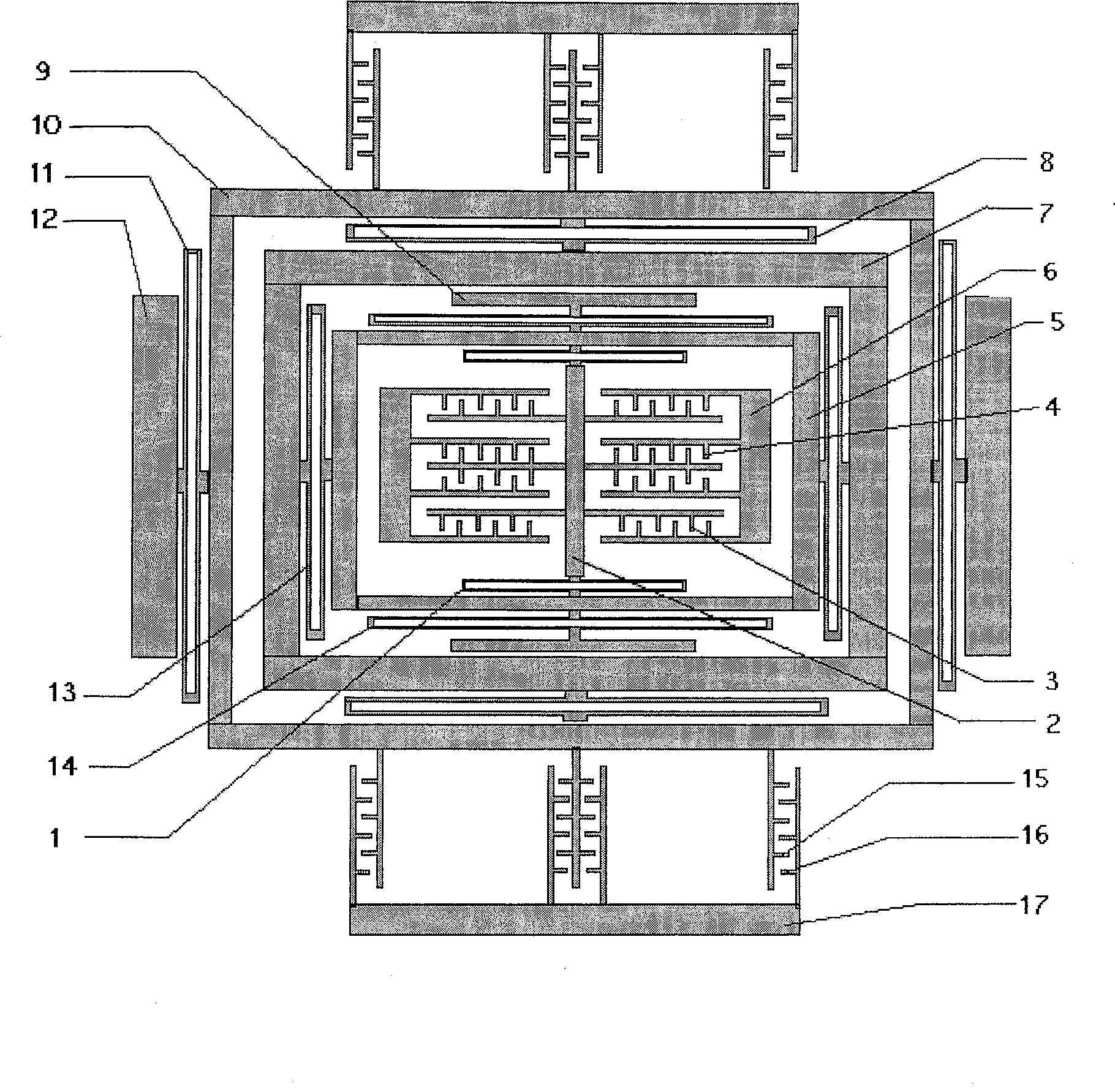

Double freedom double decouple micro mechanical vibration gyrosope senser

A vibrating gyroscope and degrees of freedom technology, used in gyroscope/steering sensing equipment, gyro effect for speed measurement, instruments, etc., can solve the modal coupling error of vibrating gyroscope drive, and is not conducive to improving gyro detection sensitivity, bandwidth and sensitivity Compromise contradictions and other issues to achieve the effect of increasing quality factor, small influence of coupling error, small process and quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The manufacturing process of this invention roughly has following three steps:

[0013] 1. Use ICP dry etching on the back of the silicon to carve out the mesa (8 fixed blocks) required for bonding;

[0014] 2. Bond the bonding mesa etched in step 1 to the glass substrate by electrostatic bonding to form 8 fixed blocks;

[0015] 3. Use ICP to etch the beam, mass, fixed and movable electrode patterns of the sensor on the front side of the silicon, and release the beam, mass and electrode structure.

[0016] The present invention will be described in more detail below in conjunction with accompanying drawing:

[0017] The composition of the dual-degree-of-freedom double-decoupling micromechanical vibrating gyro sensor includes a driving direction bonding block 12 bonded on a glass substrate, a driving fixed electrode bonding block 17, a detecting direction bonding block 9 and a detecting fixed electrode bonding block 6 , the driving direction bonding block is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com