Method for lowering crystallization point of ammonium nitrate supersaturated solution by using additives

A technology of additives and crystallization points, applied in the direction of explosives, etc., can solve the problems of reduced workability, reduced emulsification, explosive power and limitation of water-gel explosives, etc., and achieves the effects of enhanced frost resistance, power and storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

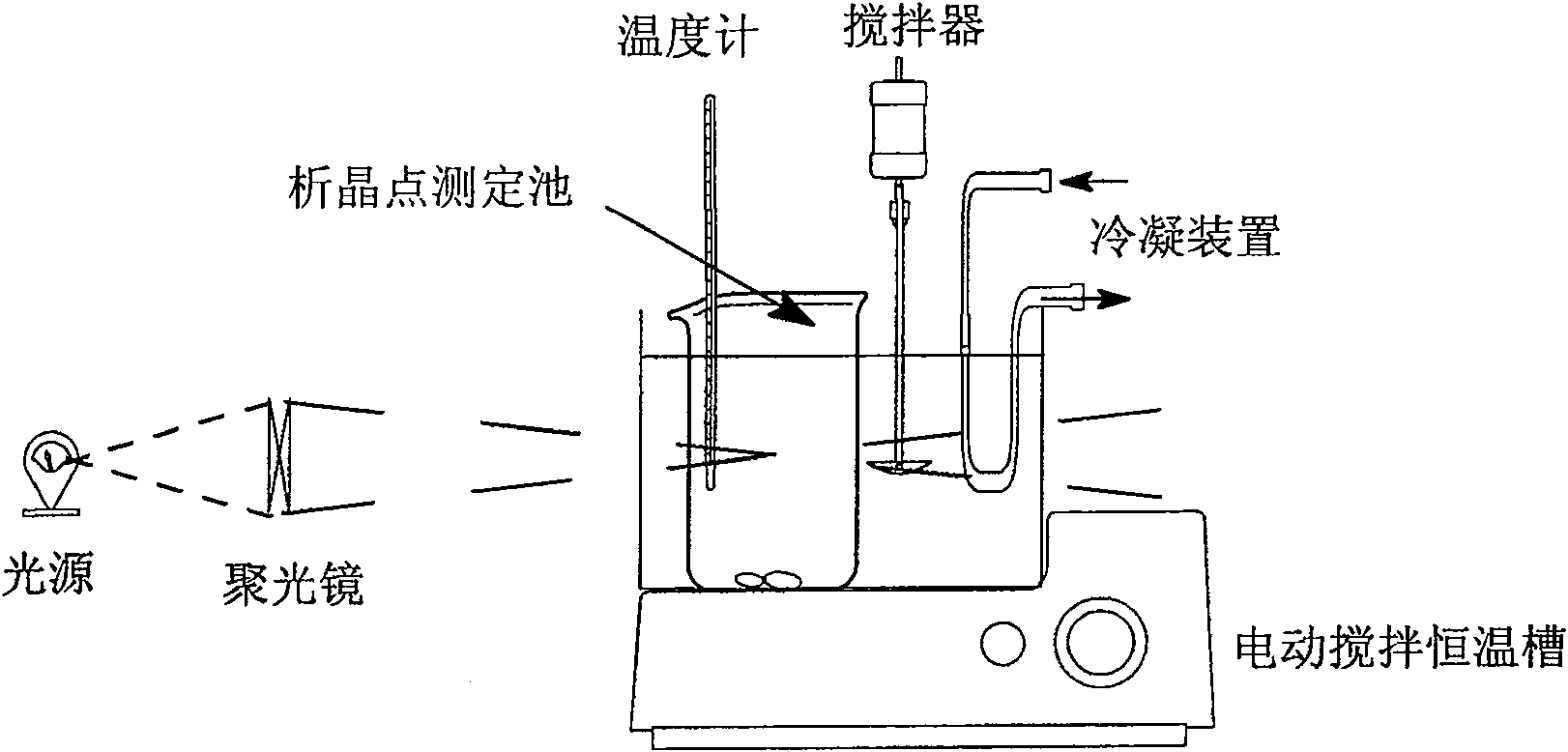

Method used

Image

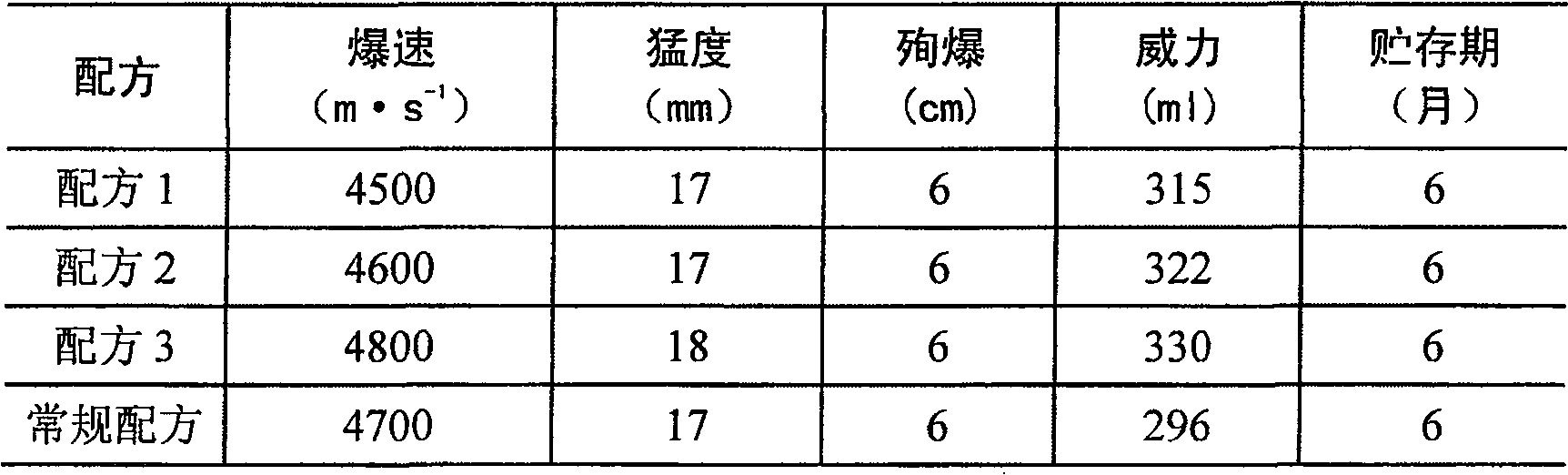

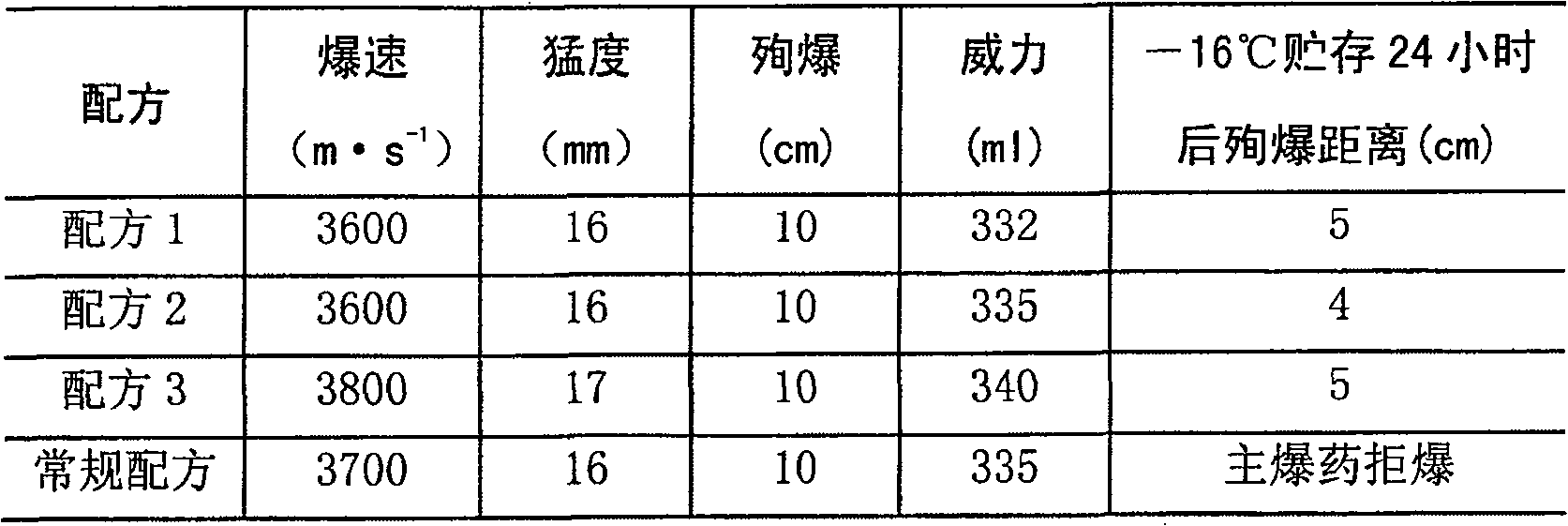

Examples

Embodiment 1

[0020] Add the compound containing 15% of ethylene glycol and 85% of urea into the supersaturated hot solution of ammonium nitrate with a mass concentration of 85%, and the addition amounts are 1%, 4%, 6%, and 8% of the mass of the ammonium nitrate solution, respectively. , Stir and dissolve, and measure the crystallization point of the ammonium nitrate solution according to the above method. The crystallization point of the ammonium nitrate solution is lowered to 103°C, 98°C, 95°C, and 91°C respectively from 118°C of the unadded compound.

Embodiment 2

[0022] Add the compound containing 20% of ethylene glycol and 80% of urea into the supersaturated hot solution of ammonium nitrate with a mass concentration of 85%, and the addition amounts are 1%, 4%, 6%, and 8% of the mass of the ammonium nitrate solution, respectively. , Stir, dissolve, measure the crystallization point of the ammonium nitrate solution according to the above method, the crystallization point of the ammonium nitrate solution is lowered from 118°C of the unadded compound to 101°C, 96°C, 92°C, 90°C respectively.

Embodiment 3

[0024] Add the compound containing 25% of ethylene glycol and 75% of urea into the supersaturated hot solution of ammonium nitrate with a mass concentration of 85%, and the addition amounts are 1%, 4%, 6%, and 8% of the mass of the ammonium nitrate solution, respectively. , Stir, dissolve, measure the crystallization point of the ammonium nitrate solution according to the above method, the crystallization point of the ammonium nitrate solution is lowered from 118°C of the unadded compound to 101°C, 97°C, 94°C, 90°C respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com