Optical measuring method for in-plane vibration of micro-electromechanical structure

A micro-mechanical structure, optical measurement technology, applied in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problem of high equipment cost, achieve the effects of low cost, broad market and application prospects, and simple optical path structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention provides an optical measurement method for in-plane vibration of a micromechanical structure. Be described below in conjunction with accompanying drawing.

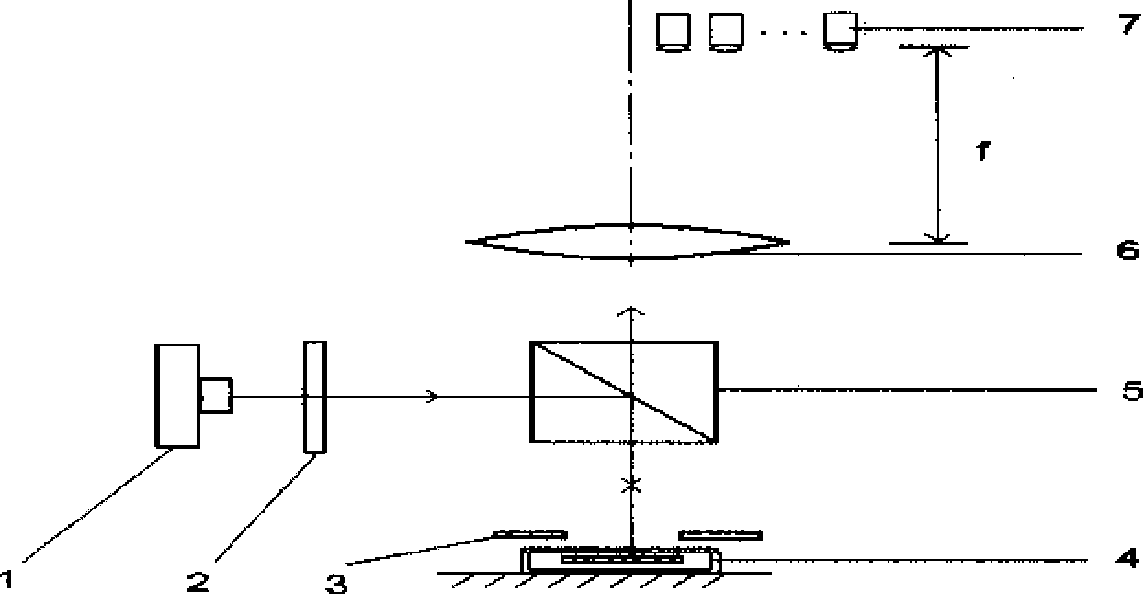

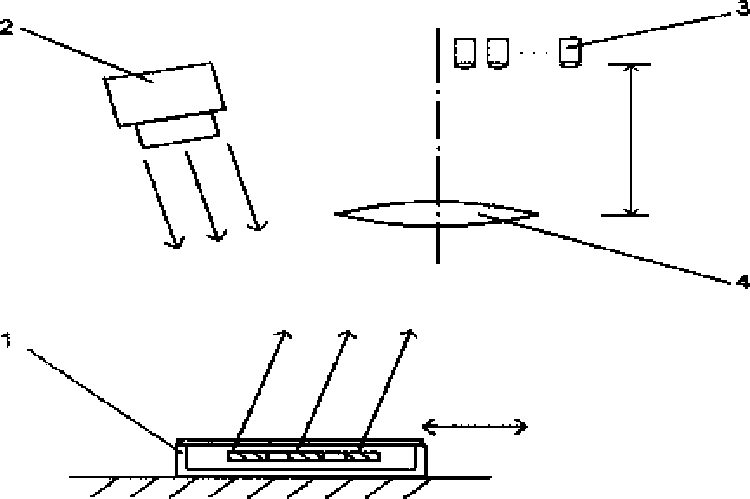

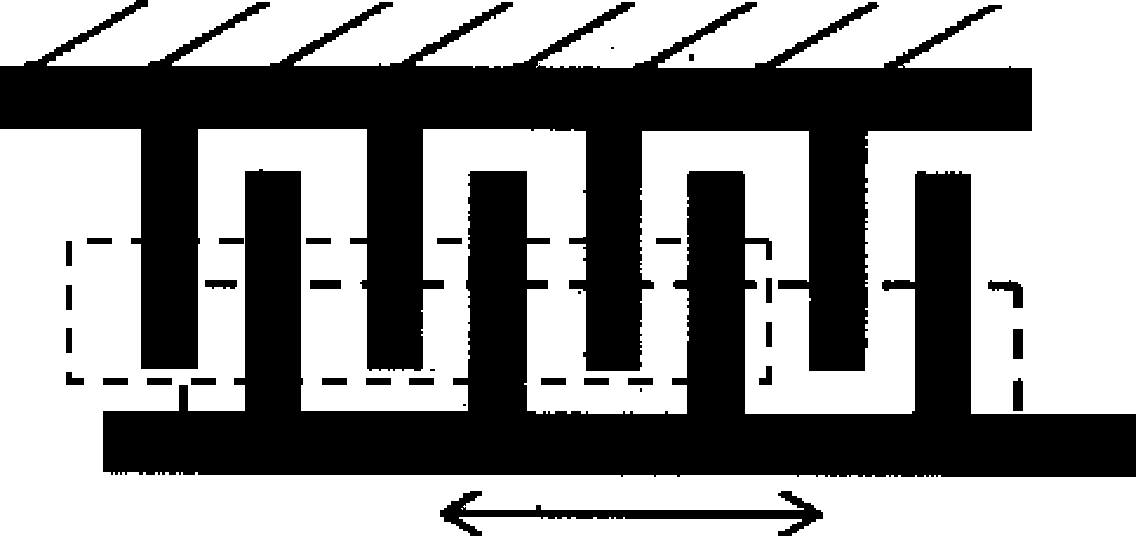

[0022] figure 1 Shown is a schematic diagram of an optical measurement device firstly established. The structure of the device is to place a polarizer 2 and a dichroic prism 5 in sequence in front of the light source 1. The dichroic prism 5 is placed directly above the plane of the micromechanical device to be measured. When the light source 1 And the polarizer 2 is placed on the upper left or right of the plane of the micromechanical device to be tested, and when the coherent parallel light produced is irradiated obliquely with the plane of the micromechanical device, the dichroic prism 5 (such as figure 2 shown). A Fourier lens 6 is fixed above the beam-splitting prism 5, and a photodetector 7 is fixed on the upper right of the Fourier lens 6; the measured micromechanical device 4 is placed below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com