High-strength low-freedom water low-density oil well cement paste

A technology of low-density cement and oil well cement, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of good controllability, achieve high strength, small free water, and easier thickening time The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

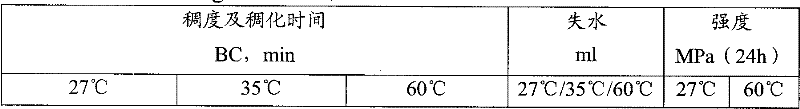

[0013] Example 1 1.52g / cm 3 Grout

[0014] First prepare the fluid loss reducer, according to 70g of polyvinyl alcohol, AMPS\AM\AA (2-acrylamido-2-methylpropanesulfonic acid / acrylamide / sodium acrylate) polymer 10.0g, crosslinking agent 15g, dispersion 5g of each component was weighed. The preparation steps are as follows: Pour polyvinyl alcohol into a 200ml beaker, then add AMPS\AM\AA (2-acrylamido-2-methylpropanesulfonic acid / acrylamide / sodium acrylate) polymer, crosslinking agent, dispersion The agents were poured into the beaker in turn; then stirred for 20 minutes to mix well. The prepared mixture is a fluid loss reducer.

[0015] Secondly, prepare the cement slurry: use a cement slurry mixing cup to measure 290g of seawater, 2g of retarder, 10g of dispersant, and 1.5g of defoamer to make mixed water, and put it on the Varin mixer at a constant speed of 4000 rpm while stirring. Add 615g of solid low-density cement materials (including 400g of G grade oil well cement, 1...

Embodiment 2

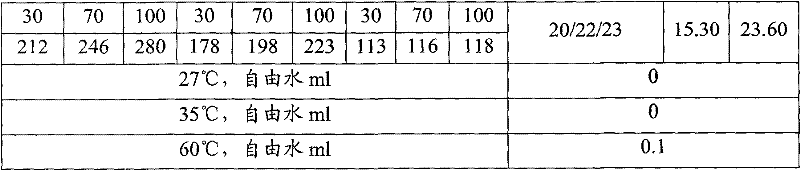

[0021] Example 2 1.50g / cm 3 Grout

[0022] First prepare the fluid loss reducer, according to 70g of polyvinyl alcohol, AMPS\AM\AA (2-acrylamido-2-methylpropanesulfonic acid / acrylamide / sodium acrylate) polymer 10.0g, crosslinking agent 15g, dispersion 5g of each component was weighed. The preparation steps are as follows: Pour polyvinyl alcohol into a 200ml beaker, then add AMPS\AM\AA (2-acrylamido-2-methylpropanesulfonic acid / acrylamide / sodium acrylate) polymer, crosslinking agent, dispersion The agents were poured into the beaker in turn; then stirred for 20 minutes to mix well. The prepared mixture is a fluid loss reducer.

[0023] Secondly, according to: G grade oil well cement 400g, seawater 320g, retarder 2g, defoamer 1.5g, fluid loss reducer 9g, dispersant 8g, lightening material 100g, ultrafine cement 60g, ultrafine slag 46g weigh each Components, all the other embodiments are the same as in Example 1.

[0024] The test results of the low-temperature, high-strengt...

Embodiment 3

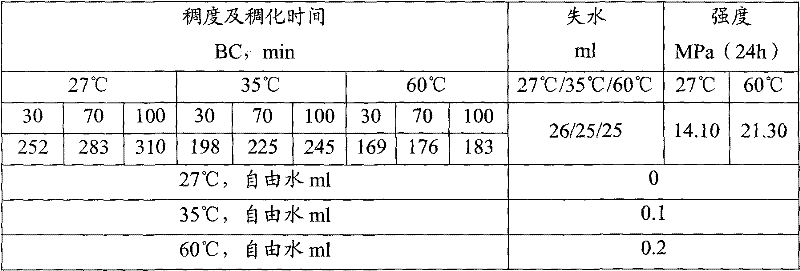

[0027] Example 3 1.48g / cm 3 Grout

[0028] First prepare the fluid loss reducer, according to 70g of polyvinyl alcohol, AMPS\AM\AA (2-acrylamido-2-methylpropanesulfonic acid / acrylamide / sodium acrylate) polymer 10.0g, crosslinking agent 15g, dispersion 5g of each component was weighed. The preparation steps are as follows: Pour polyvinyl alcohol into a 200ml beaker, then add AMPS\AM\AA (2-acrylamido-2-methylpropanesulfonic acid / acrylamide / sodium acrylate) polymer, crosslinking agent, dispersion The agents were poured into the beaker in turn; then stirred for 20 minutes to mix well. The prepared mixture is a fluid loss reducer.

[0029] Secondly, according to: G grade oil well cement 400g, seawater 340g, retarder 2g, defoamer 1.5g, fluid loss reducer 9g, dispersant 8g, lightening material 100g, ultrafine cement 60g, ultrafine slag 46g weigh each Components, all the other embodiments are the same as in Example 1.

[0030] The test results of the cementing low-temperature hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com