Flexible optoelectronic thin membrane and manufacturing method thereof

A photoelectric thin film and photoelectric medium technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as lack of alignment ability, achieve the effect of improving image brightness and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

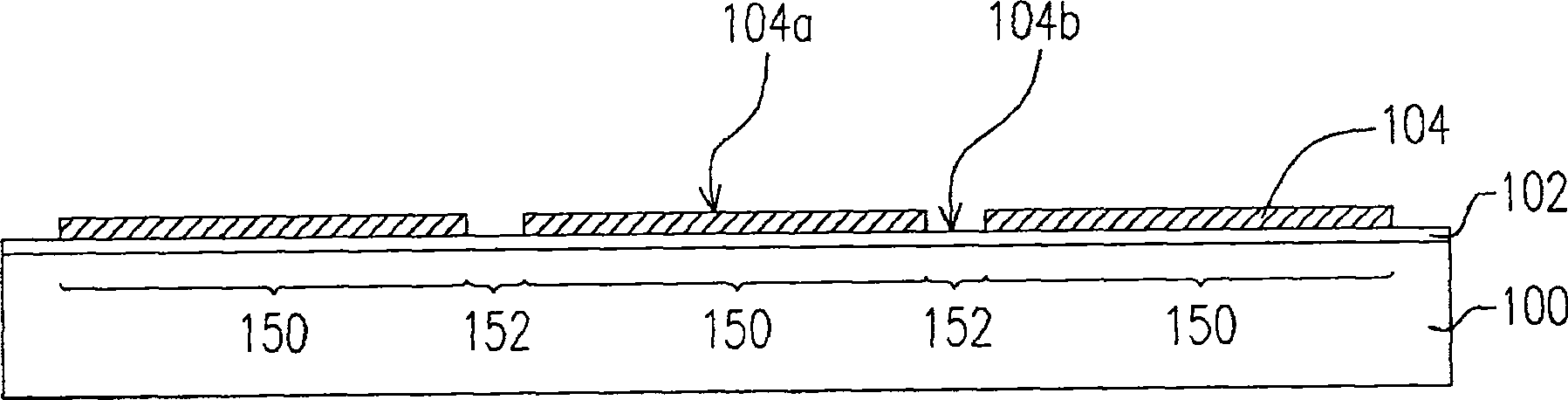

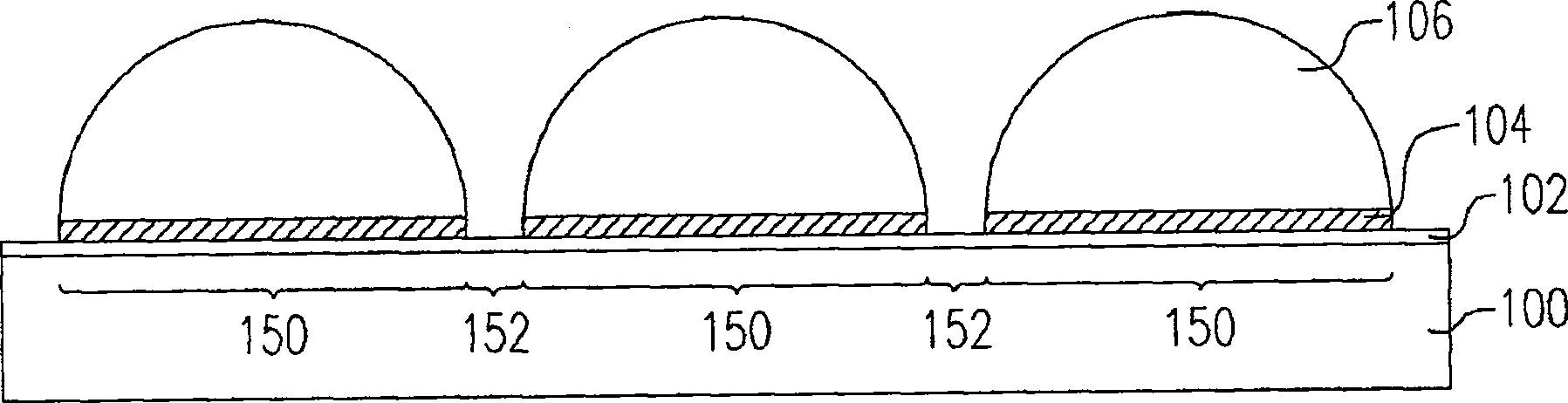

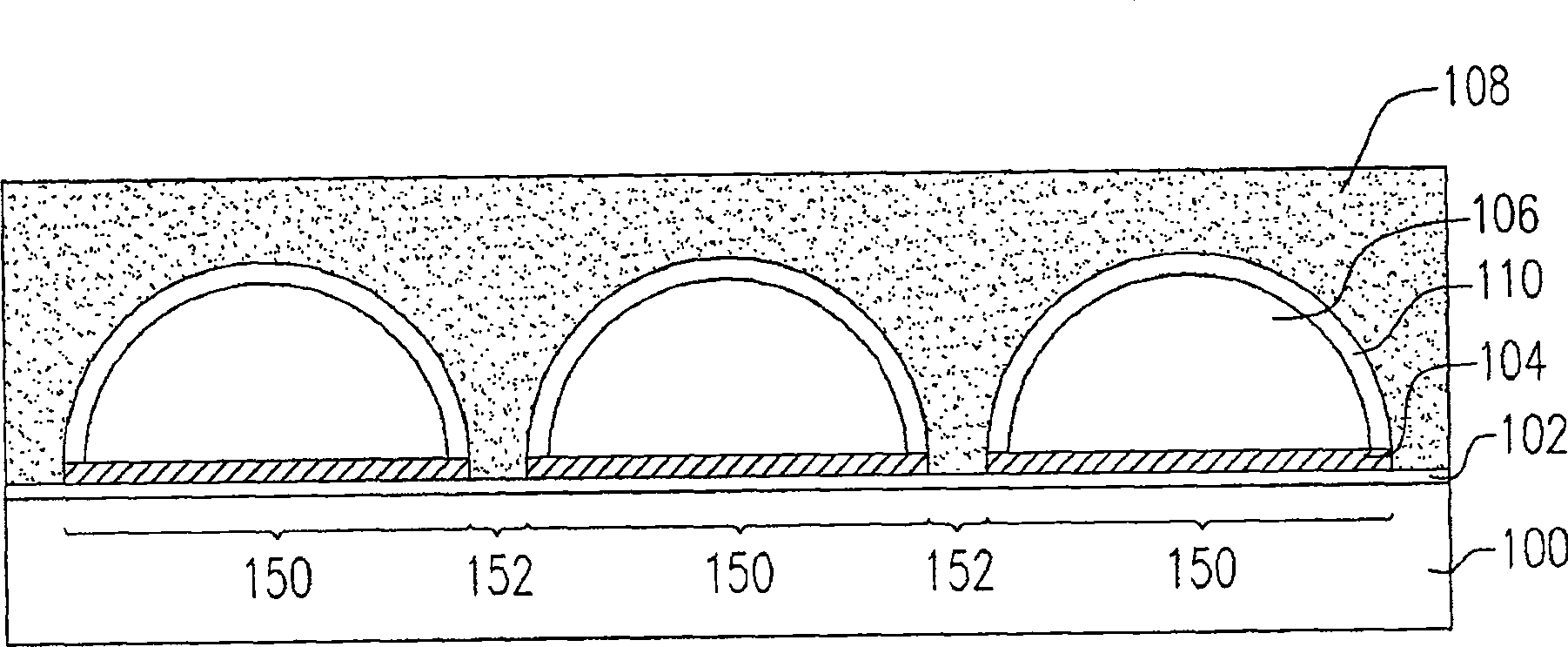

[0057] Figures 1A to 1G Illustrated is a schematic cross-sectional view of a method for manufacturing a flexible photoelectric thin film according to an embodiment of the present invention. Such as Figure 1A As shown, a substrate 100 is provided first. Afterwards, a conductive layer 102 is formed on the substrate 100 . The conductive layer 102 is, for example, a full conductive layer or a patterned conductive layer. The substrate 100 is, for example, a flexible or bendable or rigid substrate. The material of the substrate 100 includes plastic, metal, glass and other synthetic materials. The material of the conductive layer 102 includes a transparent conductive material, such as indium tin oxide (ITO), antimony tin oxide, or other synthetic materials. In addition, the material of the conductive layer 102 can also be a metal material, such as aluminum, copper, silver, molybdenum, chromium and the like. In addition, the material of the conductive layer 102 can also be a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com