Production technique of steel skeleton plastic composite pipe having plastic end and products thereof

A production process and steel skeleton technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve problems such as the influence of connection stability, different shapes at both ends, and complicated production processes, so that the welding pressure can be controlled , The effect of human factors is small, and the quality is easier to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

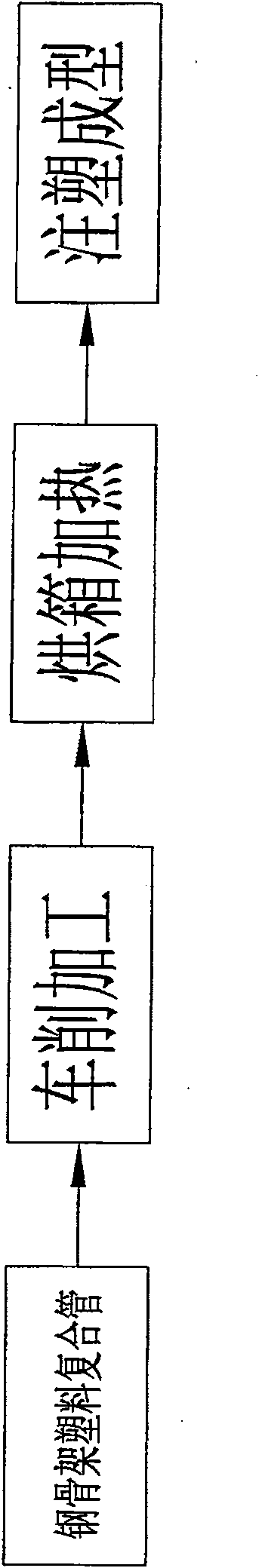

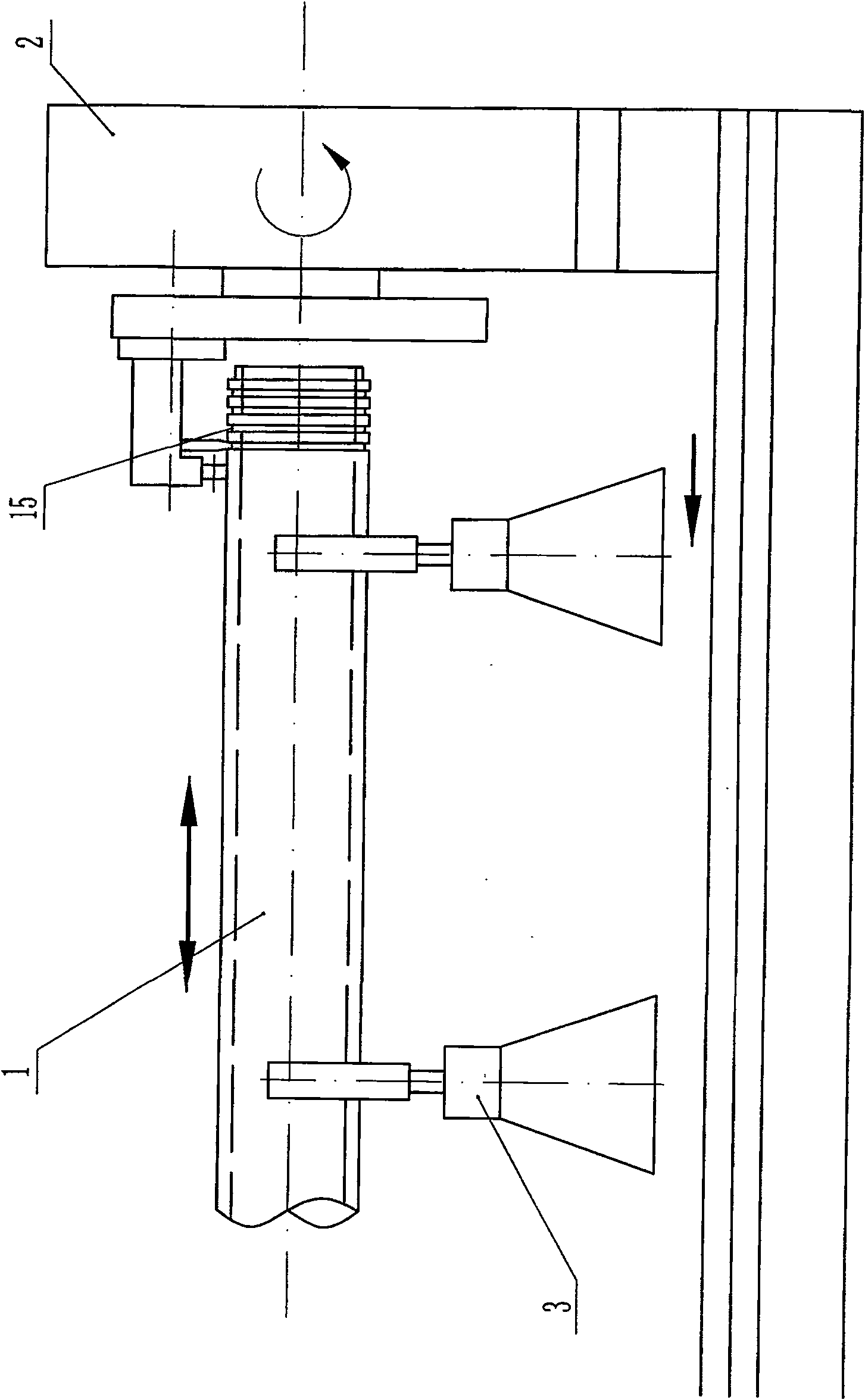

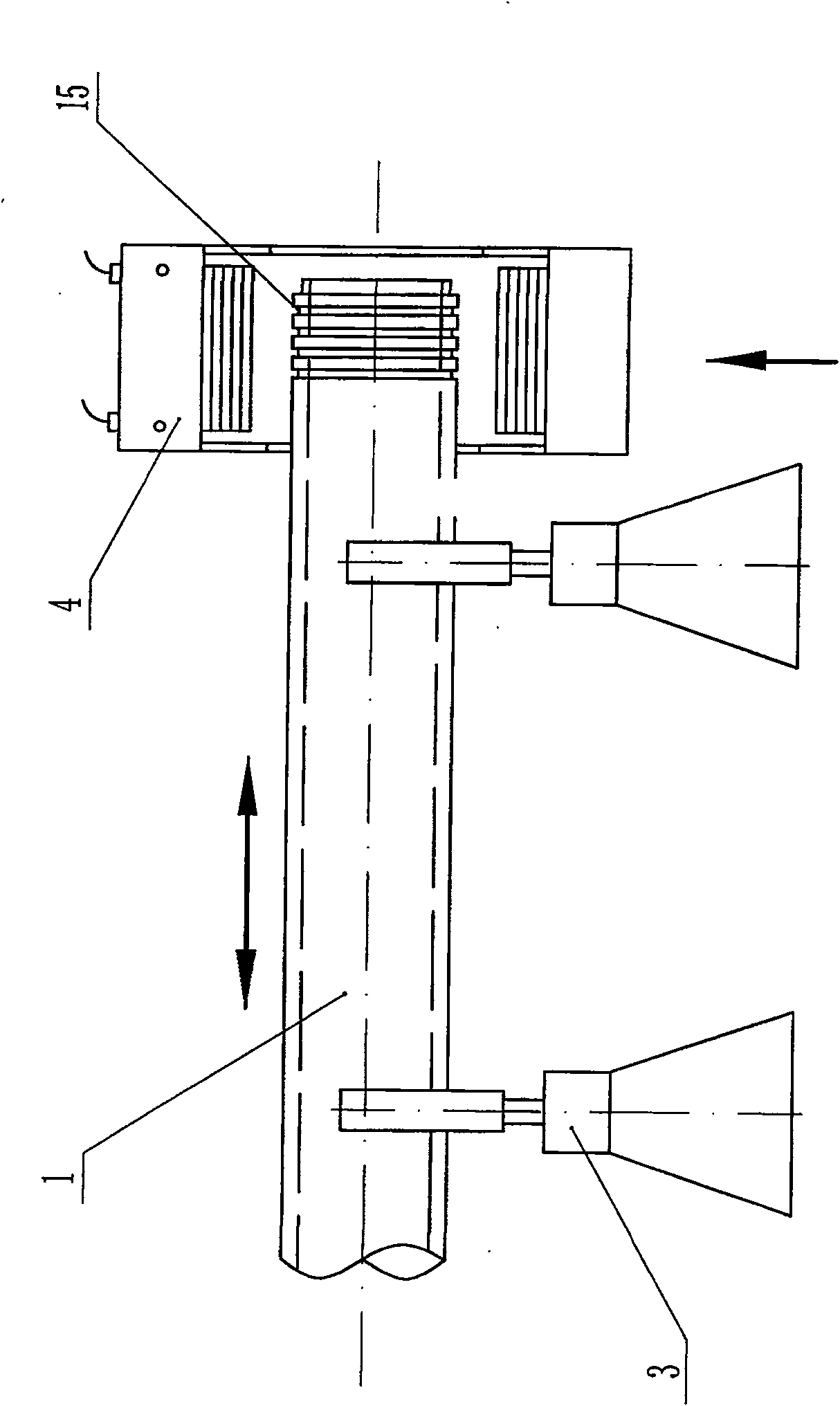

[0032] Such as Figure 1-6 As shown in the specific embodiment of the present invention, a steel skeleton plastic composite pipe 1 is prepared, and this steel skeleton plastic composite pipe 1 includes a steel skeleton 11 and a plastic layer 12 coated inside and outside the steel skeleton, the two constitute a composite structure, the described The steel frame 11 can be in the form of perforated steel strips, steel wire mesh, etc. The inner and outer plastic layers can be made of plastic materials such as PE and PVC, and then the steel frame plastic composite pipe 1 is placed on the pipeline delivery frame 3, and the steel frame On the outer plastic layer 12 of the end of the plastic composite pipe, several annular grooves 15 are processed by the turning machine 2, preferably the depth of the annular grooves is 0.5-1mm, and then the steel skeleton plastic is compounded by the pipeline conveying frame 3 The end of the pipe 1 is sent into the oven 4, the plastic layer 12 at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com