Printed wiring board

A technology of printed circuit boards and conductor circuits, which is applied in the manufacture of printed circuit components and multilayer circuits, and can solve problems such as IC malfunctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

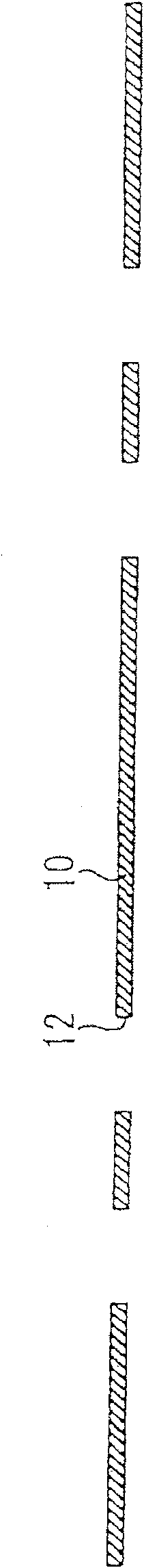

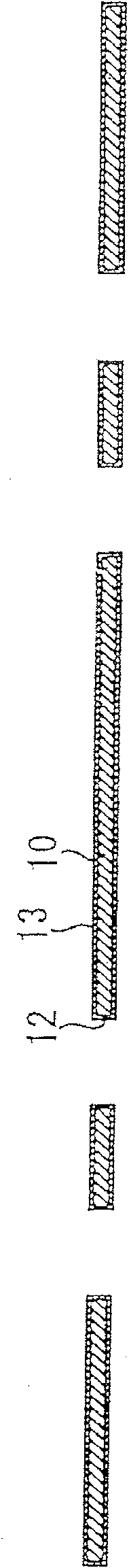

Image

Examples

Embodiment 1

[0042] (A) Preparation of kneaded product containing scaly particles

[0043] To a mixed solvent of 20 g of methyl ethyl ketone (hereinafter referred to as "MEK") and 80 g of xylene was added 15 g of scaly particles (manufactured by Hojun Co., Ltd., trade name "Esben C"), and the aspect ratio at the time of dispersion : ~500, crystal size: ~0.5μm), and kneaded with three rollers to make a kneaded product containing scaly particles.

[0044] (B) Preparation of solution containing epoxy resin

[0045] To a mixed solvent of 6.8 g M EK and 27.2 g of xylene, 85 g of solid epoxy resin (manufactured by Japan EPOXY RESIN, trade name "Epicoat 1007") was added and mixed to form a ring-containing solution of oxygen resin.

[0046] (C) Preparation of resin film for interlayer insulating layer

[0047] The kneaded product containing the scaly particles produced in the above (A), the solution containing the epoxy resin produced in the above (B), and dicyandiamide (bii·tei· Ai Japan (BTA...

Embodiment 2

[0162] Change the mask for pattern formation of the plating resist layer, and change the electrolytic copper plating conditions and the thickness of the conductive circuit after film thickness adjustment so that the L / S of the signal line is 7.5 μm / 7.5 μm, and the thickness T of the conductive circuit is 7.5 μm, except Other than that, a multilayer printed wiring board was produced in the same manner as in Example 1.

[0163] In this embodiment, the value of |W1-W2| is 0.675 μm to 2.775 μm, which basically satisfies the relationship of (0.10×thickness T of the conductive circuit) to (0.35×thickness T of the conductive circuit). Also, the standard deviation σ of |W1-W2| was 1.33 μm.

Embodiment 3

[0165] Change the mask for pattern formation of the plating resist layer, and change the electrolytic copper plating conditions and the thickness of the conductive circuit after film thickness adjustment so that the L / S of the signal line is 10.0 μm / 10.0 μm, and the thickness T of the conductive circuit is 10.0 μm, except Other than that, a multilayer printed wiring board was produced in the same manner as in Example 1.

[0166] In this embodiment, the value of |W1-W2| is 0.9 μm to 3.6 μm, which basically satisfies the relationship of (0.10×thickness T of the conductive circuit) to (0.35×thickness T of the conductive circuit). Also, the standard deviation σ of |W1-W2| was 1.27 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com