Endless paper gravure press large-area frosting and printing technology

A gravure printing machine, a large-area technology, applied in the printing process, printing, printing post-processing, etc., can solve the problems of poor precision, slow silk screen production speed, unstable quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

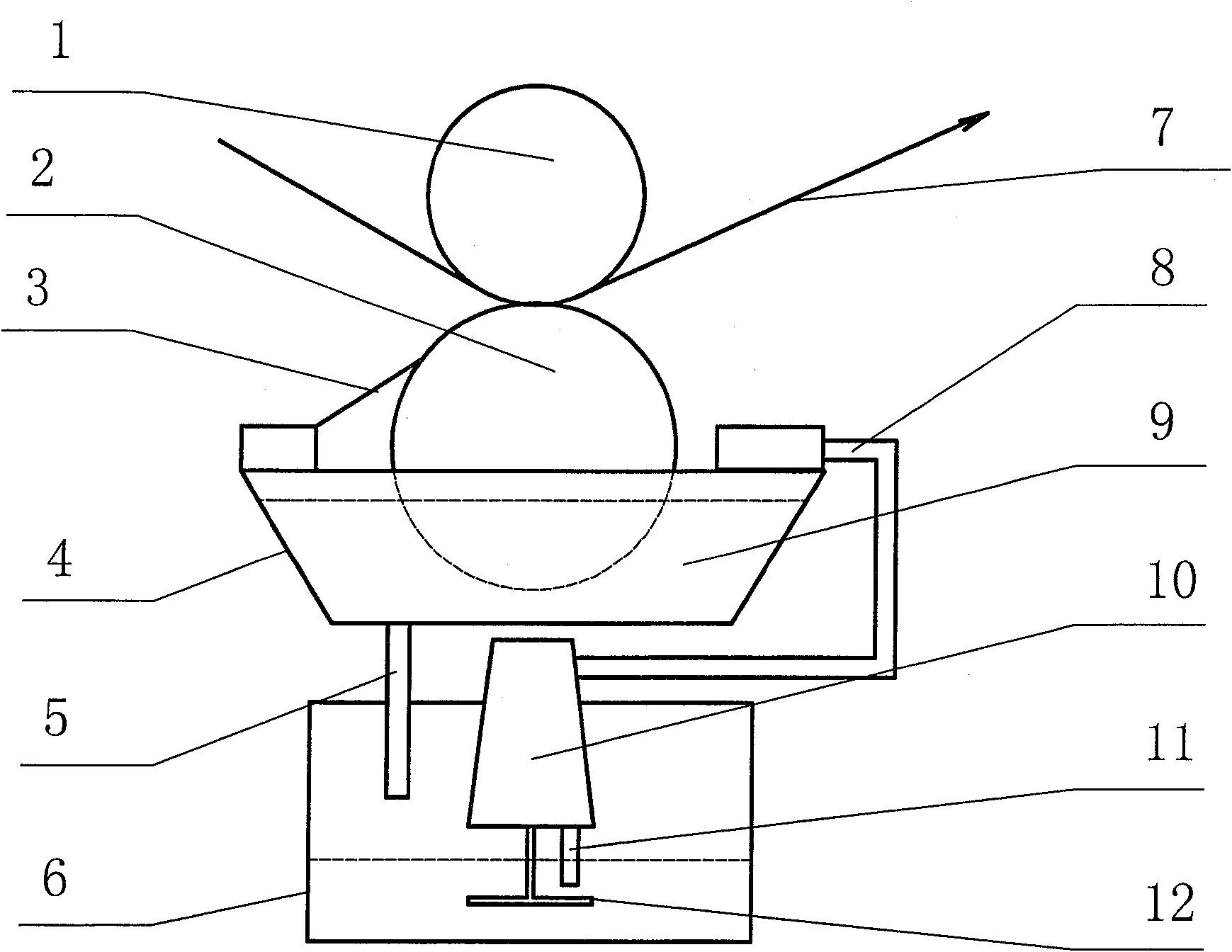

[0014] The relevant technical issues will be further described in detail below, and the specific implementation manners of the present invention will be described in detail in conjunction with the accompanying drawings. First of all, it should be explained that the matte printing mentioned in the present invention is a mature technology in the prior art and has been applied in many fields. Its principle and process are: print a UV light-curable ink on the paper, and then cure the ink (that is, dry) under ultraviolet (UV) irradiation, and the ink particles left on the paper present a metal-like The effect of etching, so this type of printing is called matte printing. The UV light-curable ink used therein is a mature product in the prior art, and various UV light-curable ink products have come out. The problem in the prior art is that although there are various UV photocurable ink products, there are also mature methods for forming UV photocurable inks with a frosted glass-like...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com