Self-balancing rotary laser

A laser instrument and self-balancing technology, which is applied in the field of laser instruments, can solve the problems that the rotating laser instrument cannot be replaced, and the 360° reference line cannot be displayed, so as to achieve the effects of simplifying the structure, ensuring coaxiality, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

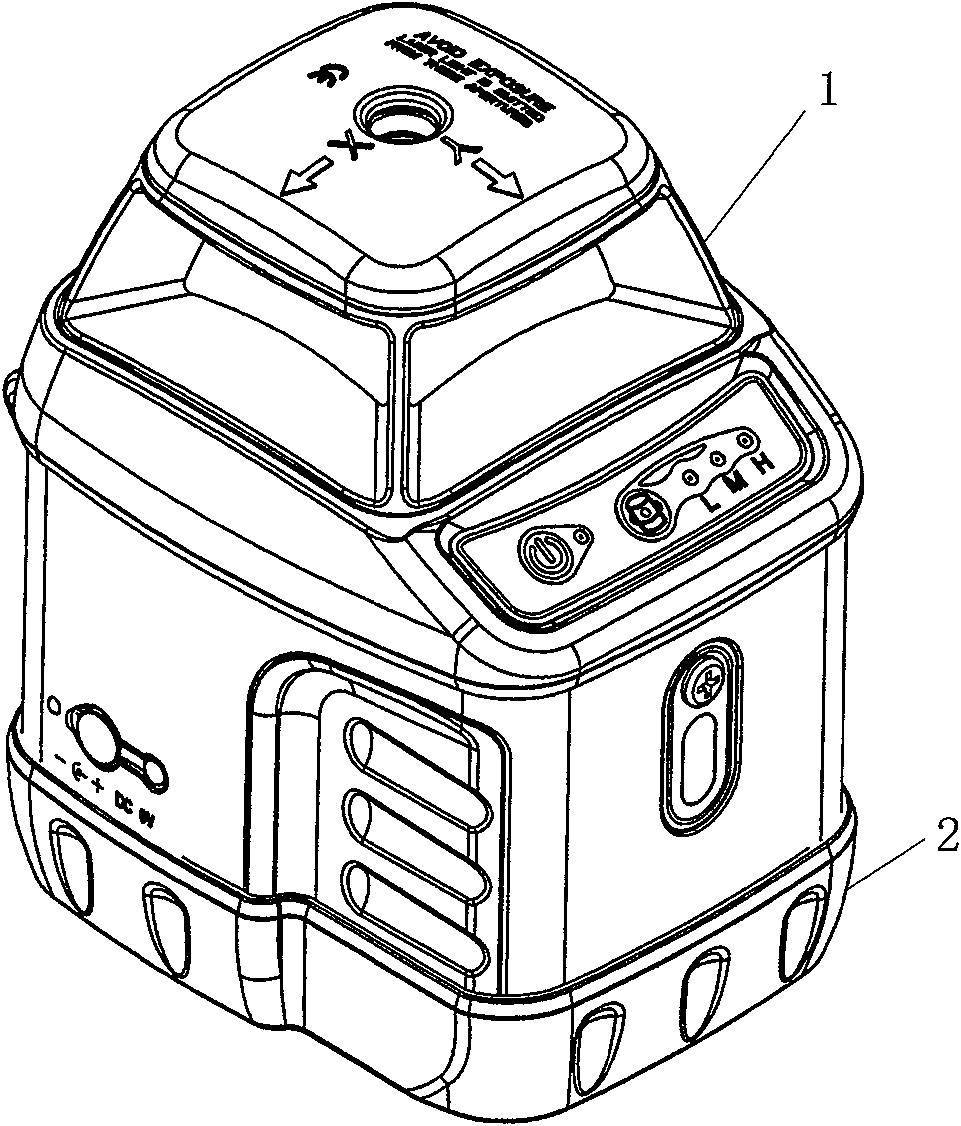

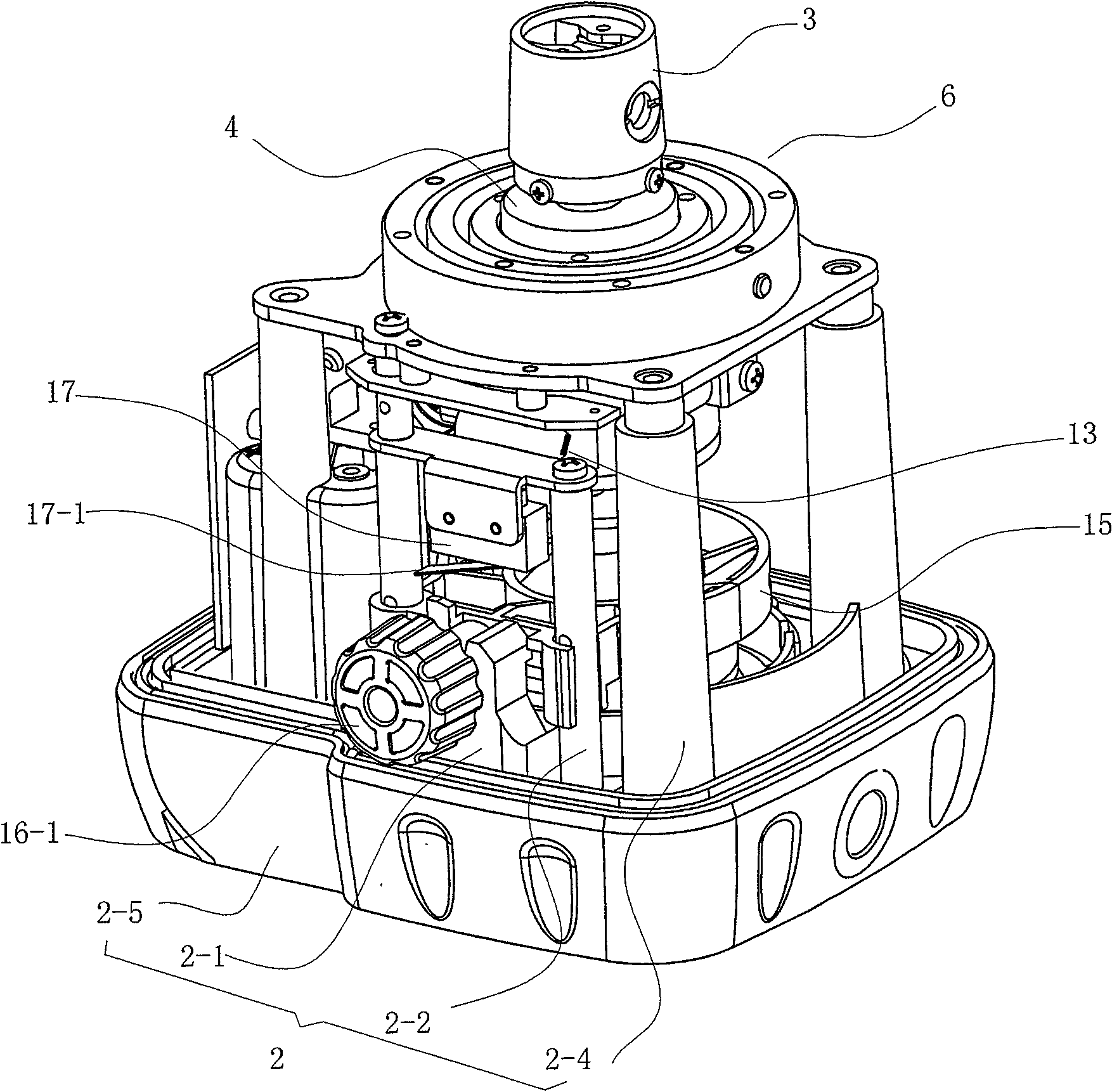

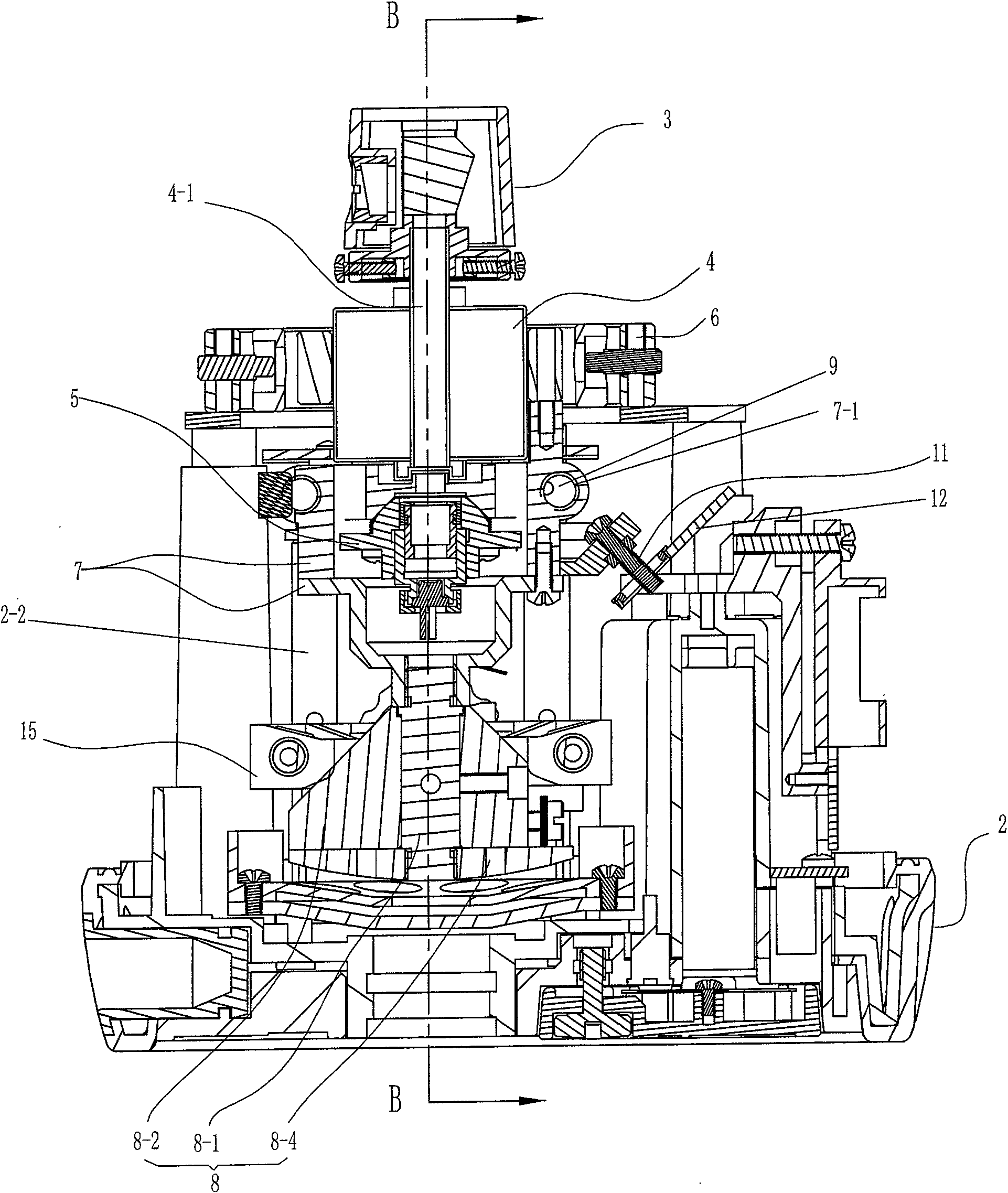

[0027] See Figure 2 to Figure 6 The illustrated embodiment 1 has a housing 1 , a frame 2 , a prism assembly 3 , a motor 4 , and a laser emitter 5 . The above-mentioned frame 2 has a base 2-5, on which a support column 2-4 and a guide rod 2-2 are arranged. The casing 1 and the base 2-5 of the frame 2 cooperate to form the casing of the