Low-temperature low-density well cementing cement mortar

A cementing slurry, low density technology, applied in the field of cement slurry, can solve the problems of high construction requirements, out of control pressure, chemical foaming is difficult to control the speed and quantity of gas generation, etc., so that the thickening time is easier to control and work. Procedurally simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1170

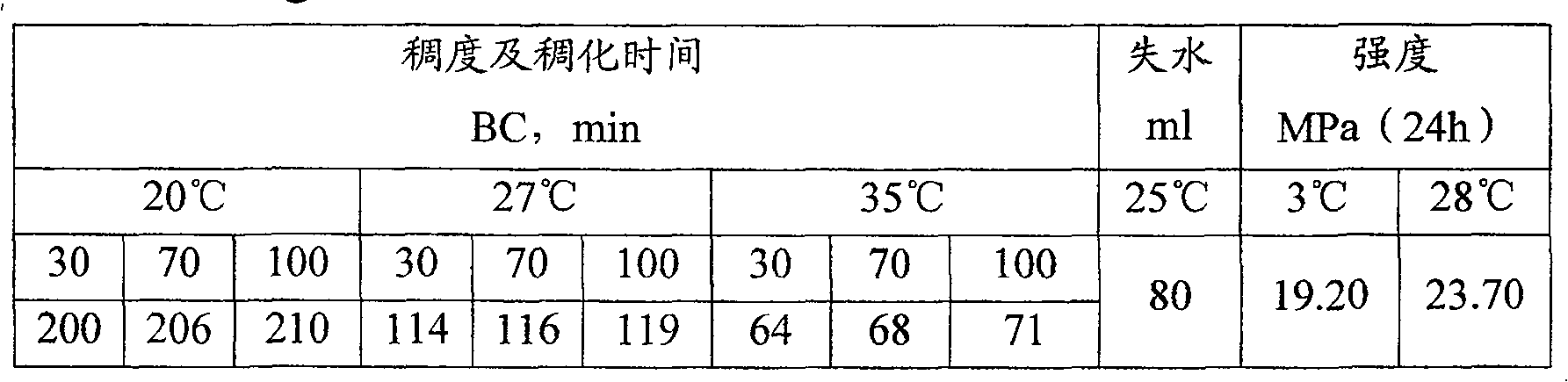

[0016] Example 11.70g / cm 3 Grout

[0017] First prepare the fluid loss reducer, according to deionized water 1200g, NNDMAM (N, N-dimethylacrylamide) 30.0g, AMPS (2 acrylamide-2 methylpropanesulfonic acid) 264g, (NH4) 2 S 2 o 8 1.5g, EDTA (ethylenediaminetetraacetic acid) 7.5g, NaOH 60.0g Weigh each component. The preparation steps are as follows: deionized water is poured into a 2000ml beaker, and then NNDMAM, AMPS, (NH 4 ) 2 S 2 o 8 , EDTA were dissolved in water in sequence; then pass N 2 20-40 minutes, heat to 60°C to start the reaction, stop heating when heated to 90°C, control the reaction temperature below 90°C, keep it at 70-85°C for 2 hours, discharge, then add solid NaOH to adjust the pH to medium The color of the product is light yellow. The prepared polymer has a solid content of about 20-30%.

[0018] Secondly, prepare the cement slurry: use a cement slurry mixing cup to measure 280g of water (for the convenience of configuration, you can also choose seaw...

Embodiment 2140

[0024] Example 21.40g / cm 3 Grout

[0025] First prepare fluid loss reducer, according to water 1036g, NNDMAM (N, N-dimethylacrylamide) 62.0g, AMPS (2 acrylamido-2 methylpropanesulfonic acid) 392g, (NH4) 2 S 2 o 8 4.7g, EDTA (ethylenediaminetetraacetic acid) 11.0g, NaOH 62.7g Weigh each component, and then prepare according to the preparation method of Example 1.

[0026] Secondly, weigh each component according to: 360g of fine high-strength cement, 240g of water, 1g of coagulation accelerator, 6.4g of retarder, 36g of fluid loss reducer, 1g of dispersant, 3.6g of stabilizer, 70g of auxiliary lightening agent, and carry out the rest. Mode is the same as embodiment 1.

