Method for demagging from phosphate ore

A technology for phosphate rock and pulp, applied in the field of removing magnesium impurities from phosphate rock, can solve the problems affecting the economic benefits of wet-process phosphoric acid and phosphorus compound fertilizer, high production cost of phosphate rock concentrate products, complicated operation control, etc. The effect of saving agent dosage, high flotation efficiency and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

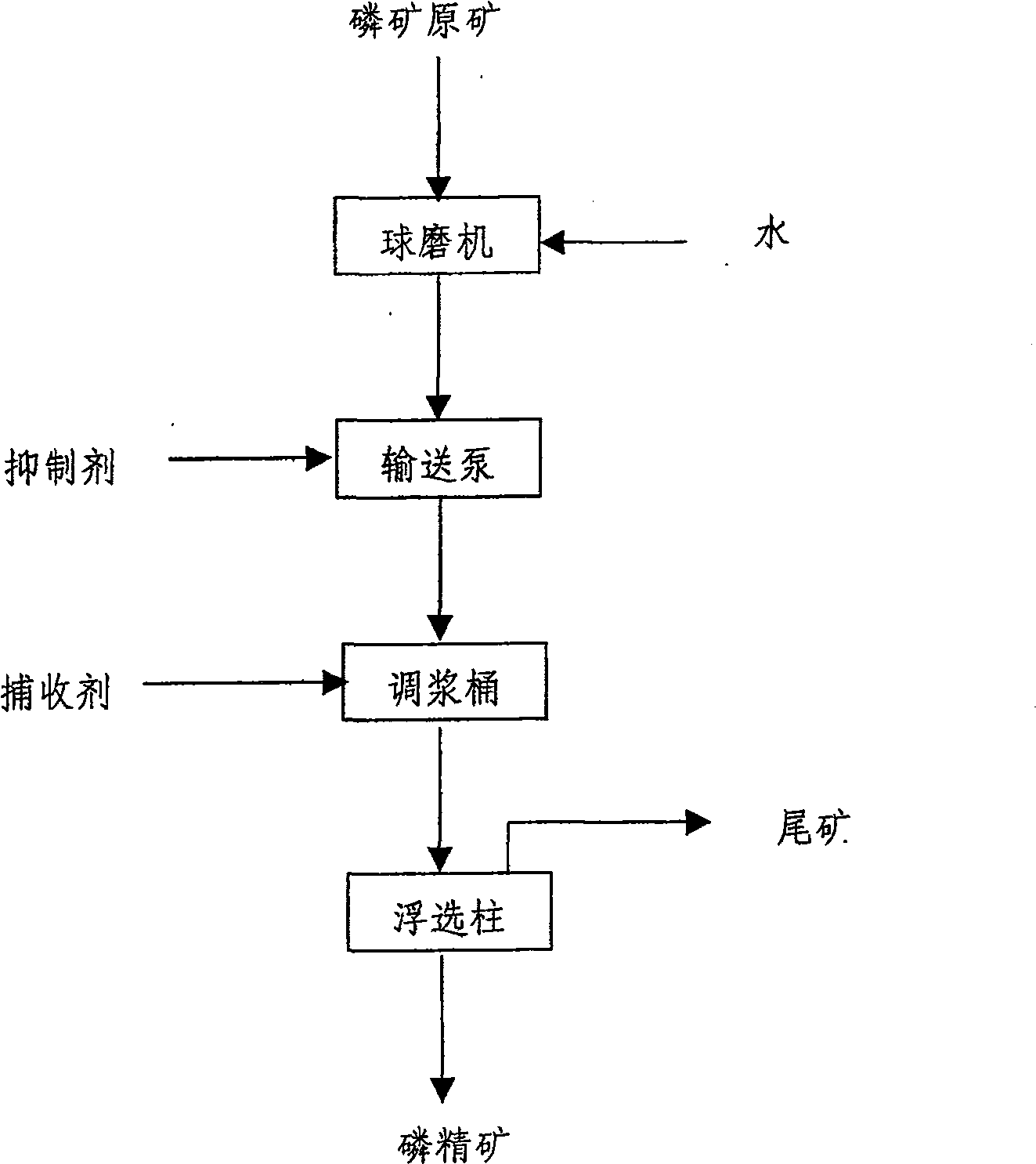

[0025] Mining sample from a mining area in Yunnan, raw ore P 2 o 5 The grade is 26.83%, and the MgO content is 3.91%. Adopt a flotation column, technological process is reverse flotation (see figure 1 ). The grinding fineness is -200 mesh 94%, the grinding concentration is 34%, the flotation temperature is about 20°C, 4.0kg / t of mixed acid and 2.5kg / t of fatty acid collector are added, and the phosphorus concentrate after reverse flotation is P 2 o 5 Grade 30.41%, MgO content 1.37%, P 2 o 5 The recovery rate reached 90.04%, and the MgO removal rate reached 72.17%.

