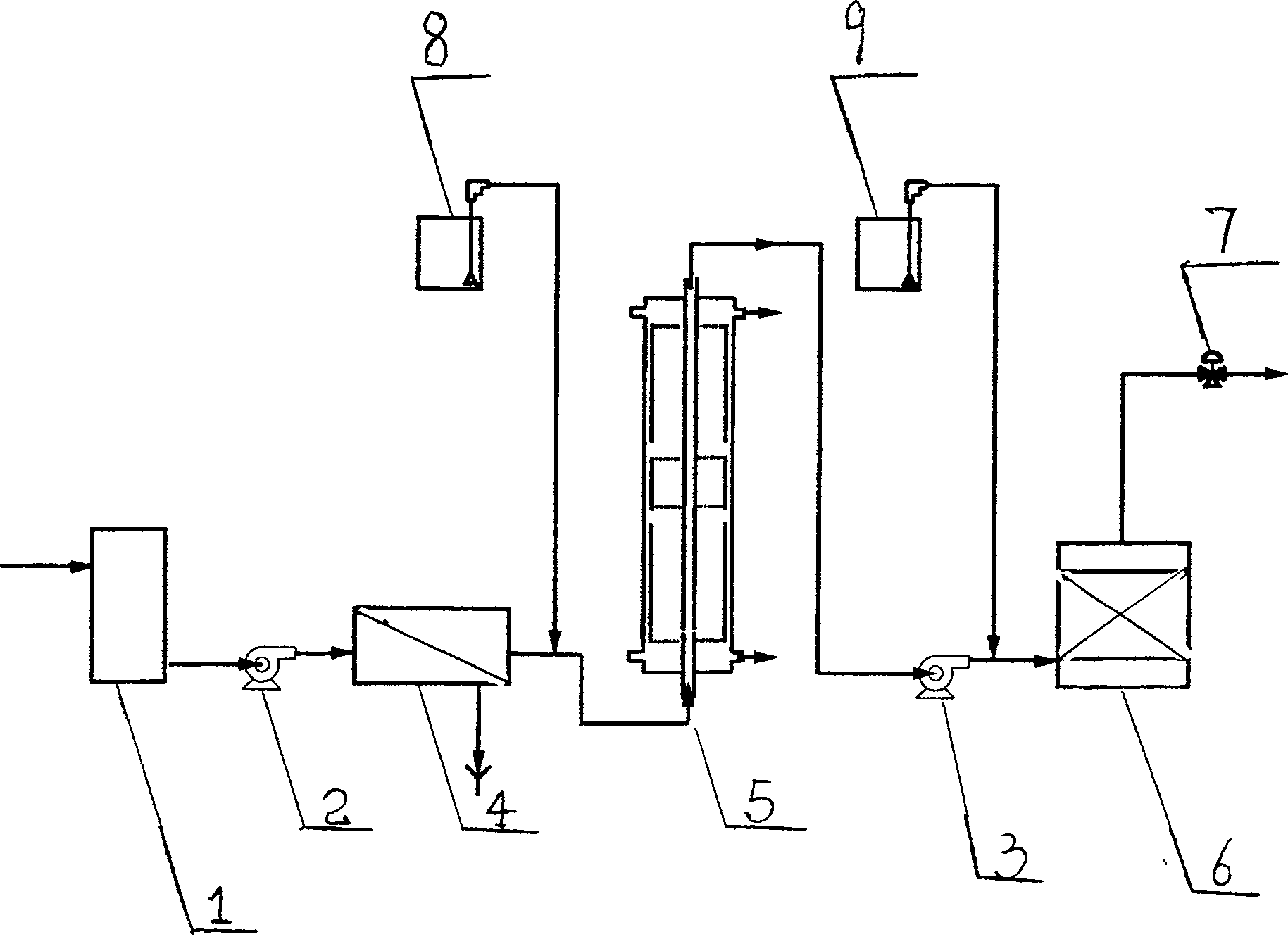

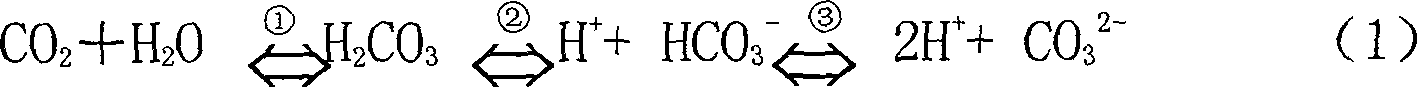

[0042] Example 1: After the raw water is pretreated by the pretreatment facility 1, it is pressurized by the high-pressure pump 2 and supplied to the reverse osmosis membrane group 4 through the pipeline to remove dissolved salts in the water, and at the same time remove some macromolecules and small particles that were not removed in the previous stage Wait. Its function is to pre-demineralize the pre-treated produced water. The hydrochloric acid dosing system 8 adds hydrochloric acid to the pretreated water that has been desalted by the reverse osmosis membrane, so that the pH value of the pretreated water is 6. The purpose of adding hydrochloric acid is to convert bicarbonate and carbonate into carbonic acid by adding acid , the pretreated water passes through the degassing device 5 to remove carbon dioxide. After passing through the degassing device 5, most of the carbon dioxide gas in the water is removed, and the remaining carbon dioxide gas dissolved in water, that is,...

Embodiment 2

[0043] Example 2: After the raw water is pretreated by the pretreatment facility 1, it is pressurized by the high-pressure pump 2 and supplied to the reverse osmosis membrane group 4 through the pipeline to remove dissolved salts in the water, and at the same time remove some macromolecules and small particles that were not removed in the previous stage Wait. Its function is to pre-demineralize the pre-treated produced water. The hydrochloric acid dosing system 8 adds hydrochloric acid to the pretreated water that has been pre-desalted by the reverse osmosis membrane, so that the pH value of the pretreated water is 5. The purpose of adding hydrochloric acid is to convert bicarbonate and carbonate into carbonic acid by adding acid , the pretreated water passes through the degassing device 5 to remove carbon dioxide. After passing through the degassing device 5, most of the carbon dioxide gas in the water is removed, and the remaining carbon dioxide gas dissolved in water, that...

Embodiment 3

[0044] Example 3: After the raw water is pretreated by the pretreatment facility 1, it is pressurized by the high-pressure pump 2 and supplied to the reverse osmosis membrane group 4 through the pipeline to remove dissolved salts in the water, and at the same time remove some macromolecules and small particles that were not removed in the previous stage Wait. Its function is to pre-demineralize the pre-treated produced water. The hydrochloric acid dosing system 8 adds hydrochloric acid to the pretreated water that has been pre-desalted by the reverse osmosis membrane, so that the pH value of the pretreated water is 4. The purpose of adding hydrochloric acid is to convert bicarbonate and carbonate into carbonic acid by adding acid , the pretreated water passes through the degassing device 5 to remove carbon dioxide. After passing through the degassing device 5, most of the carbon dioxide gas in the water is removed, and the remaining carbon dioxide gas dissolved in water, that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com