laser instrument. The base 2-5 is provided with a battery pack to supply power to the motor 4 and the laser transmitter 5 . The laser instrument is equipped with a cardan shaft balance mechanism. The cardan shaft balance mechanism includes an annular component composed of inner, middle and outer rings, and the swing axis between the inner and middle rings is perpendicular to the swing axis between the middle and outer rings. 6 and the weight assembly 8 connected by the connecting piece 7 under the ring assembly. The weight assembly 8 has a central shaft 8-1 whose upper end is connected to the connector 7, and the lower end of the central shaf...

Embodiment 2

[0034] See Figure 7 and Figure 8, on the basis of Embodiment 1, one side of the housing composed of the casing 1 and the base 2-5 of the frame is detachably connected with a side-down base 18, and the seating plane of the side-down base 18 is connected to the frame base 2 The seating plane of -5 is vertical.

[0035] Two brackets 1-1 are arranged on this side of the housing, and a connecting rod 1-2 is fixed between the two brackets 1-1. The sideways base 18 has a bottom plate 18-1, and the bottom plate 18-1 is provided with two shaft frames 18-2 and a screw adjustment column 18-3, and a shaft is arranged between the two shaft frames 18-2, and a fastener is arranged on the shaft 19 and torsion spring 22, fastener 19 is provided with groove 19-1, respectively is provided with groove 18-21 on two shaft frames, groove 18-21 on two shaft frames and groove 19-1 on fastener 19 are in the same On the center line, but the opening directions of the slots 18-21 on the two axle fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com