Rotary pavement accelerating and loading experiment device

A technology of accelerated loading and experimental equipment, which is applied in the direction of basic structure testing, construction, and basic structure engineering, etc. It can solve problems such as complex structure, high energy consumption, and high noise, so as to reduce energy consumption, improve test efficiency, and reduce noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

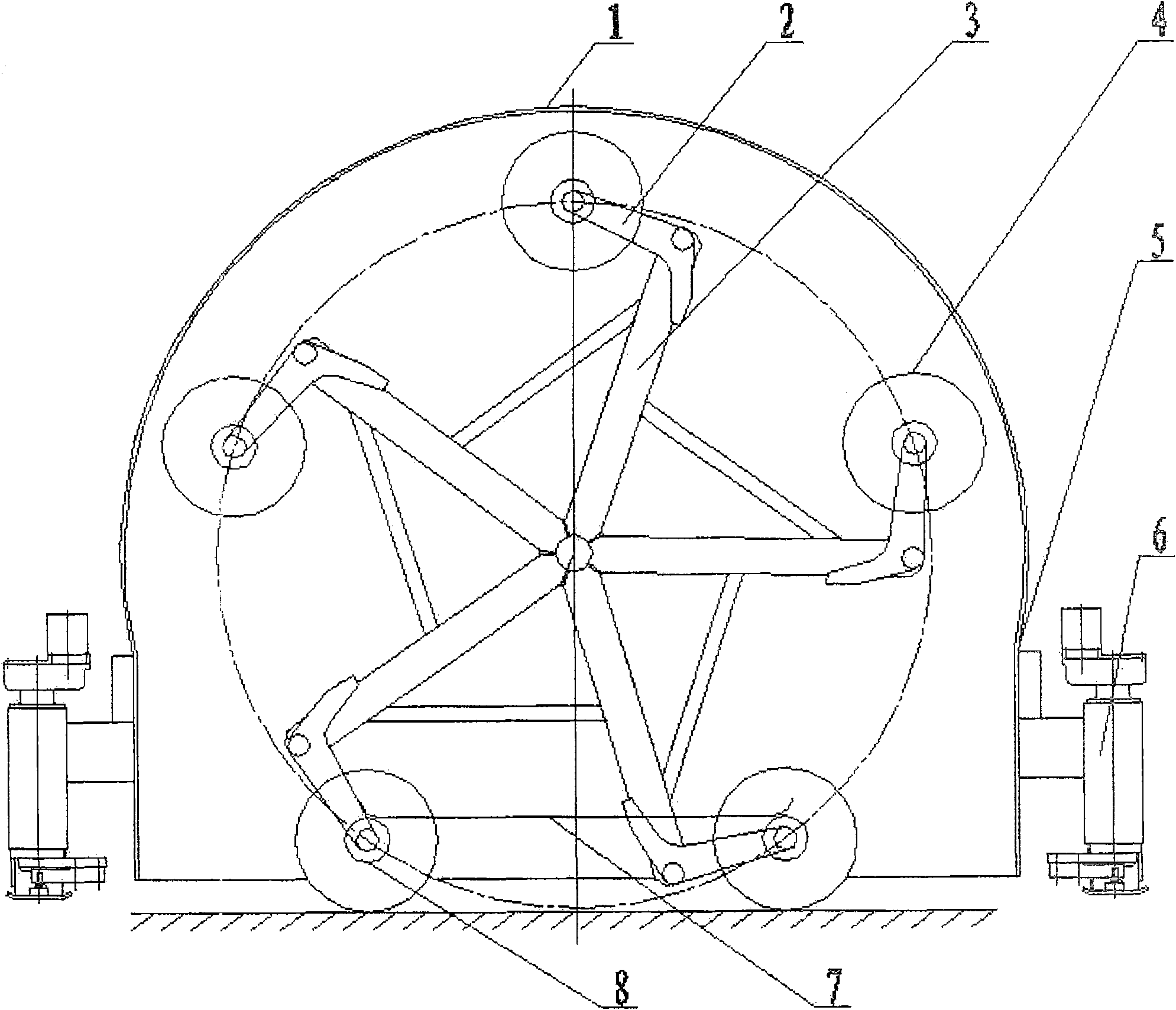

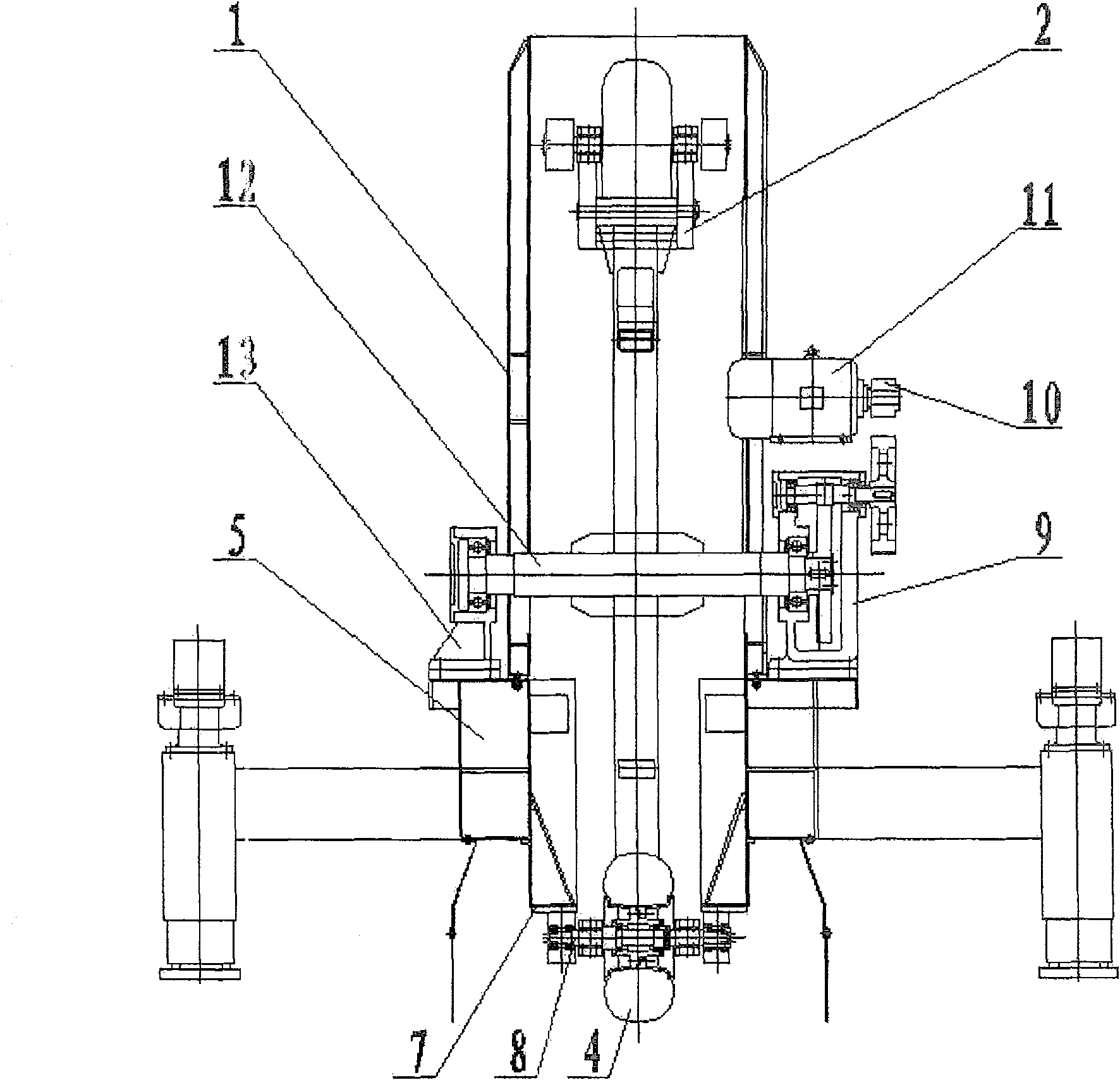

[0015] Combine below figure 1 and figure 2 A rotary road acceleration loading experimental device of the present invention will be described in detail below.

[0016] like figure 1 and figure 2 As shown, a rotary road surface acceleration loading experimental device of the present invention has a structure comprising: a casing 1, a machine base 5, a road surface rolling wheel 4, legs 6, a loading track 7, a loading wheel 8, and a speed reducer 9 , V-belt 10, motor 11, shaft 12, bearing housing 13 and rotary assembly, and the rotary assembly is composed of spokes 3, swing frame 2, and shaft 12.

[0017] The above-mentioned rotary assembly is arranged in the casing 1, and the spokes 3 of the rotary assembly are hinged to the pendulum 2 through the pin shaft, and the pendulum 2 drives the road rolling wheel 4 to rotate clockwise, and sequentially rotates between the loading track 7 and the road rolling wheel 4. Under the action of tire deformation, the road surface is rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com