Embodiment 2

[0027] Mine sample is the same as embodiment 1, namely raw ore P 2 o 5 The grade is 26.83%, and the MgO content is 3.91%. Adopt a flotation column, technological process is reverse flotation (see figure 1 ). The grinding fineness is -200 mesh 94%, the grinding concentration is 34%, the flotation temperature is about 20°C, 4.0kg / t of mixed acid and 2.5kg / t of fatty acid collector are added, and the phosphorus concentrate after reverse flotation is P 2 o 5 Grade 31.02%, MgO content 1.18%, P 2 o 5 The recovery rate reaches 94.80%, and the MgO removal rate reaches 76.25%.

Embodiment 3

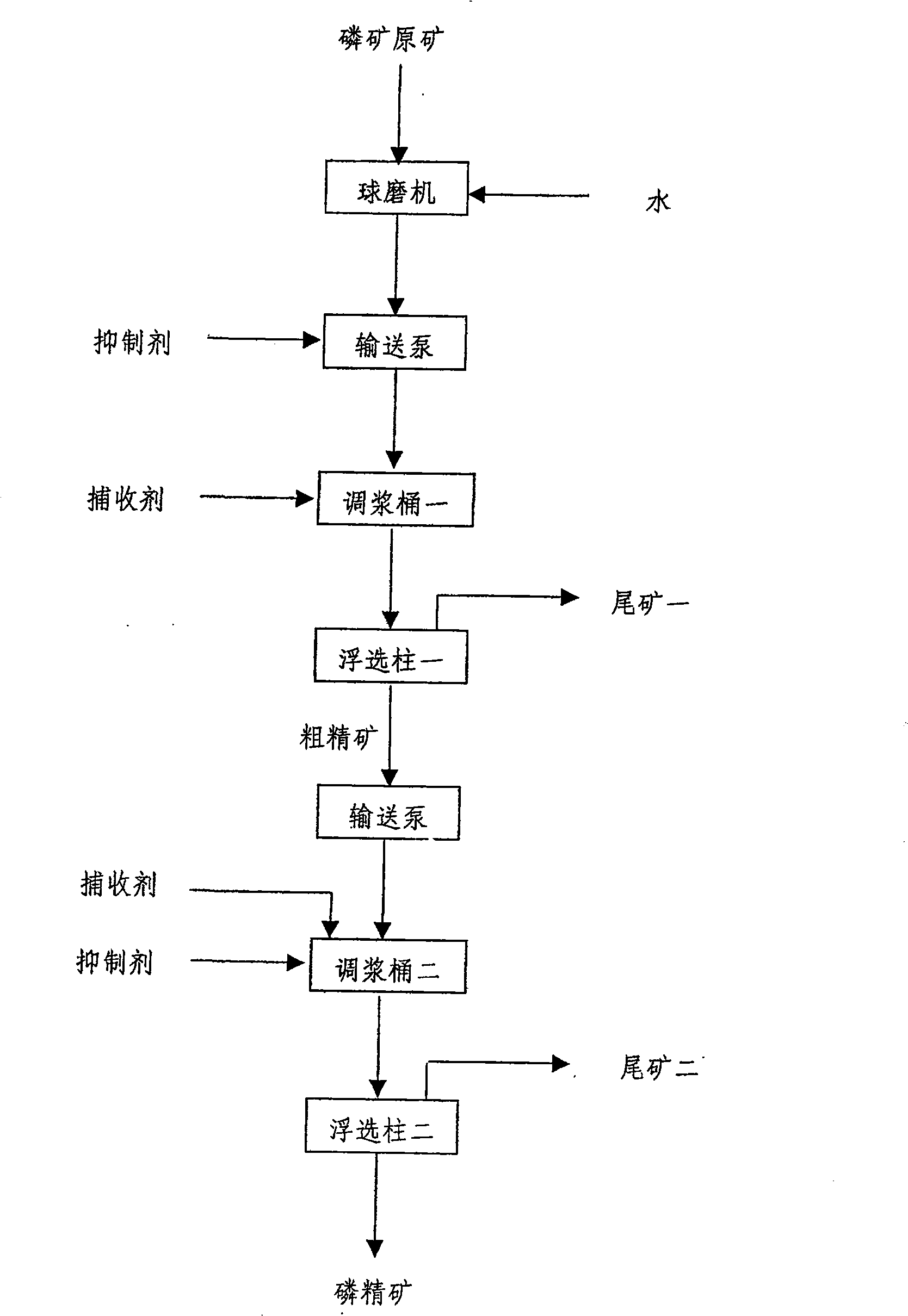

[0029] Mine sample is the same as embodiment 1, namely raw ore P 2 o 5 The grade is 26.83%, and the MgO content is 3.91%. Two flotation columns are used. The process flow is a rough and a fine process (see figure 2 ). The grinding fineness is -200 mesh 94%, the grinding concentration is 34%, the flotation temperature is about 20°C, adding mixed acid 4.0kg / t, collector 2.5kg / t; the parameters of the second stage flotation column are, adding mixed acid 0.5kg / t, fatty acid collector 0.3kg / t, phosphorus concentrate P after reverse flotation 2 o 5 Grade 32.84%, MgO content 0.78%, P 2 o 5 The recovery rate reached 90.69%, and the MgO removal rate reached 85.22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com