Capillary pipe optical fibre and standard optical fibre connecting method

A standard optical fiber and connection method technology, applied in the direction of cladding optical fiber, optical waveguide light guide, optical waveguide coupling, etc., can solve the problems of different optical waveguide geometric shapes and different fiber cross-sectional area ratios, etc. Create easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

[0038] The present invention is realized in this way during the production and implementation process, including the following steps:

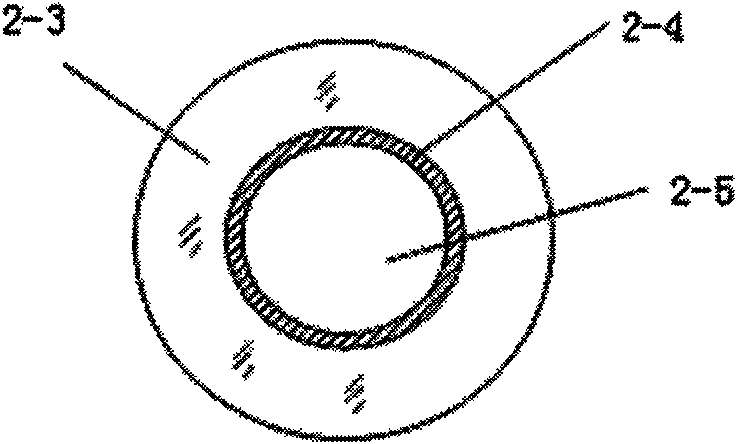

[0039] 1. Such as Figure 2-a For the hollow capillary fiber shown, peel off the coating layer at one end of it, and then clean it. During the cleaning process, avoid liquid entering the hollow cavity of the capillary fiber;

[0040] 2. Carefully cut out the flat capillary fiber end face;

[0041] 3. Prepare the fiber end of the standard physical single-core fiber to be connected according to the same steps as above;

[0042] 4. Cover the prepared section of quartz protective tube on one end of the standard single-core fiber or capillary fiber;

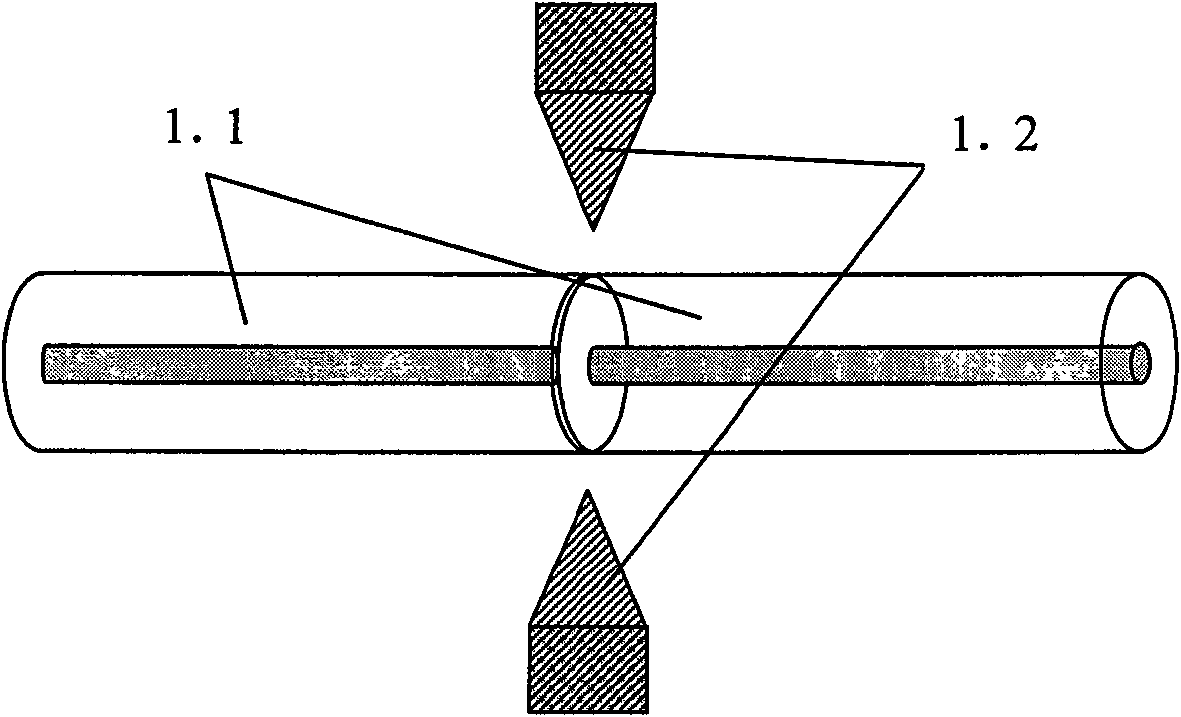

[0043] 5. Butt and weld the prepared two fiber ends in the fiber fusion splicer, such as figure 1 Shown

[0044] 6. In the implementation of fusion tapering, since the two optical fibers used have the same diameter, both are 125 microns. The softening point of the hollow capillary fiber material is the s...

Embodiment ( 2

[0048] The second embodiment of the present invention is implemented in this way during the production and implementation process, and includes the following steps:

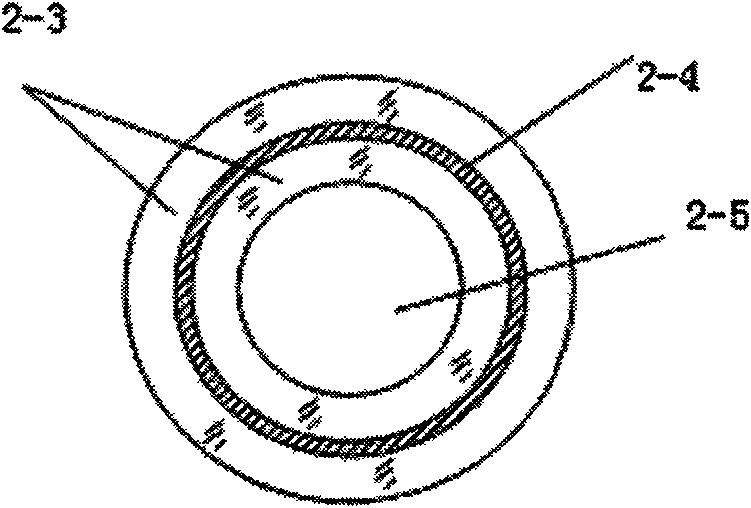

[0049] 1. Take as Figure 2-b For the hollow capillary fiber shown, peel off the coating layer at one end of it, and then clean it. During the cleaning process, avoid liquid entering the hollow cavity of the capillary fiber;

[0050] 2. Carefully cut out the flat capillary fiber end face;

[0051] 3. Prepare the fiber end of the standard physical single-core fiber to be connected according to the same steps as above;

[0052] 4. Cover the prepared section of quartz protective tube on one end of the standard single-core fiber or capillary fiber;

[0053] 5. Butt and weld the prepared two fiber ends in the fiber fusion splicer, such as figure 1 Shown

[0054] 6. In fact, when the tapering is melted, the two optical fibers used have the same diameter, both of which are 125 microns. The softening point of the hollow cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com