Wood composite floor and production method therefor

A technology of solid wood composite floor and wood square, applied in the direction of manufacturing tools, wood layer products, chemical instruments and methods, etc., can solve the problems of rising indoor environmental pollution, affecting floor installation, rough groove and mouth surface, etc., to protect natural forestry Resources, saving wood resources, the effect of small deformation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

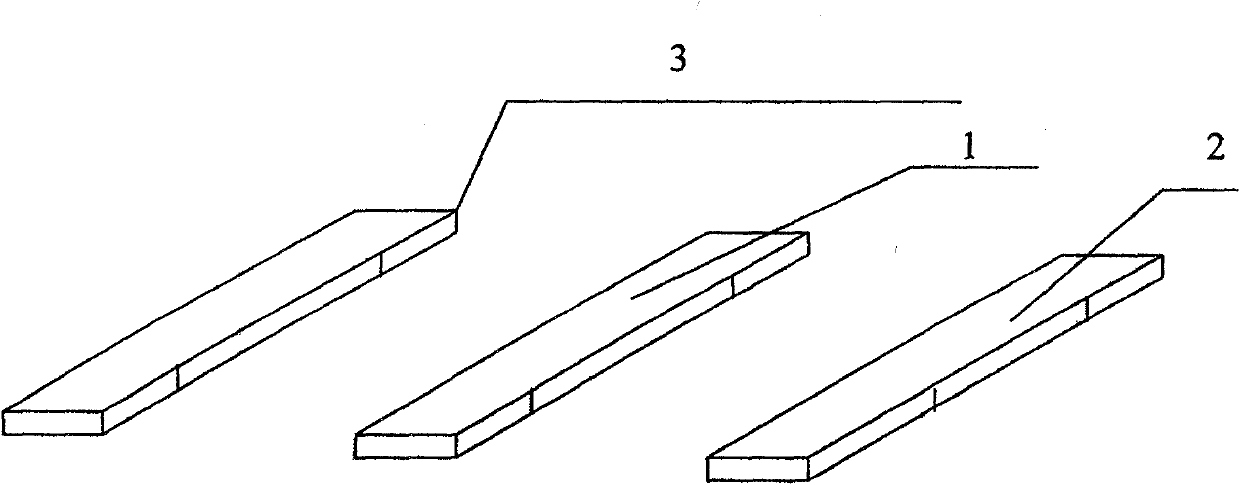

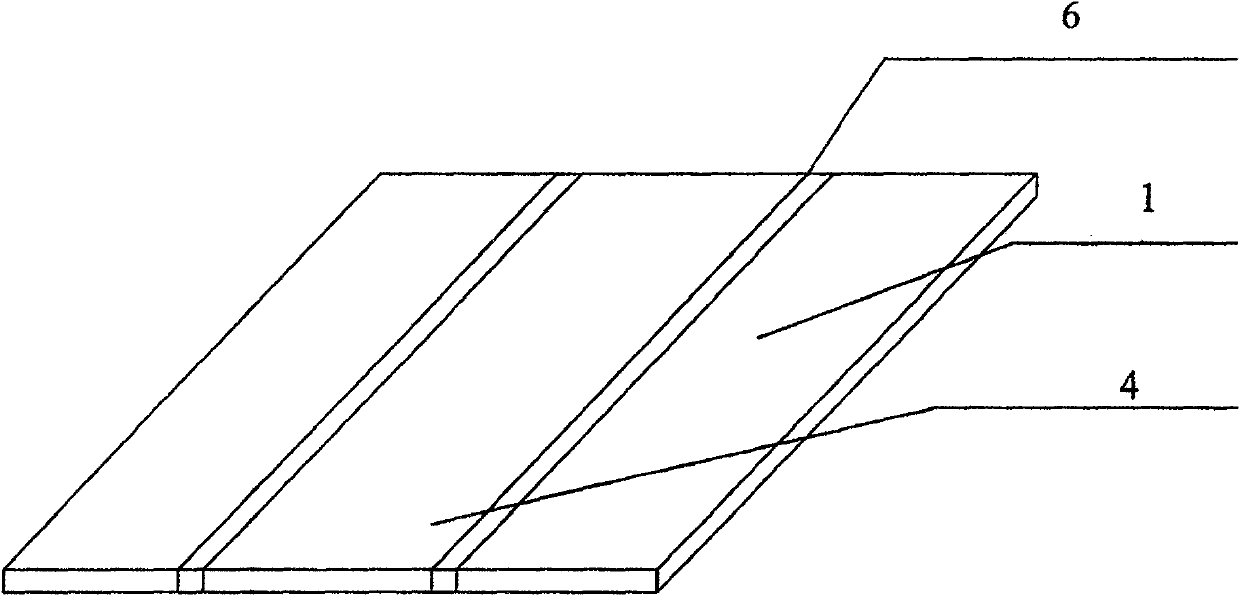

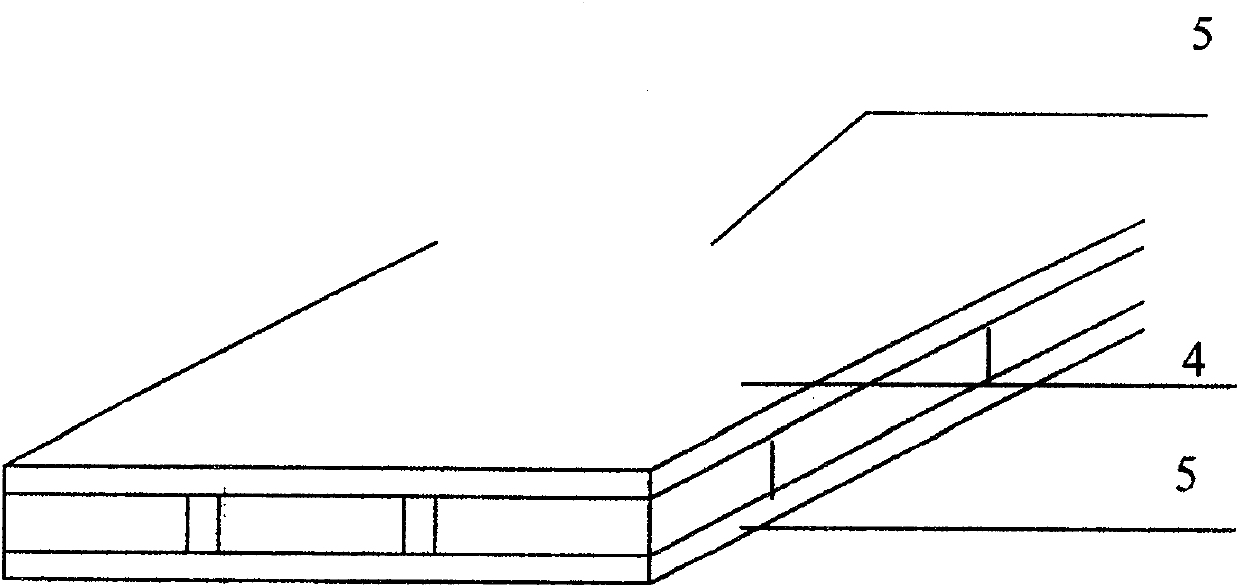

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings: the present invention is at least made of three layers of plates through a structural composite process, and the intermediate substrate layer is mainly a long wooden square block 1 made by a finger-joint process. composition, see attached figure 1 As shown, the so-called finger-joint processing technology refers to: the wood is processed into a block 2, and then the front and back are connected successively, and it is covered with a finger-joint veneer 3 on one side or both sides and spliced with each other to grow a wooden block 1. attached figure 2 As shown, the long wooden blocks 1 are spliced adjacently one by one to form a base material blank 4, and at least one layer of wood veneers 5 with different fiber directions are compounded on the upper and lower sides of the base material blank 4 to form type structure. During the splicing process, the base materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com