Fixed width traversing device of rolling cut type bilateral shear and mobile shear

A technology of traversing device and double-side shearing, which is applied to the attachment of shearing machines, shearing devices, and shearing machine equipment, etc., which can solve problems such as difficulties in manufacturing and assembly, inability to eliminate meshing gaps, and influence of fixed width accuracy, etc., to achieve Easy adjustment and disassembly, low manufacturing cost, high precision of fixed width control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

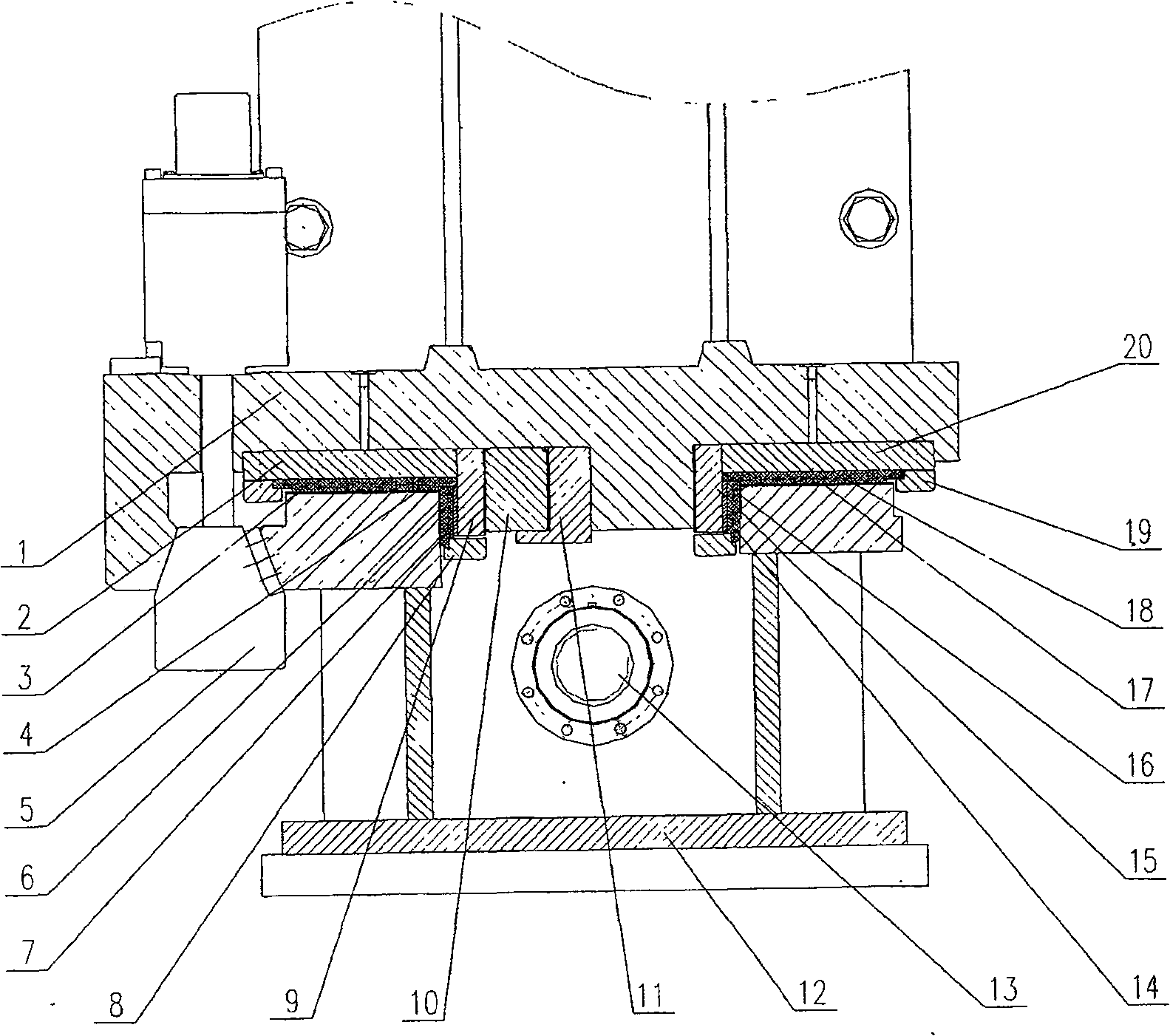

[0009] With reference to the accompanying drawings, the whole device consists of a frame 1, a support plate 2, a lower plate 3, a lower steel belt 4, a locking plate 5, a side steel belt 6, a side slide plate 7, a pressing plate 8, a side support plate 9, and an adjustment wedge. 10. Adjusting wedge 11, track base 12, transmission lead screw 13, side slide plate 14, side support plate 15, side steel belt 16, lower steel belt 17, lower slide plate 18, pressing plate 19, support plate 20, the lower The steel belt 4 is installed on the track base 12, and the steel belt is tightened by a tensioning mechanism, the side steel belt 6 is installed on the side of the track base 12, and the steel belt is tightened by the tensioning mechanism, and the lower plate 3 is embedded in the support The plate 2 is pressed together with the pressing plate 19, the side slide plate 7 is embedded in the side supporting plate 9 and pressed with the pressing plate 8, and then the supporting plate 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com