Surface luminescence device

A surface emitting, blue light technology, applied in luminescent materials, lighting devices, fluorescence and other directions, can solve the problems of low luminous efficiency white light LED, low luminous efficiency phosphor luminous conversion efficiency and other problems, achieve high luminous efficiency, excellent color rendering, high brightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

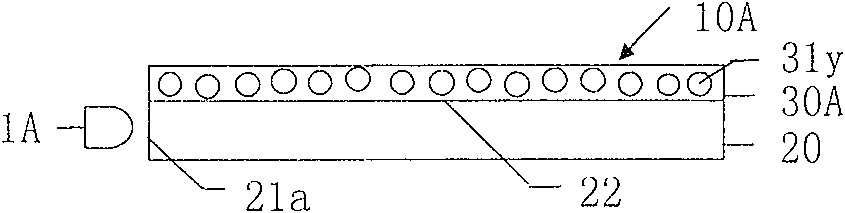

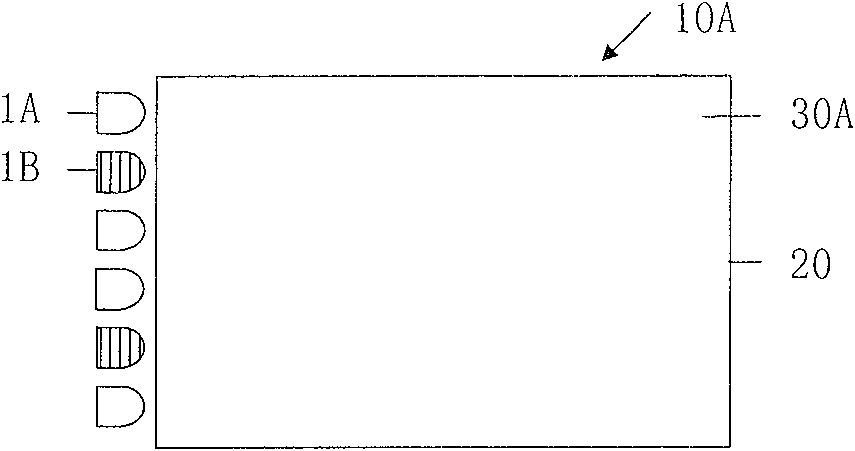

[0042] FIG. 1 shows a surface light-emitting device 10A of Example 1. As shown in FIG. FIG. 1( a ) and FIG. 1( b ) are views of the surface light-emitting device 10A viewed from one side and from the upper side, respectively. The surface emitting device 10A is composed of a plurality of blue LEDs 1A, a plurality of light-storing blue LEDs 1B, a light guide plate 20, a yellow phosphor layer 30A, a power supply and a circuit (not shown) for driving the LEDs 1A and 1B. figure 2 A cross-sectional view of LED1B is shown.

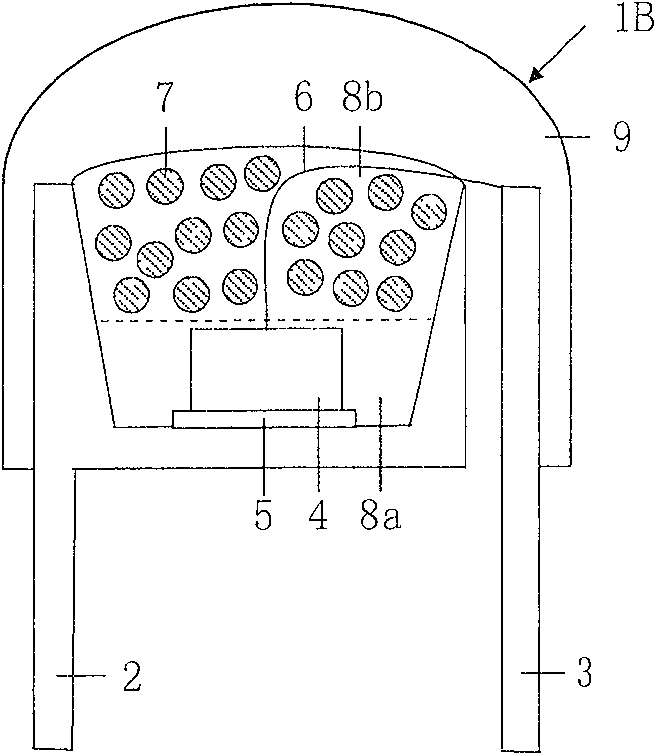

[0043] LED1B is composed of lead wires 2 and 3, ultraviolet LED chip 4 with a peak wavelength of 380nm, conductive glue 5, bonding wire 6, light-storing blue phosphor powder 7, resins 8a, 8b and sealing resin 9. A recess is provided on the lead wire 2, on which the ultraviolet LED chip 4 is placed. The ultraviolet LED chip 4 is electrically connected to the lead wire 2 through the conductive glue 5 , and is electrically connected to the lead wire 3 through the ...

Embodiment 2

[0050] FIG. 3 shows a surface emitting device 10B of Example 2. As shown in FIG. 3(a) and 3(b) are views of the surface light-emitting device 10B viewed from one side and the top, respectively. The difference from the surface-emitting device 10A of Embodiment 1 is that in the surface-emitting device 10B of Embodiment 2, the yellow phosphor layer 30A is arranged between LED1A, LED1B and the light-introducing surface 21 a of the light guide plate 20 . The rest are the same as those of the surface light-emitting device 10A.

[0051] When the surface light-emitting device 10B is working, first, blue light is emitted from LED1A and LED1B, part of the blue light is absorbed by the yellow phosphor 31y in the yellow phosphor layer 30A, and converted into yellow light by wavelength. The yellow light is mixed with the blue light without the wavelength conversion of the yellow fluorescent powder 31y to become white light, and then it is introduced into the light guide plate 20 from the ...

Embodiment 3

[0053] FIG. 4 shows a surface light-emitting device 10C of the third embodiment. 4(a) and 4(b) are views of the surface light-emitting device 10C viewed from one side and the top, respectively. The difference from the surface-emitting device 10B of Embodiment 2 is that in the surface-emitting device 10C of Embodiment 3, the LED 1A is disposed on the light-introducing surface 21a side (left side) of the light guide plate 20, and the violet LED 1C with a peak wavelength of 415nm is disposed On the side (right side) of the light introduction surface 21b of the light guide plate 20 . The phosphor layer consists of a yellow phosphor layer 30A and a white phosphor layer 30B, which are arranged between the LED 1A and the light-introducing surface 21 a of the light guide plate 20 and between the LED 1C and the light-introducing surface 21 b of the light guide plate 20 . The yellow phosphor layer 30A is the same as the yellow phosphor layer 30A in the surface emitting device 10A of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com