Explosive compacting method capable of eliminating additional temperature affection

A technology of compaction and density, which is applied in the field of explosive compaction, can solve the problems of reducing the powder phase transformation conversion rate, increasing the powder additional temperature, and less phase change, so as to improve the product conversion rate and eliminate the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

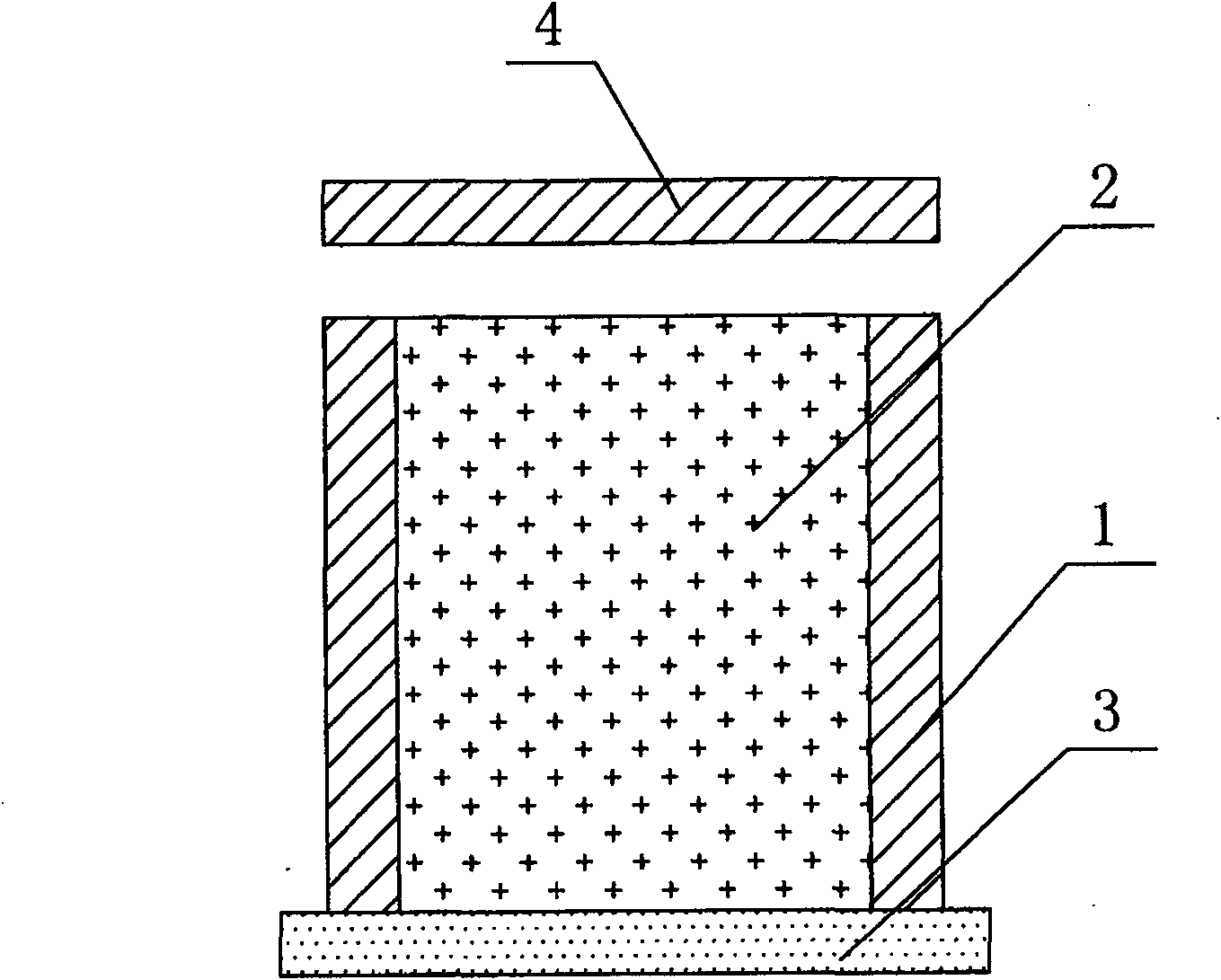

[0022] a. Same as the prior art, powders such as graphite powder, graphite and metal mixed powder, graphite and metal, resin mixed powder are placed in mold 1 to make powder compacted body 2;

[0023] b. If figure 1 Shown: the mold 1 that powder compaction body 2 is housed is placed under the flyer 4 of the explosive device and is placed on the metal layer 3 pressed with copper powder or iron powder or cobalt powder etc. in advance, and the density of the metal layer 3 is this 40-65% of the metal crystal density, the height of the metal layer 3 can be set according to needs, preferably 1 / 10-1 / 4 of the powder layer thickness;

[0024] c. detonate the explosive column in the explosive device;

[0025] d. Recover the powder ash, and carry out post-processing on the powder ash, such as screening, washing, and eliminating residual non-phase-change powder, to obtain the desired product.