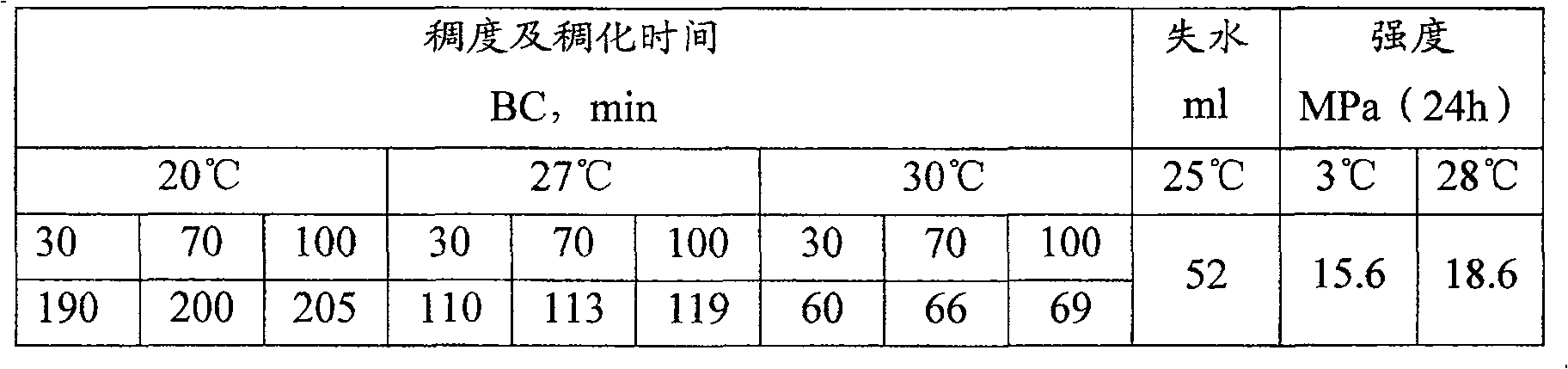

[0027] The test results of the low-temperature and low-density cementing slurry in this embodiment are shown in Table 2 below.

[0028] Table 2 Density 1.40g / cm 3 Grout

[0029]

Embodiment 3130

[0030] Example 31.30g / cm 3 Grout

[0031] First prepare the fluid loss reducer, according to water 1327g, NNDMAM (N, N-dimethylacrylamide) 15.7g, AMPS (2 acrylamide-2 methylpropanesulfonic acid) 188g, (NH4) 2 S 2 o 8 1.6g, EDTA (ethylenediaminetetraacetic acid) 4.7g, NaOH 31.4g Weigh each component, and then prepare according to the preparation method of Example 1.

[0032] Secondly, according to the thickness of high-strength cement 300g (50% fine, 50% thick, the ratio is percentage by weight), water 240g, coagulant 1.2g, retarder 5.8g, fluid loss reducer 36g, dispersant 0.9g, stable Agent 3g, auxiliary alleviating agent 100g weigh each component, all the other embodiments are the same as embodiment 1.

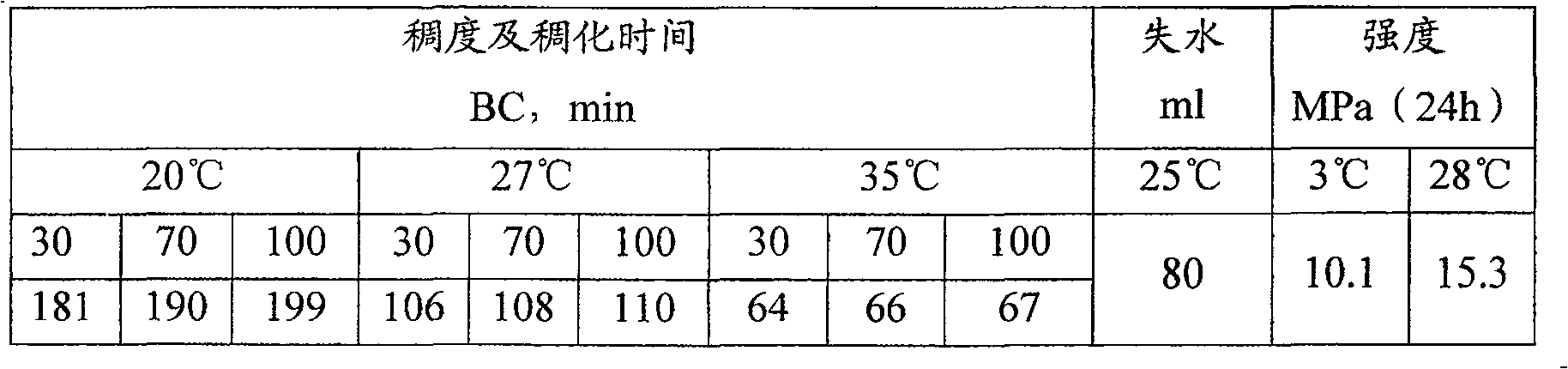

[0033] The test results of the low-temperature and low-density cementing slurry of this embodiment are shown in Table 3 below.

[0034] Table 3 Density 1.30g / cm 3 Grout

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com