Liquid-discharging system and fractionating rectifying tower using same

A rectifying tower and liquid technology, applied in the control/regulation system, liquid level control, distillation regulation/control, etc., can solve the problems of high cost of the kettle liquid discharge system, difficult application and promotion, and high production cost, and achieve liquid temperature and liquid temperature. The effect of convenient adjustment of bit parameters, good safety, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof, but embodiment description does not limit the claims of the present invention:

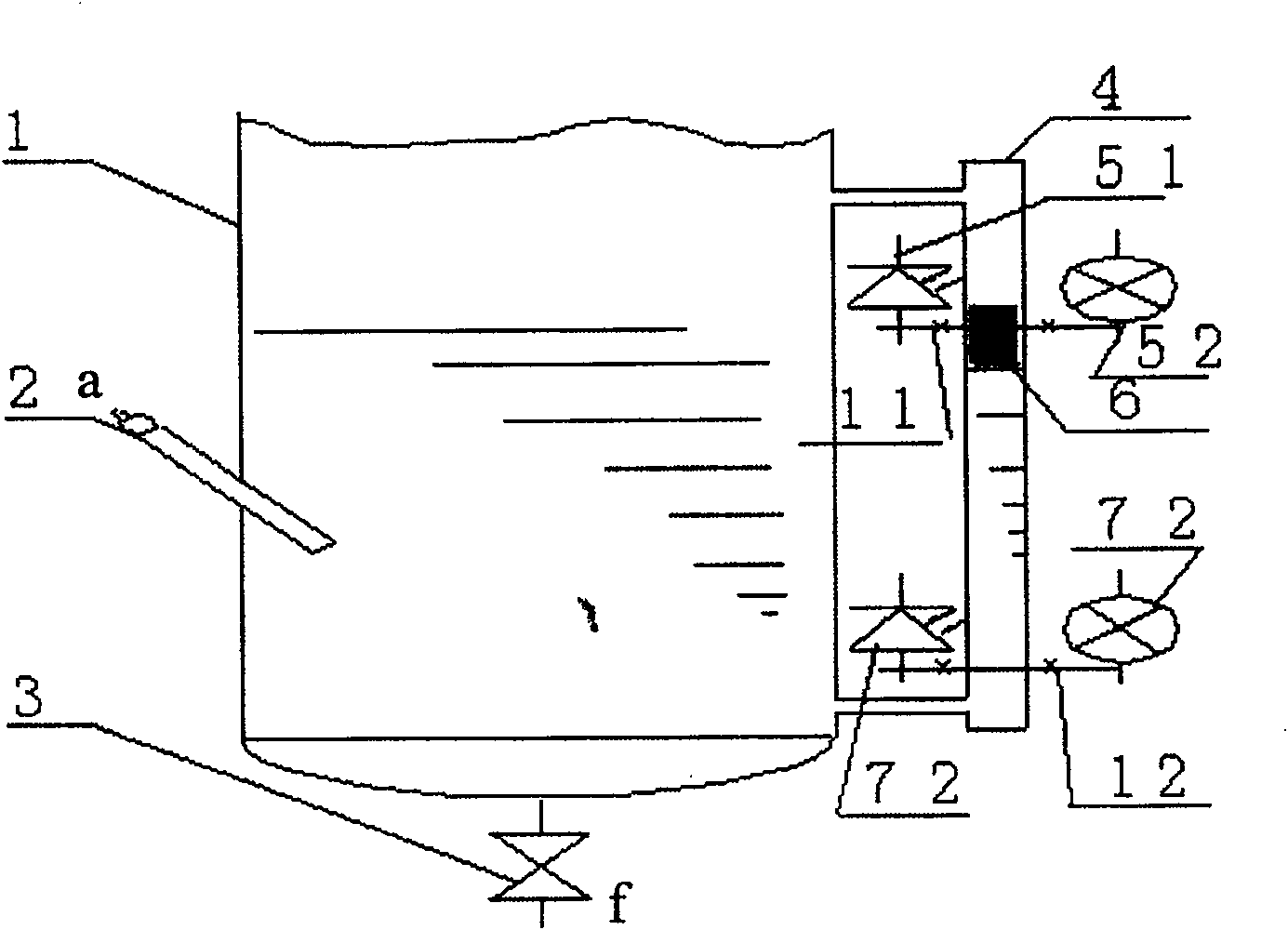

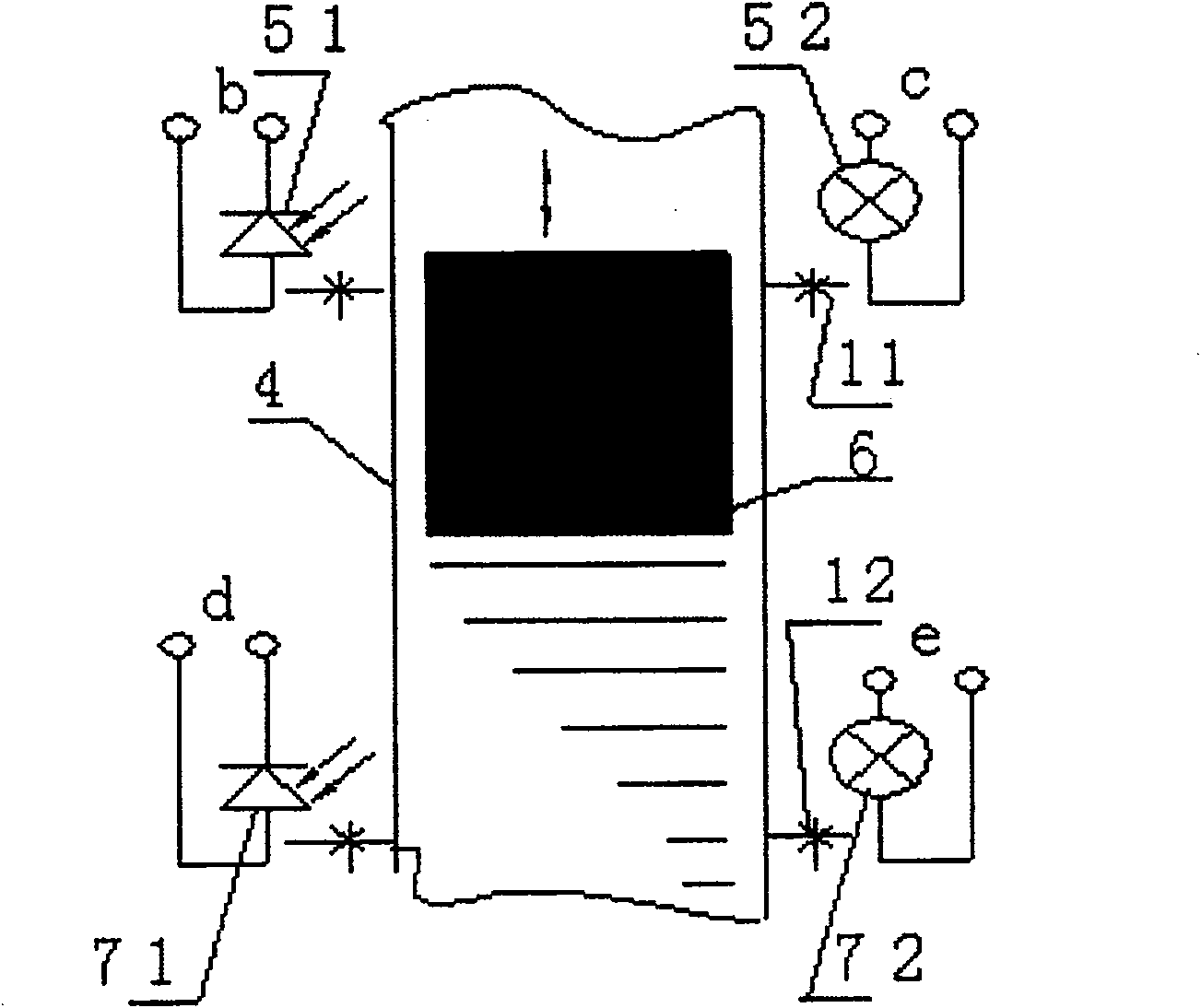

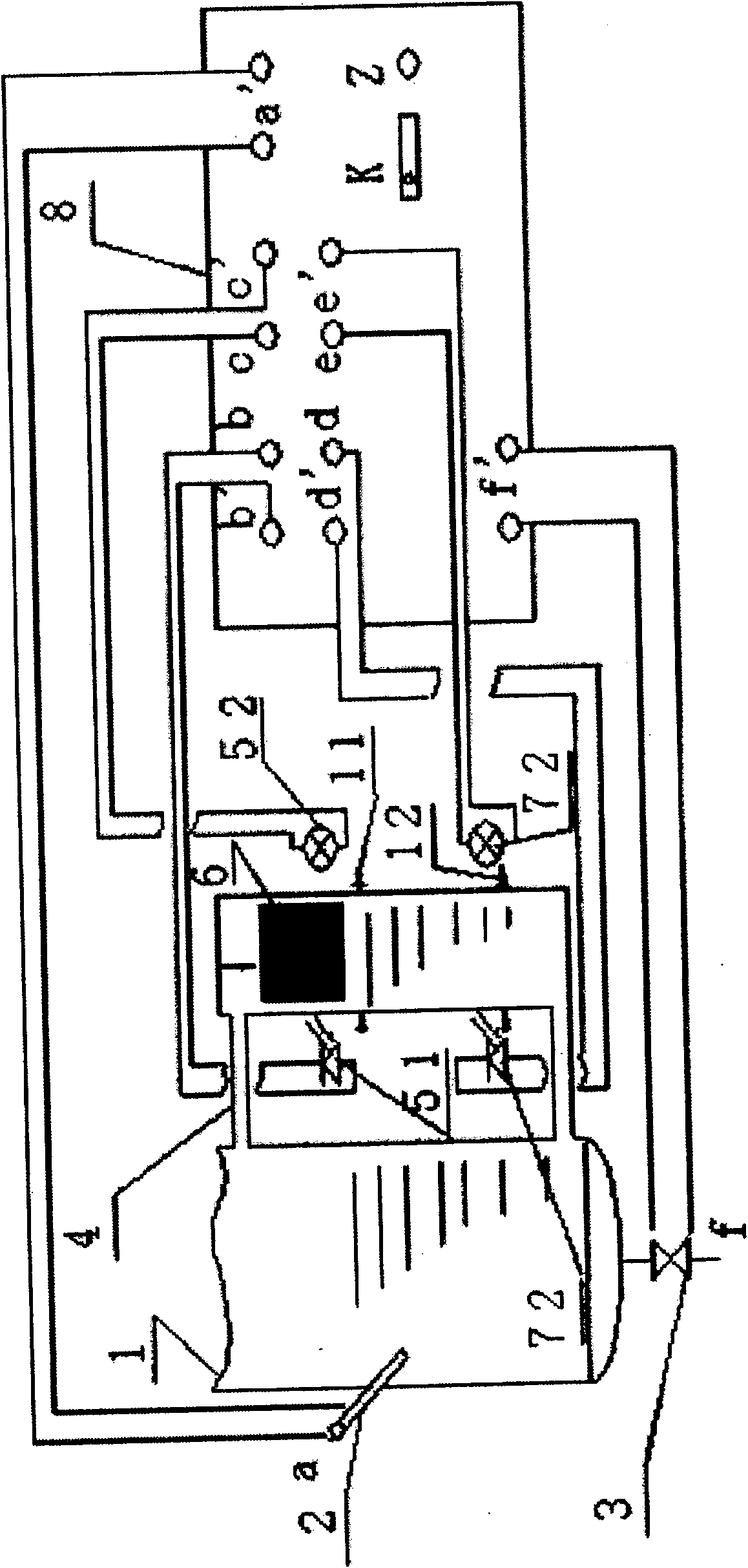

[0017] A kind of liquid discharge system designed by the present invention (hereinafter referred to as discharge system, see Figure 1-7 ), mainly including electric contact thermometer 2, liquid discharge solenoid valve 3, glass tube liquid level gauge 4, upper and lower liquid level limit photoelectric components 5,7. The electric contact thermometer 2 and the upper and lower liquid level limit photoelectric components 5, 7 are used as sensing components and connected with relevant terminals in the control box according to the "AND gate" logic circuit to form an "AND gate" logic control system. The "AND gate" logic control system of the present invention is an automatic control system that generates a liquid discharge working signal output when the preset temperature signal output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com