Embodiment 2

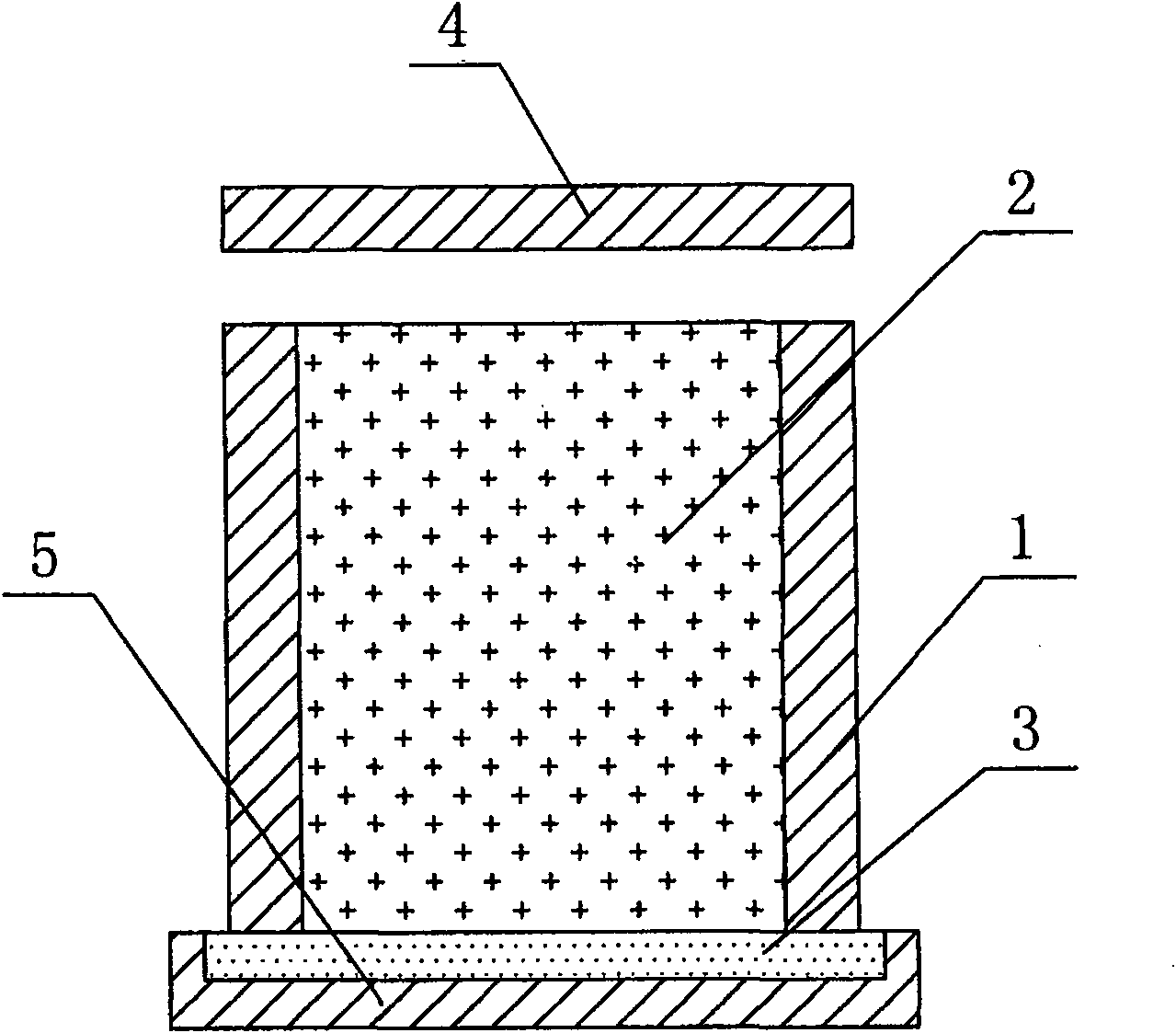

[0027] a. Same as the prior art, powders such as graphite powder, graphite and metal mixed powder, graphite and metal, resin mixed powder are placed in mold 1 to make powder compacted body 2;

[0028] b. If figure 2 As shown: the mold 1 with the powder compacted body 2 inside is placed under the flyer 4 in the explosive device and placed on the metal layer 3 such as copper powder, iron powder or cobalt powder, the density of the metal layer 3 is less than that of the metal crystal 40% of the density, that is, in a loose state, so a support plate 5 needs to be placed under the metal layer 3, and the support plate 5 can be any material, such as metal, plastic, wood or cardboard, etc. Plastic, wood or cardboard have light weight , cheap advantages;

[0029] c. detonate the explosive column in the explosive device;

[0030] d. Recover the powder ash, and carry out post-processing on the powder ash, such as screening, washing, and eliminating residual non-phase-change powder, to...

Embodiment 3

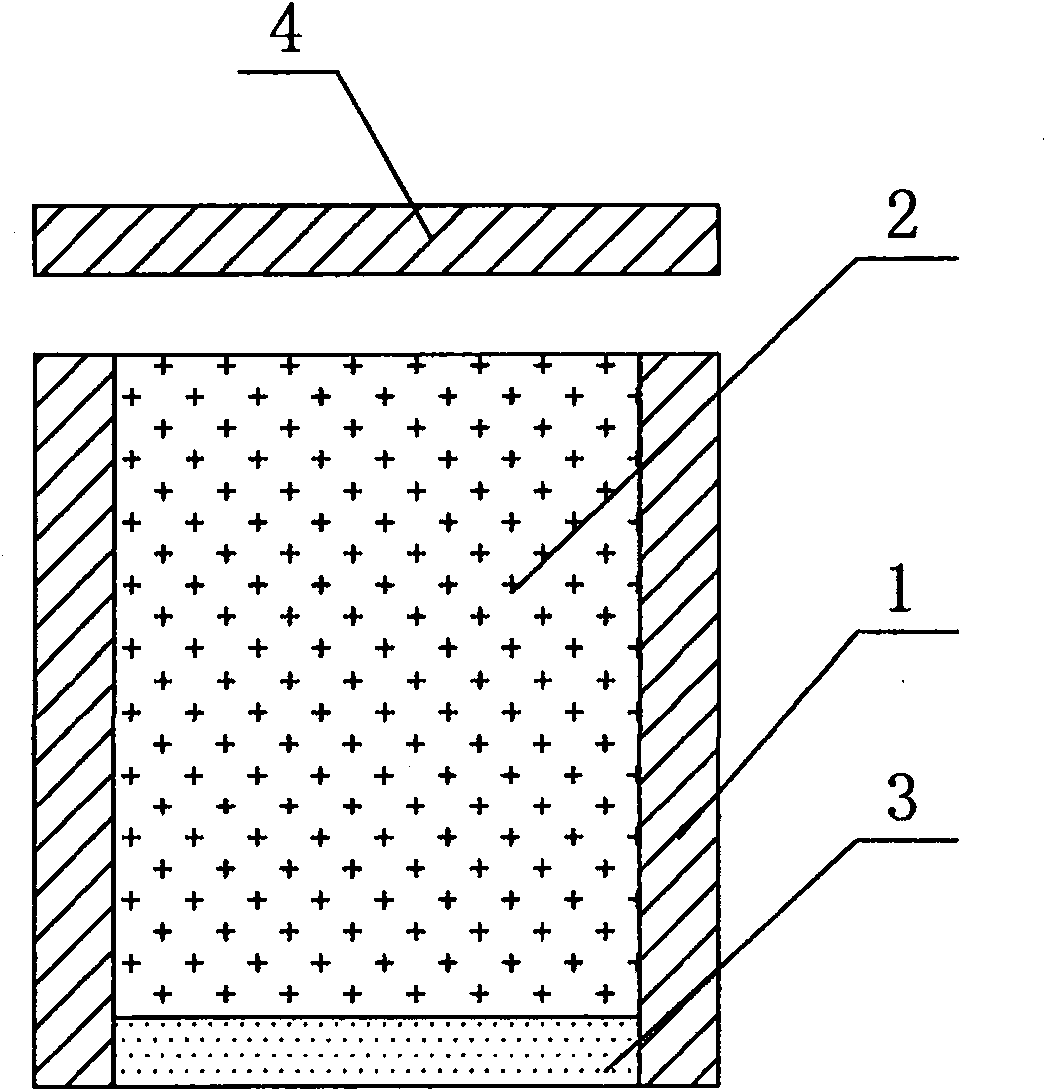

[0032] a. Same as the prior art, powders such as graphite powder, graphite and metal mixed powder, graphite and metal, resin mixed powder are placed in the mold 1 to make a powder compacted body 2, and then as image 3 As shown: a space of 1 / 10 to 1 / 4 of the height of powder compacted body 2 is reserved on the top of powder compacted body 2 in mold 1, and metal powder (copper powder, iron powder or cobalt powder) is placed on powder compacted body 2 In the space above, use less than 1.5KN / cm 3 The pressure is pressed to form a metal layer 3 placed in the mold 1, and the density of the metal layer 3 is 40% to 65% of the metal crystal density;

[0033] b. Overturn the mold 1 with the powder compacted body 2 and the metal layer 3 inside by 180 degrees, and place it under the flying piece 4 in the explosive device;

[0034] c. detonate the explosive column in the explosive device;

[0035] d. Recover the powder ash, and carry out post-processing on the powder ash, such as screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com